Organic-inorganic hybrid solar cell with passivated organic thin film and preparation method thereof

A technology of solar cells and organic thin films, applied in circuits, photovoltaic power generation, electrical components, etc., to reduce surface defects, enhance charge separation and transmission capacity, and improve photoelectric conversion performance and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

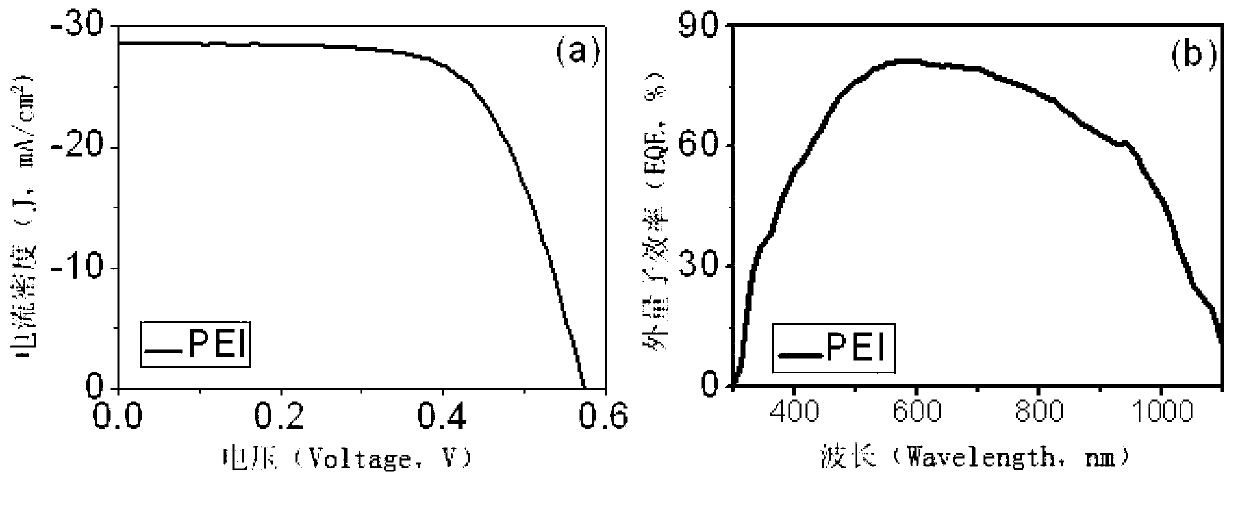

Embodiment 1

[0039]Commercialized n-type single crystal silicon wafers (100) are used with a thickness of 420 microns and a resistivity of 0.9-1.3 ohm cm. The n-type silicon wafers are cleaned and placed in a glove box for alkylation treatment. Immerse the silicon substrate in a saturated phosphorus pentachloride chlorobenzene solution, react at about 110°C for 30 minutes, then wash it twice with chlorobenzene solution and tetrahydrofuran solution respectively, and then dip the cleaned silicon substrate in methylmagnesium chloride ( CH 3 MgCl) in tetrahydrofuran solution (1M), react at 80°C for 8h, and finally soak in dilute hydrochloric acid solution for 40min, blow dry with nitrogen gun, and set aside.

[0040] Using 2-methoxyethanol as solvent, PEI solutions with different concentrations were prepared. Then PEI solutions with different concentrations were spin-coated on the silicon substrate at a speed of 5000 rpm for 1 min, followed by annealing at 100° C. for 10 min to form PEI organ...

