Single-crystal tellurium nanotube and preparation method and application thereof

A tellurium nanometer and single crystal technology, applied in the field of thermoelectric nanometer semiconductor materials, can solve the problems of unsuitability for large-scale industrial production, long reaction time, unfavorable environment, etc., and achieve easy control of size and shape, short reaction time and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Raw materials: analytically pure TeO 2 , absolute ethanol, ethylene glycol (PG).

[0039] 1. Add 0.4788g (3mmol) of TeO 2 and 0.6g of PVP k-30 (Mw=40000) were dispersed in 50ml of ethylene glycol, and then the mixture was transferred to a three-necked flask with a capacity of 100ml, magnetically stirred and heated to 135°C, the solution consisted of a milky white suspension It gradually becomes a colorless and transparent clear solution.

[0040] 2. Continue to stir and heat up to 200°C, add 0.3g of NaOH to the three-necked flask, the clear solution gradually turns into a gray-black solution, keep the temperature at 200°C for 25 minutes, and then naturally cool to room temperature (this process is always about 20r / s stirring rate).

[0041] 3. Centrifuge the gray-black solution at a speed of 8500 rpm, pour off the upper liquid, and then use absolute ethanol to ultrasonically disperse the lower precipitate, and then perform centrifugal separation. Repeat the above ste...

Embodiment 2

[0044] Raw material: analytically pure TeO 2 , absolute ethanol, ethylene glycol (PG).

[0045] 1. Add 0.9576g (6mmol) of TeO 2 and 1.2g of PVP k-30 (Mw=40000) were dispersed in 100ml of ethylene glycol, and then the mixture was transferred to a three-necked flask with a capacity of 250ml, magnetically stirred and heated to 135°C, the solution consisted of a milky white suspension It gradually becomes a colorless and transparent clear solution.

[0046] 2. Continue to stir and heat up to 200°C, add 0.6g of NaOH to the three-necked flask, the clear solution gradually turns into a gray-black solution, keep the temperature at 200°C for 25 minutes, and then cool naturally to room temperature (this process is always about Stirring rate of 1200r / min).

[0047] 3. Centrifuge the gray-black solution at a speed of 8500 rpm, pour off the upper liquid, and then use absolute ethanol to ultrasonically disperse the lower precipitate, and then perform centrifugal separation. Repeat the ab...

