Method for preparing nanocellulose fiber optical transparent membrane material from peanut hulls

A nanocellulose and fiber optics technology, applied in fiber raw material processing, textile and papermaking, etc., can solve the problems of pollution, throwing away, waste of resources and environment, etc., and achieve the effect of simple and feasible method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

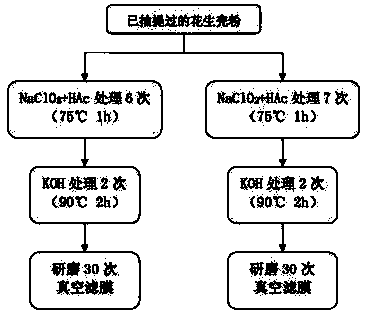

Embodiment 1

[0038] (1) Accurately weigh 10g of extracted peanut shell powder and put it into a 600ml beaker, add 500ml of distilled water; (2) Weigh 4.5g of sodium chlorite and measure 4ml of glacial acetic acid. Put it in a heat-collecting magnetic heating stirrer for 6 times, each time for 1 hour, because the heating reaction will release chlorine gas, so add a layer of plastic wrap to the mouth of the beaker to seal it, filter it with a Buchner funnel after treatment, and wash the residue repeatedly with distilled water , until the solution is neutral; (3) Weigh 10g of potassium hydroxide, add 500ml of distilled water to make a 2% solution, and put it in a collector type magnetic heating stirrer at a temperature of 90°C for 2 times, Treat for 2 hours each time, filter with a Buchner funnel after treatment, and wash the residue repeatedly with distilled water until the solution is neutral; (4) Grind the chemically treated peanut shell powder cellulose into a 1% solution for 30 times and ...

Embodiment 2

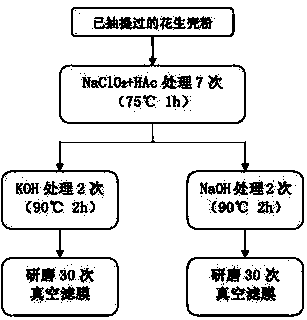

[0039] Example 2: figure 2 Effect of acid treatment times on experiment

[0040] (1) Accurately weigh 10g of the extracted peanut shell powder and put it into a 600ml beaker, add 500ml of distilled water; (2) Weigh 4.5g of sodium chlorite and measure 4ml of glacial acetic acid. Put it in a heat-collecting magnetic heating stirrer for 7 times, each time for 1 hour, because the heating reaction will release chlorine gas, so add a layer of plastic wrap to the mouth of the beaker to seal it, filter it with a Buchner funnel after treatment, and wash the residue repeatedly with distilled water , until the solution is neutral; (3) Weigh 10g of potassium hydroxide, add 500ml of distilled water to make a 2% solution, filter it with a Buchner funnel after treatment, and wash the residue repeatedly with distilled water until the solution is neutral ; (4) The chemically treated peanut shell powder cellulose was made into a 1% solution and ground for 30 times with a vacuum filter to obt...

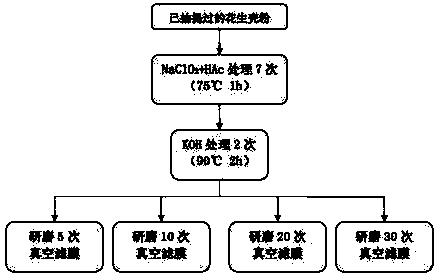

Embodiment 3

[0042] (1) Accurately weigh 10g of the extracted peanut shell powder and put it into a 600ml beaker, add 500ml of distilled water; (2) Weigh 4.5g of sodium chlorite and measure 4ml of glacial acetic acid. Put it in a heat-collecting magnetic heating stirrer for 7 times, each time for 1 hour, because the heating reaction will release chlorine gas, so add a layer of plastic wrap to the mouth of the beaker to seal it, filter it with a Buchner funnel after treatment, and wash the residue repeatedly with distilled water , until the solution is neutral; (3) Weigh 10g of potassium hydroxide, add 500ml of distilled water to make a 2% solution, and put it in a collector type magnetic heating stirrer at a temperature of 90°C for 2 times, Treat for 2 hours each time, filter with Buchner funnel after treatment, and wash the residue repeatedly with distilled water until the solution is neutral; (4) Grind the chemically treated peanut shell powder cellulose into a 1% solution for 30 times an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com