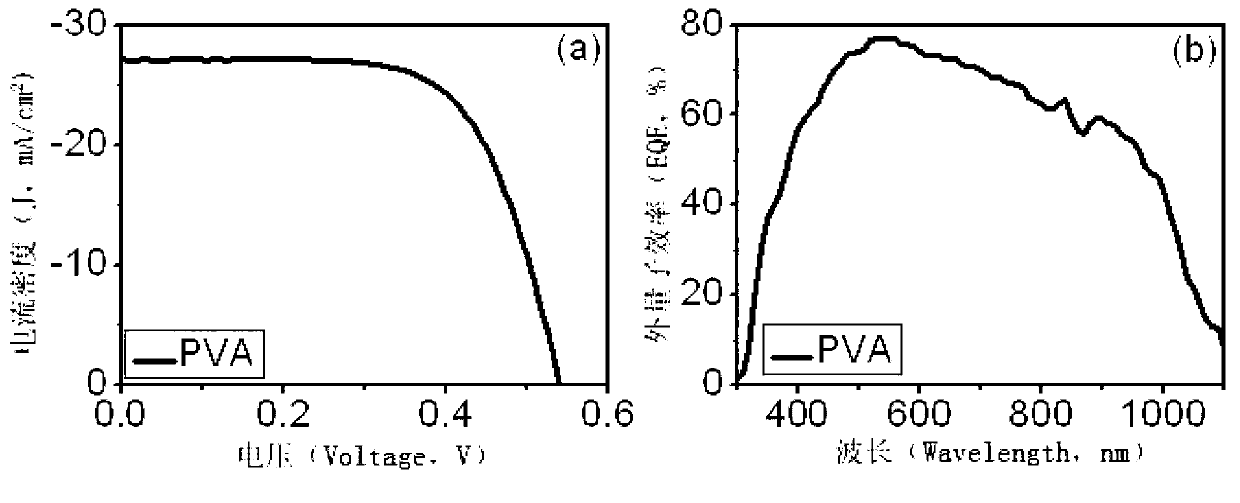

example 2

[0045] Commercialized n-type single crystal silicon wafers (100) are used with a thickness of 420 microns and a resistivity of 0.9-1.3 ohm cm. The n-type silicon wafers are cleaned and placed in a glove box for alkylation treatment. Immerse the silicon substrate in a saturated phosphorus pentachloride chlorobenzene solution, react at about 110°C for 30 minutes, then wash it twice with chlorobenzene solution and tetrahydrofuran solution respectively, and then dip the cleaned silicon substrate in methylmagnesium chloride ( CH 3 MgCl) in tetrahydrofuran solution (1M), react at 80°C for 8h, and finally soak in dilute hydrochloric acid solution for 40min, blow dry with nitrogen gun, and set aside.

[0046] Using deionized water as solvent, PVA solutions with different concentrations were prepared. Then spin-coat PVA solutions with different concentrations on the silicon substrate at a speed of 5000 rpm for 1 min, and then anneal at 100° C. for 10 min to form PVA organic film passi...

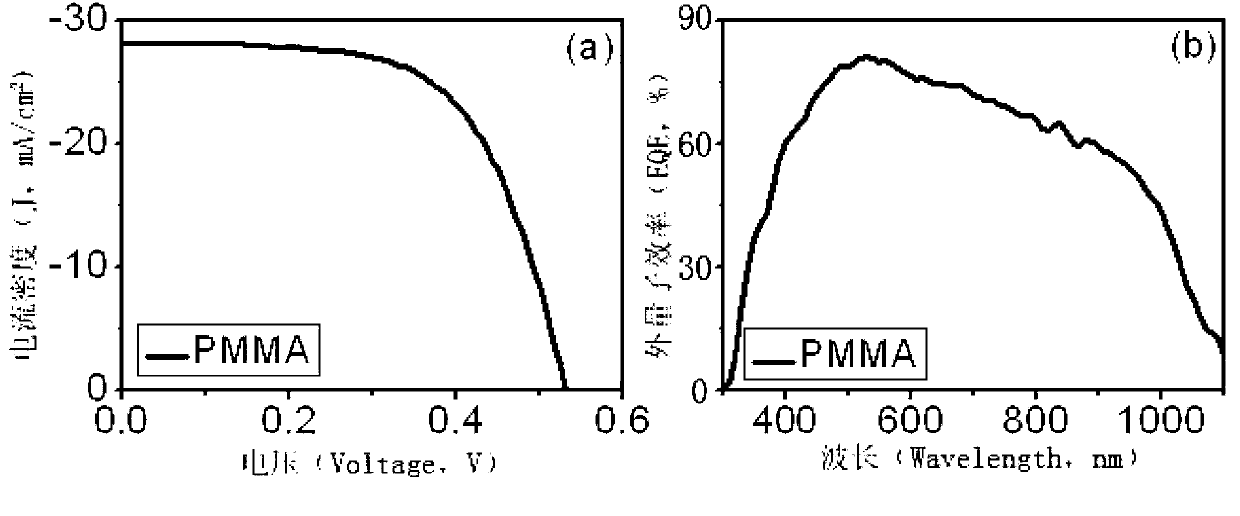

example 3

[0051] Commercialized n-type single crystal silicon wafers (100) are used with a thickness of 420 microns and a resistivity of 0.9-1.3 ohm cm. The n-type silicon wafers are cleaned and placed in a glove box for alkylation treatment. Immerse the silicon substrate in a saturated phosphorus pentachloride chlorobenzene solution, react at about 110°C for 30 minutes, then wash it twice with chlorobenzene solution and tetrahydrofuran solution respectively, and then dip the cleaned silicon substrate in methylmagnesium chloride ( CH 3 MgCl) in tetrahydrofuran solution (1M), react at 80°C for 8h, and finally soak in dilute hydrochloric acid solution for 40min, blow dry with nitrogen gun, and set aside.

[0052] Using toluene as solvent, PMMA solutions with different concentrations were prepared. Then spin-coat PMMA solutions with different concentrations on the silicon substrate at a speed of 4000 rpm for 1 min, and then anneal at 100° C. for 10 min to form PMMA organic film passivatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com