Cyclic biodegradation aliphatic polyester and preparation method thereof

An aliphatic polyester, biodegradable technology, applied in the production of bulk chemicals, etc., to achieve mild reaction conditions and mild specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step (1): Add propynyl alcohol and L-lactide with a molar ratio of 1:40 into a specific microwave reaction tube after silanization, and add stannous octoate with 0.5% of the mass of L-lactide monomer, Repeatedly evacuate and pass N 2 After heating for about 1 hour to melt and mix the reaction system uniformly, place the reaction tube in a DISCOVER microwave reactor and polymerize under the assistance of microwaves. The reaction temperature is set at 100°C, the microwave power is 30W, and the reaction time is 20 minutes; After the reaction, the solid crude product was dissolved in chloroform, precipitated with absolute ethanol, and then dried in vacuum at 45°C to constant weight to obtain single-terminal alkynylated poly(L-lactide).

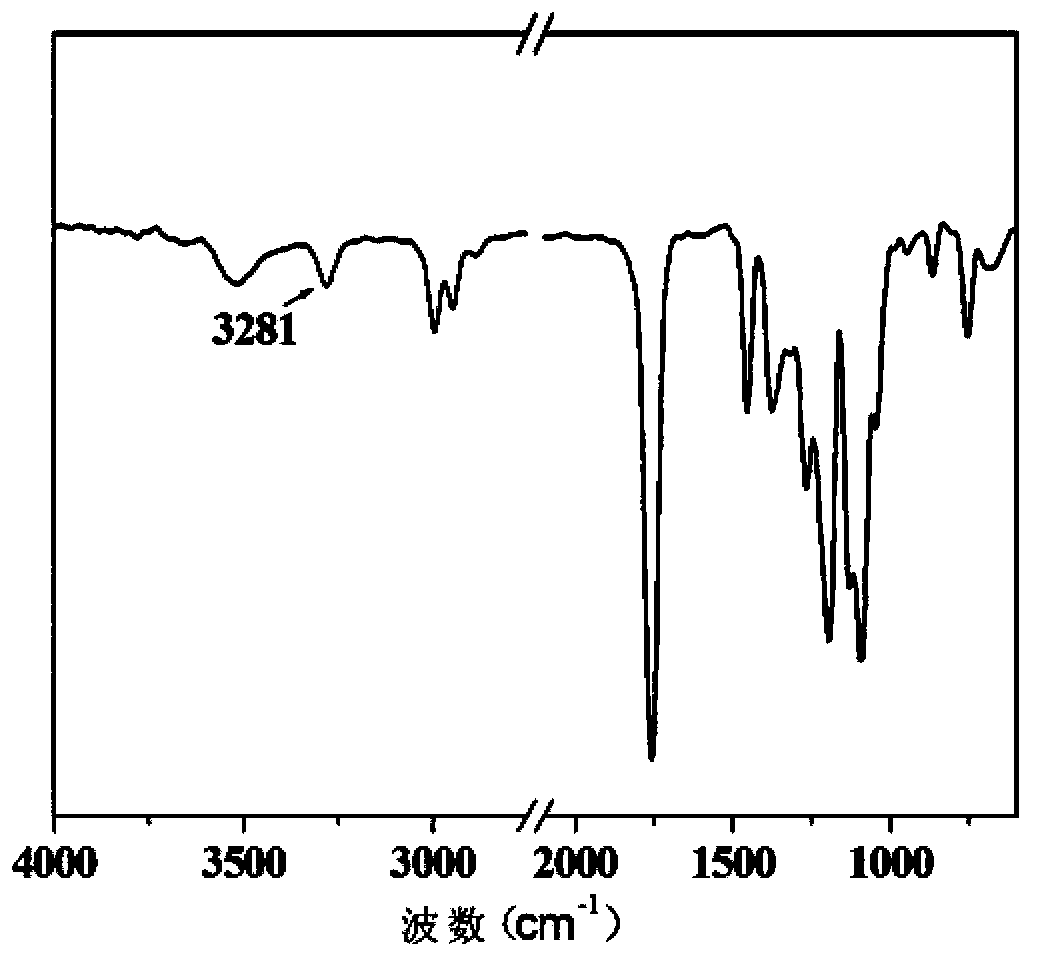

[0038] The composition and structure of the single-end alkynylated poly(L-lactide) synthesized in this example were characterized by infrared spectroscopy. figure 1 . It can be observed from the figure that the 1756cm -1 The characterist...