Embodiment 3

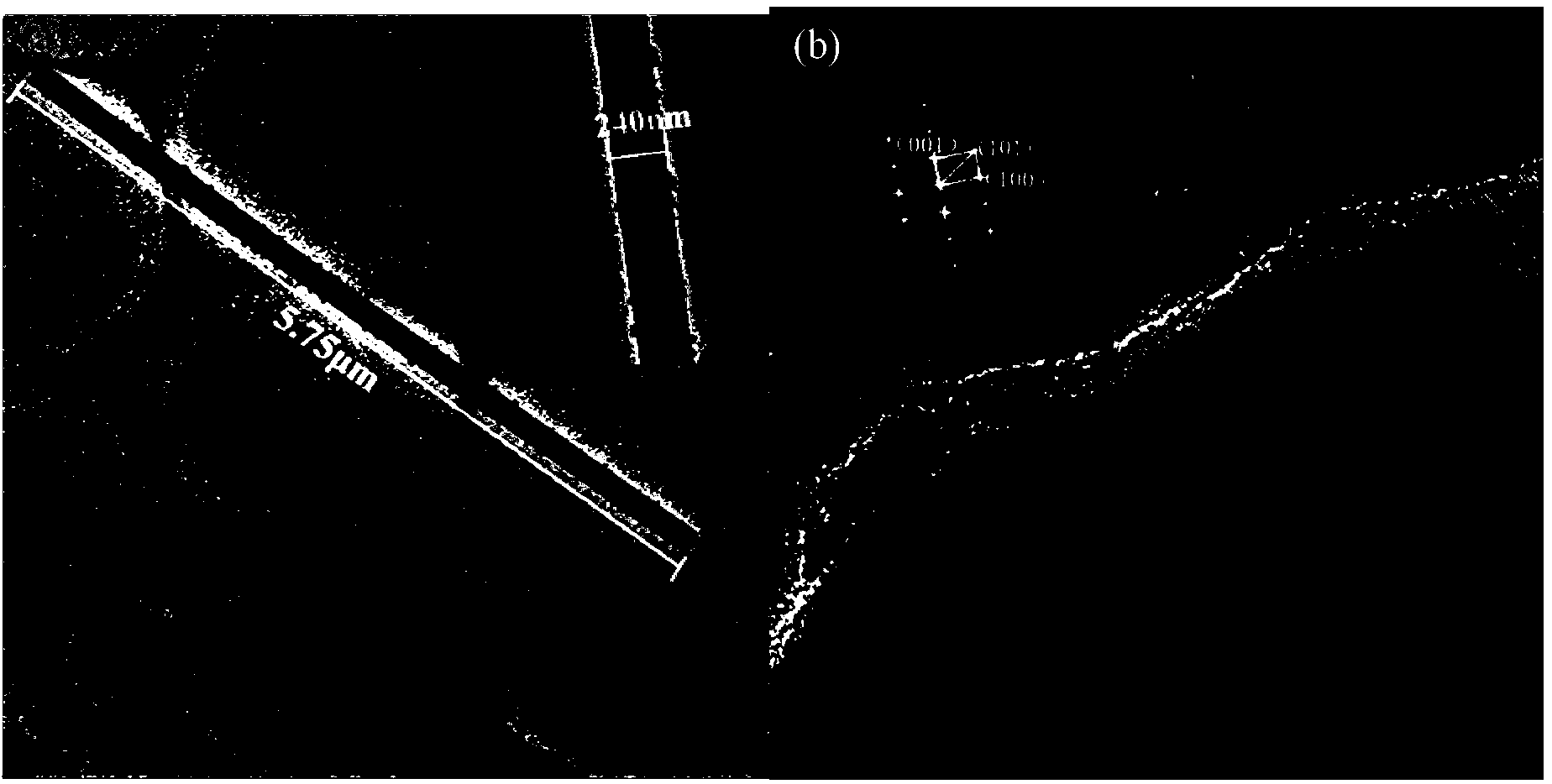

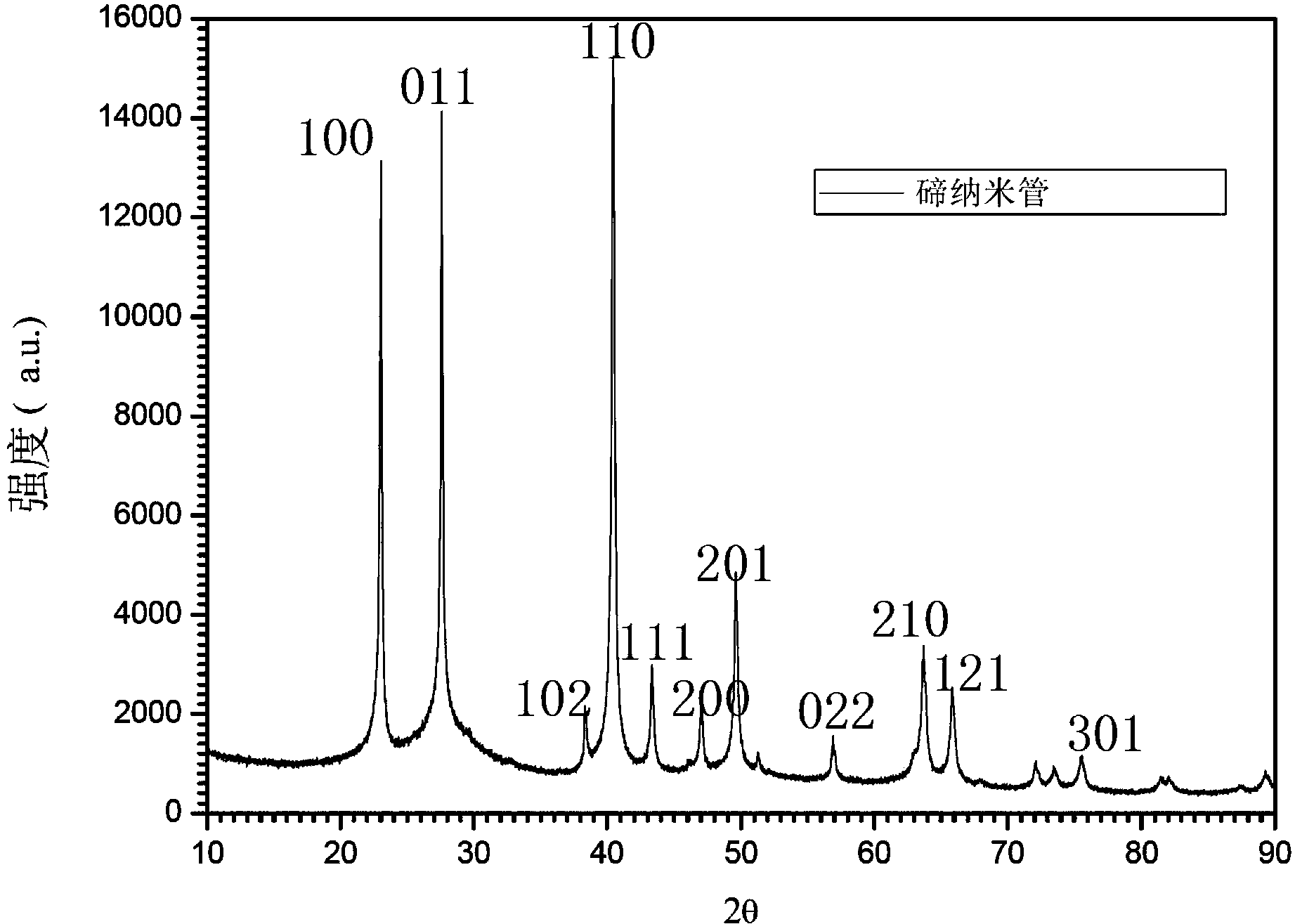

[0050] The steps are the same as Example 1, the difference is that step 2) continue to stir and raise the temperature to 185°C, add 0.3g of NaOH to the three-necked flask, the clear solution gradually turns into a gray-black solution, and keep the temperature at 185°C for 25 minutes. The obtained experimental results are slightly different from Example 1. The length is about 5 μm, the diameter is about 171 nm, and the wall thickness is about 30 nm. The surface of the tellurium nanotubes is rough and uneven, indicating that lowering the synthesis temperature will reduce the reaction rate, which is not conducive to the full reaction of various substances. , the synthesized tellurium nanotubes are small in size and rough in surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com