Method for recovering neodymium and iron from neodymium iron boron oil sludge

A technology of NdFeB and oil sludge, which is applied in the field of NdFeB oil sludge recycling, can solve the problems of human injury, acid-base waste liquid difficult to handle, and not made into industrial products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

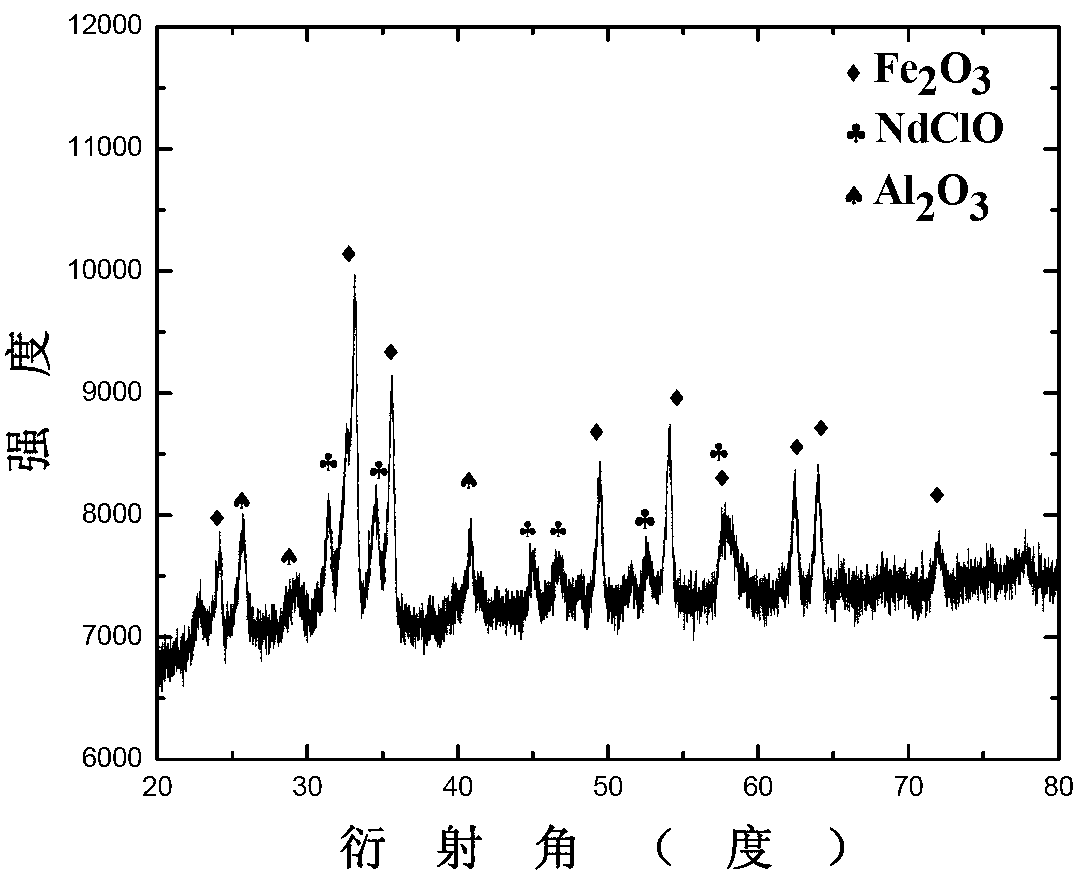

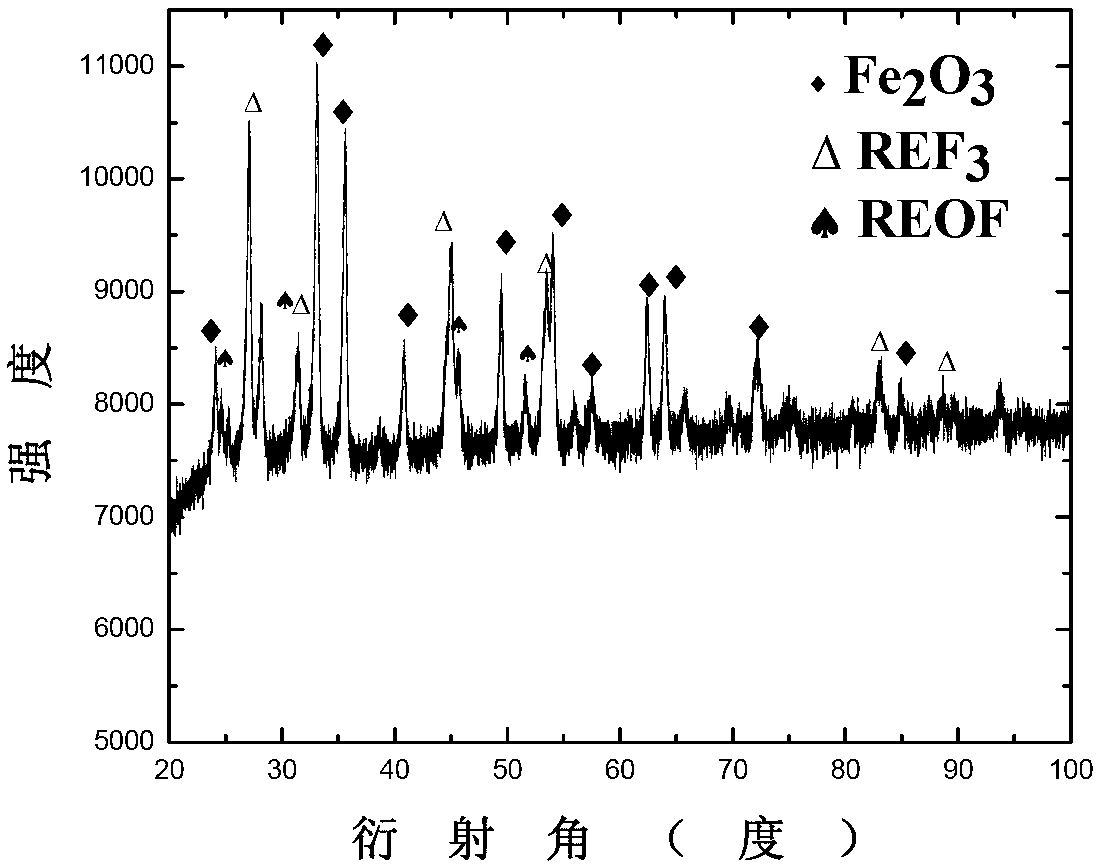

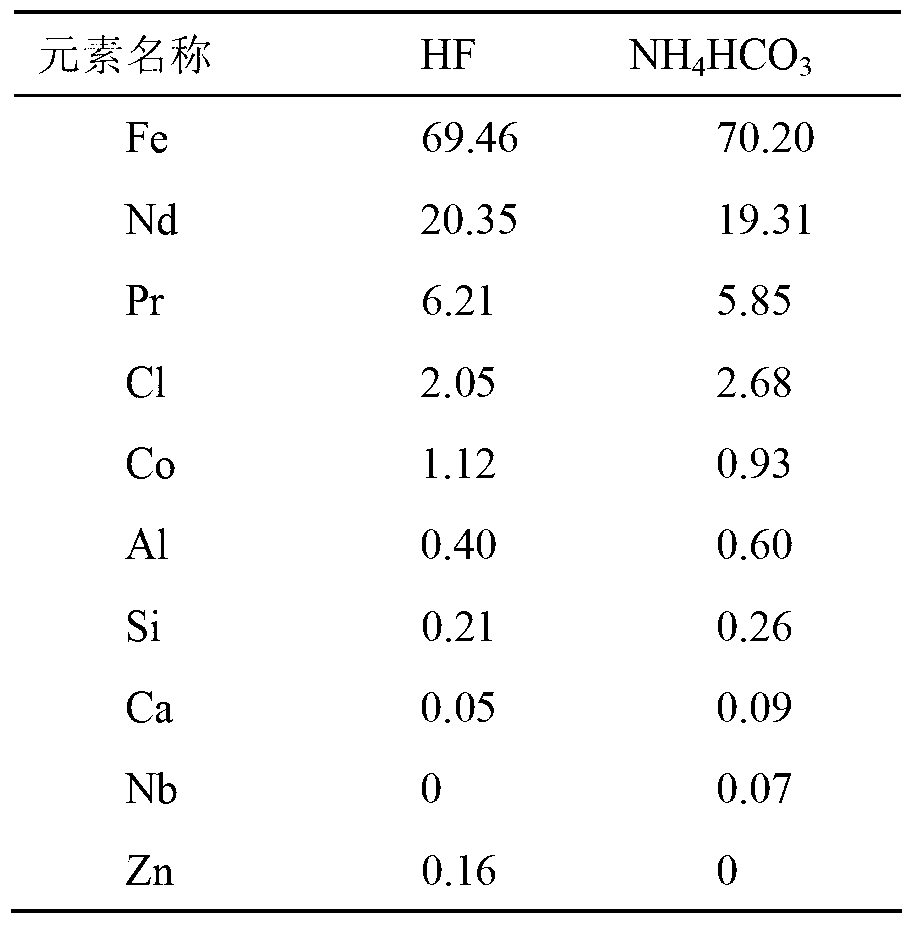

[0021] (1) Take 5g of NdFeB oil sludge, add 60ml of 4mol / L hydrochloric acid to the waste, fully dissolve it, add 30% hydrogen peroxide to the filtrate to oxidize for 10mins and keep stirring, adjust the pH value of the oxidized solution with ammonia water to 5. In the hot solution, slowly add 3 g of 40% hydrofluoric acid solution by mass ratio under constant stirring. Then place it in a water bath at 50-70°C, stir intermittently, and a slimy precipitate forms in the solution. In the heating state, the excess volume ratio of 1:2 ammonia water was slowly added drop by drop into the reactor, stirring intermittently. After the precipitation of iron ions is complete, the solution is centrifuged and washed. Discard the clear and wash solution. The precipitate was centrifuged and dried, then placed in a box furnace, and baked at T=800°C for 90mins.

[0022] Or take 5g of NdFeB oil sludge, add 60ml of 4mol / L hydrochloric acid to the waste, fully dissolve, add 30% hydrogen peroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com