Photocatalytic water splitting hydrogen production material CdS/Ba0.9Zn0.1TiO3 and preparation method thereof

A technology for photocatalysis and water splitting, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of fast recombination rate of photo-induced holes and photo-generated electrons, low quantum efficiency, and pollutant adsorption Poor performance and other problems, to achieve the effect of easy reuse, simple operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

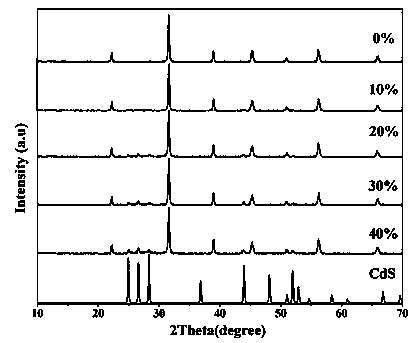

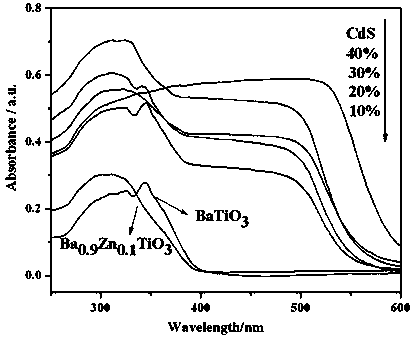

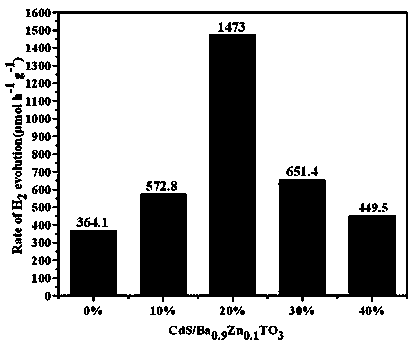

[0015] 1. Compound Ba 0.9 Zn 0.1 TiO 3 Synthesis

[0016]Dissolve 9 mmol (2.4609 g) of barium acetate and 1 mmol (0.2195 g) of zinc acetate in 10 ml of acetic acid solution with a concentration of 36% (acetic acid accounts for the volume ratio of the solution), and stir for 30 minutes to obtain solution A . Then, 10 mmol of tetra-n-butyl titanate was dissolved in 5 ml of isopropanol, and 1.5 ml of glacial acetic acid was added and stirred to obtain B solution. Slowly add solution B to solution A, and stir for 30 minutes to obtain solution C. The C solution was charged into a 25 ml polytetrafluoroethylene reaction kettle, and put into a muffle furnace at 100° C. for hydrothermal reaction for 2 hours. The obtained xerogel was ground and calcined at 900°C for 10 hours to obtain Ba 0.9 Zn 0.1 TiO 3 powder.

[0017] 2. Catalyst 10%CdS / Ba 0.9 Zn 0.1 TiO 3 Synthesis

[0018] Weigh 2 g of the prepared Ba 0.9 Zn 0.1 TiO 3 Disperse the powder in 30 ml of water, stir eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com