Embodiment 2

[0044] Step (1): Add propynyl alcohol and ε-caprolactone with a molar ratio of 1:40 into a specific microwave reaction tube after silanization, and add stannous octoate with 1% mass of ε-caprolactone monomer, Repeatedly evacuate and pass N 2 After heating for about 1 hour to melt and mix the reaction system uniformly, the reaction tube was placed in a DISCOVER microwave reactor and polymerized under the assistance of microwaves. The reaction temperature was set at 110°C, the reaction time was 15 minutes, and the microwave power was 50W. It was a transparent viscous liquid, then heated to 140°C, and continued to react for 20 minutes; after the reaction, the solid crude product was dissolved in chloroform, precipitated in absolute ethanol, and then dried in vacuum at 45°C to constant weight to obtain a of poly(ε-caprolactone).

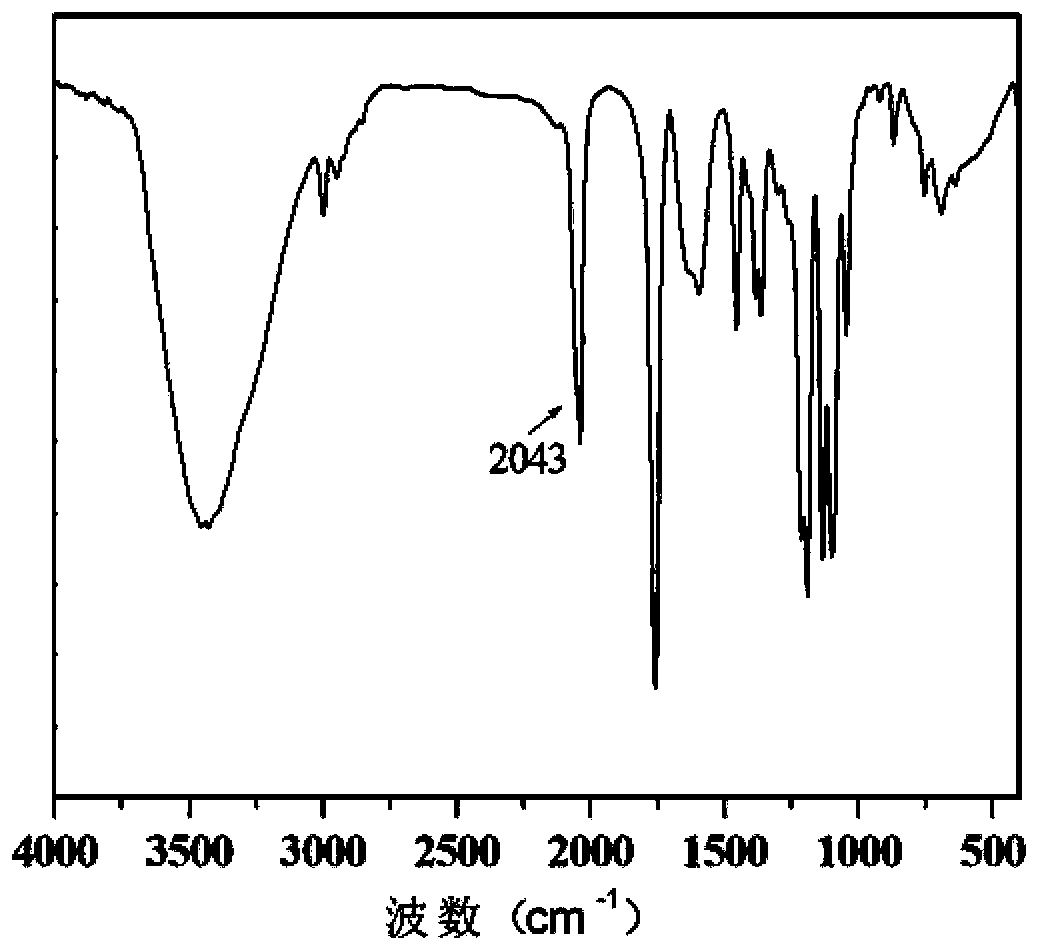

[0045] Step (2): Weigh 1 mmol of single-terminal alkynylated poly(ε-caprolactone) obtained in step (1), put it in a 100 mL three-neck flask, add 50 mL ...

