Lithium iodide organic electrolyte for lithium iron battery and preparation method thereof

An organic electrolyte and lithium iodide technology, which is applied in the field of lithium batteries, can solve problems such as scrapping, poor safety performance, and increased viscosity of the electrolyte, so as to reduce costs, meet safety and environmental protection requirements, and improve the effect of low-temperature discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

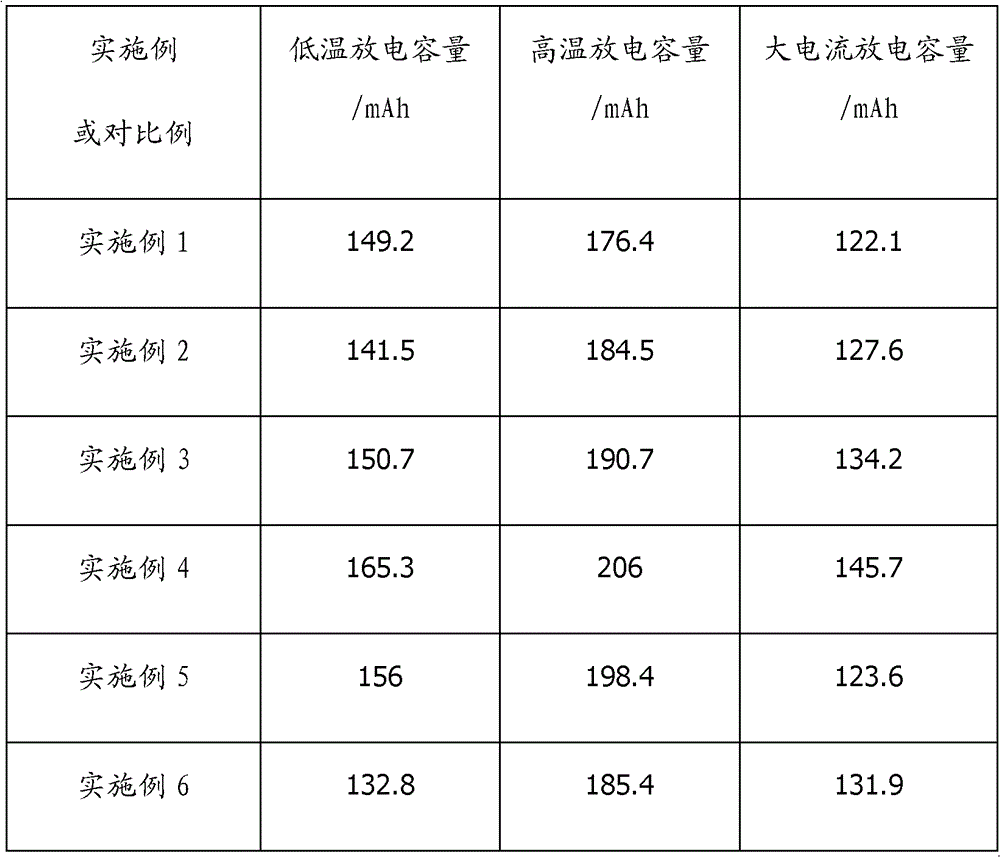

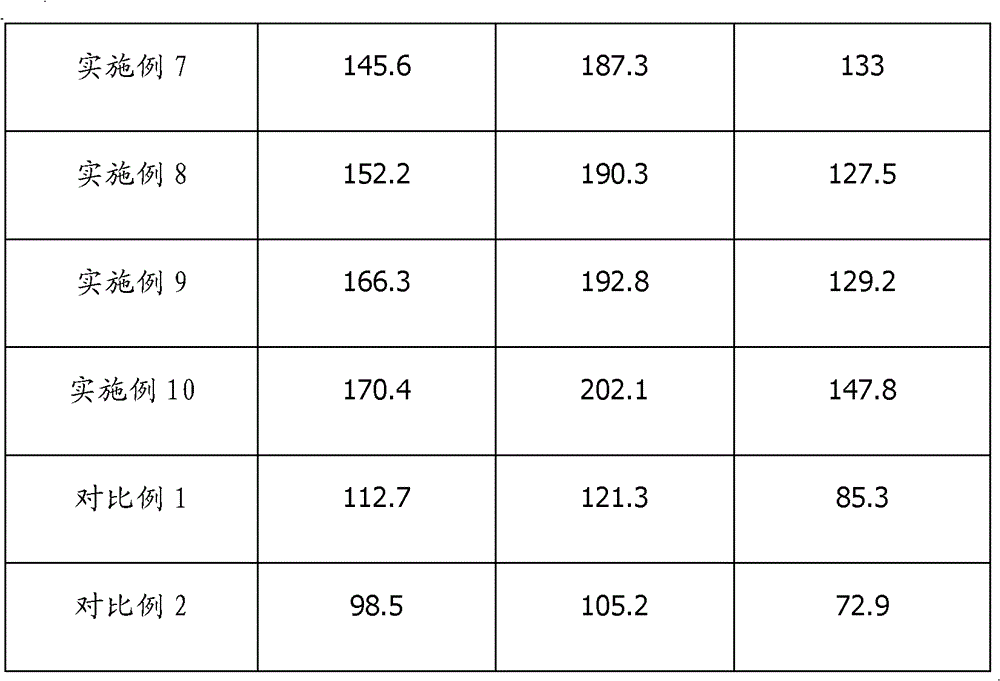

Examples

Embodiment 1

[0035] Mix ethylene glycol dimethyl ether, 30% 1,3-dioxane, and 25% dimethyl sulfoxide accounting for 30% of the mass fraction of the electrolyte, and then add 1.5% 2,6-di-tert-butyl-4-methylphenol and 3% 3-methylisoxazole, the above raw materials are dehydrated with ordinary molecular sieves before mixing; Anhydrous lithium iodide with a fraction of 8% and lithium trifluoromethanesulfonate with a fraction of 2.5% are completely dissolved and then dehydrated and adsorbed using lithiated molecular sieves for 48 hours. When the moisture reaches 60ppm, filter to obtain lithium iodide organic electrolyte .

Embodiment 2

[0037] Mix 1,3-dioxane, 10% tetrahydrofuran, 20% sulfolane, and 25% vinyl sulfone accounting for 30% of the electrolyte mass fraction, and add 0.5% of the electrolyte mass fraction to the mixed solution. Butyl hydroquinone and 1.5% 5-methylisoxazole, above-mentioned raw materials all use common molecular sieve to carry out dehydration earlier before mixing; Add anhydrous lithium iodide and 3% lithium bis(trifluoromethylsulfonyl)imide is completely dissolved and then dehydrated and adsorbed with lithiated molecular sieves for 72 hours. When the moisture reaches 65 ppm, it is filtered to obtain a lithium iodide organic electrolyte.

Embodiment 3

[0039] Mix ethylene glycol dimethyl ether, 20% sulfolane, and 30% dimethyl sulfoxide accounting for 30% of the mass fraction of the electrolyte, and add 2,6-ditertiary Butyl-4-methylphenol and 1% 3,5-dimethyl-4-iodoisoxazole, the above raw materials are all dehydrated with ordinary molecular sieves before mixing; Anhydrous lithium iodide with a fraction of 17% is completely dissolved and then dehydrated and adsorbed with lithiated molecular sieves for 72 hours. When the moisture reaches 50 ppm, it is filtered to obtain a lithium iodide organic electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com