Method for continuously extracting effective components in cyperus alternifolius leaves by using ultrasonic-assisted supercritical carbon dioxide

A technology for carbon dioxide and active ingredients, which is applied in the field of continuous extraction of active ingredients in windmill grass leaves by ultrasonic-assisted supercritical carbon dioxide extraction technology, can solve the problems of complicated and tedious processes, large amount of organic solvents, residual toxic and harmful solvents, etc., and achieves a simple process flow. Reliable, short cycle times and low solvent usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

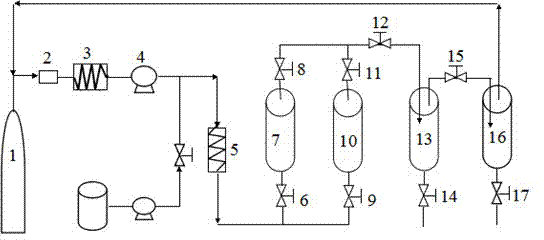

[0029] After mixing 1 kg of dried 40-mesh windmill grass leaf powder with 200ml of 80% edible ethanol (the weight ratio of the two is about 100:17), put it in an ultrasonic instrument at 35°C and 53KHz for 20 minutes of ultrasonic treatment, The raw materials are taken out and put into the extraction kettle I7 and the extraction kettle II10 of the supercritical carbon dioxide extraction equipment. Set the extraction pressure to 35MPa, the extraction temperature to 50°C, the temperature of the separation kettle I13 to 55°C, and the pressure to 10MPa, the pressure of the separation kettle II16 to 4.5Mpa, and the temperature of the separation kettle II16 to 35°C. After dynamic extraction for 2 hours, the extract was collected and concentrated to obtain 57g of Herba Fructus extract.

Embodiment 2

[0031] After mixing 1 kg of dried 100-mesh windmill grass leaf powder with 600ml of 95% edible ethanol (the weight ratio of the two is about 100:48), put it in an ultrasonic instrument at 60°C and 37KHz for 60 minutes of ultrasonic treatment, The raw materials are taken out and put into the extraction kettle I7 and the extraction kettle II10 of the supercritical carbon dioxide extraction equipment. The extraction pressure is set to 22MPa, the extraction temperature is 40°C, the temperature of the separation tank I13 is 45°C, the pressure is 8MPa, the pressure of the separation tank II16 is 5Mpa, and the temperature of the separation tank II16 is 40°C. Static extraction for 1 hour, dynamic extraction for 1 hour, the extract was collected and concentrated to obtain 52g of Herba Fructus extractum.

Embodiment 3

[0033] After mixing 1 kg of dry 60-mesh windmill grass leaf powder with 1000 ml of 70% edible ethanol (the weight ratio of the two is about 100:87), put it in an ultrasonic instrument at 40 °C and 40 KHz for 30 minutes, and then put The raw materials are taken out and put into the extraction kettle I7 and the extraction kettle II10 of the supercritical carbon dioxide extraction equipment. The extraction pressure is set to 40MPa, the extraction temperature is 65°C, the temperature of the separation tank I13 is 75°C, the pressure is 6MPa, the pressure of the separation tank II16 is 5Mpa, and the temperature of the separation tank II16 is 45°C. Static extraction for 0.5 hours, dynamic extraction for 1.5 hours, the extract was collected and concentrated to obtain 60 g of Herba chinensis extract.

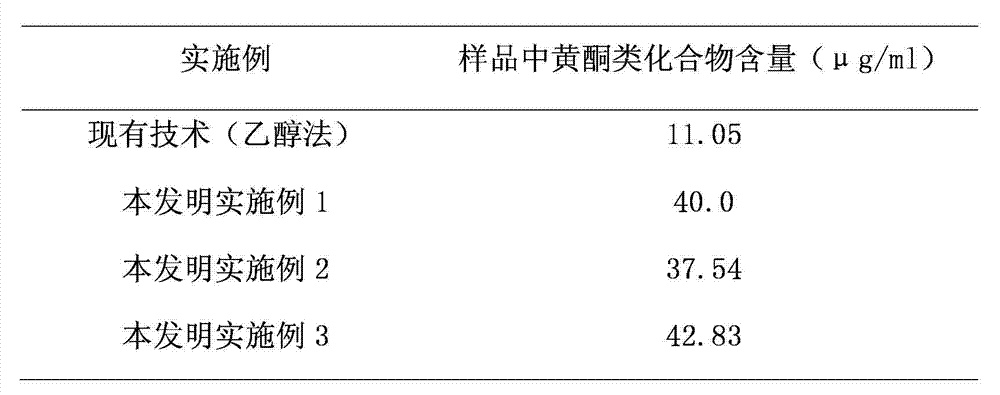

[0034] The following is to observe the content of flavonoids in the windmill grass leaf extract obtained by the comparative test, to observe the ultrasonic assisted supercritical CO 2 A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com