Embodiment 3

[0050] Step (1): Add 3,5-dimethyl-1-hexyn-3-ol and δ-valerolactone with a molar ratio of 1:80 into a specific microwave reaction tube after silanization, and add δ- Tin lactate with 2% mass of valerolactone monomer, repeated vacuuming and N 2 After heating for about 1 hour to melt and mix the reaction system uniformly, the reaction tube was placed in a DISCOVER microwave reactor and polymerized under the assistance of microwaves. The reaction temperature was set at 90°C, the reaction time was 60 minutes, and the microwave power was 50W. It was a transparent viscous liquid, and immediately heated to 140°C, and continued to react for 30 minutes; the solid crude product was dissolved in chloroform, precipitated in absolute ethanol, and then vacuum-dried at 45°C for 24 hours, and then vacuum-dried at 45°C to constant weight. Single-ended alkynylated poly(δ-valerolactone) was obtained.

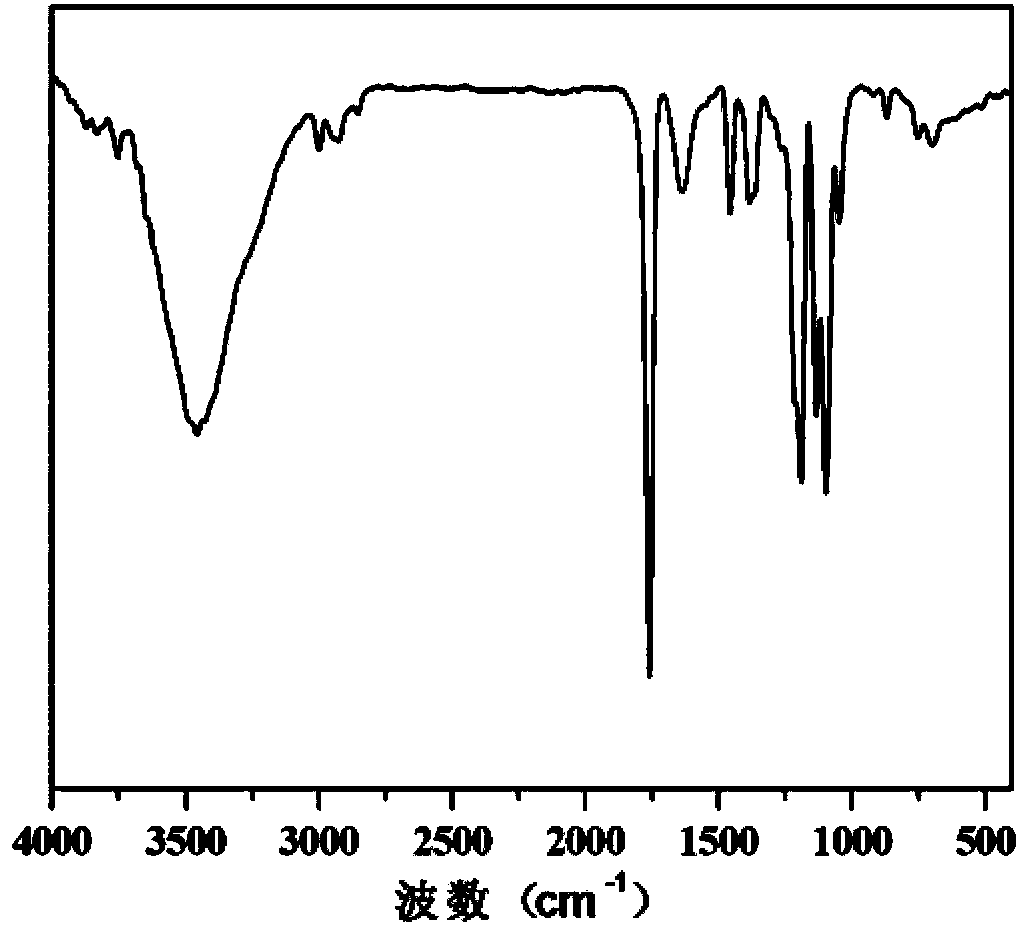

[0051] Step (2): Weigh 1 mmol of the poly(δ-valerolactone) modified by the terminal alkyne gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com