Boron aluminate-based blue fluorescent powder, preparation method and application

A blue phosphor and boro-aluminate technology, applied in the field of rare earth luminescent materials, can solve the problems that cannot well meet the needs of actual production, the europium ions are not easy to be fully reduced, the performance of white LEDs is reduced, etc., and achieves easy industrialization. Production, ease of operation, reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

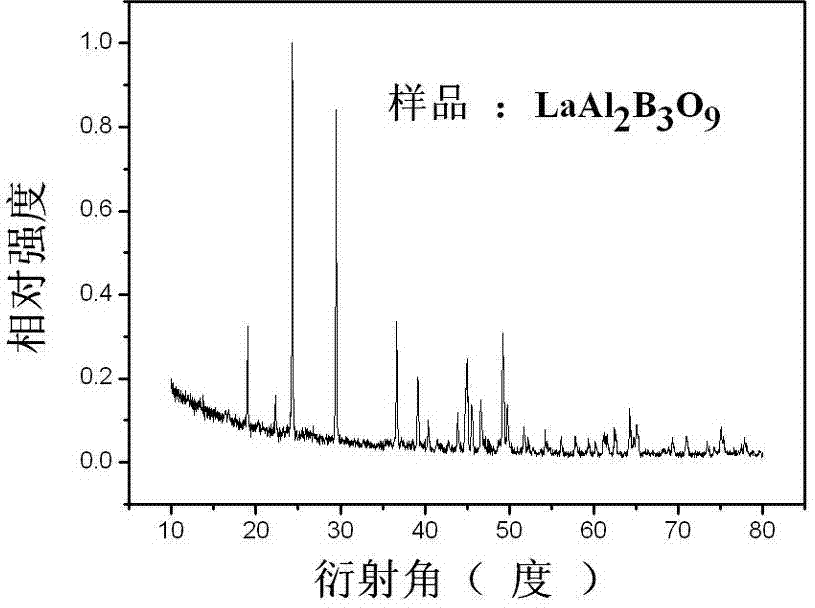

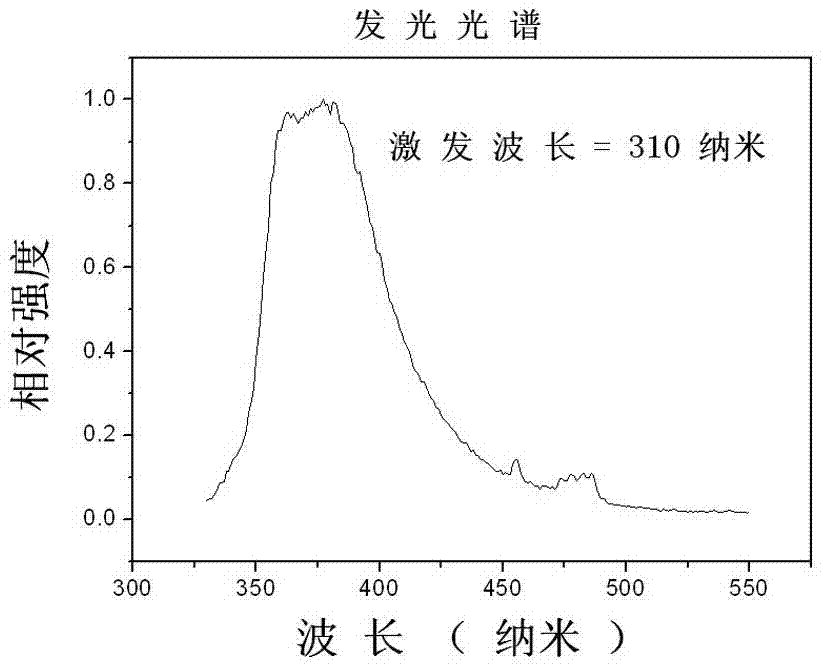

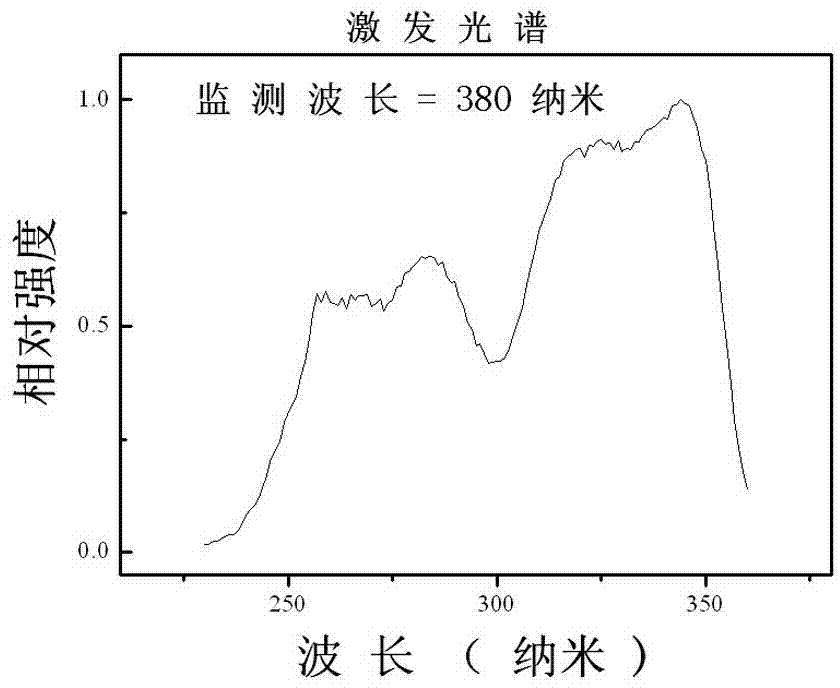

[0026] Preparation of La 0.995 Ce 0.005 al 2 B 3 o 9

[0027] According to the chemical formula La 0.995 Ce 0.005 al 2 B 3 o 9 The stoichiometric ratio of each element in the aluminum oxide Al 2 o 3 : 1.020 g, boric acid H 3 BO 3 : 1.855 g, lanthanum oxide La2 o 3 : 1.621 g, cerium oxide CeO 2 : 0.009 g, after being ground and mixed in an agate mortar, select the air atmosphere for the first calcination, the temperature is 200 ° C, the calcination time is 10 hours, then cooled to room temperature, and the sample is taken out; the raw material calcined for the first time is fully Mix and grind evenly, sinter again in air atmosphere, temperature 800°C, calcination time 4 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in a muffle furnace for sintering in a reducing atmosphere (buried in activated carbon powder ), the calcining temperature is 1000° C., and the calcining time is 4 hours, that is, a powdery boroa...

Embodiment 2

[0032] Preparation of La 0.99 Ce 0.01 al 2 B 3 o 9

[0033] According to the chemical formula La 0.99 Ce 0.01 al 2 B 3 o 9 The stoichiometric ratio of each element is weighed aluminum hydroxide Al(OH) 3 : 1.560 g, boric acid H 3 BO 3 : 1.855 grams, lanthanum nitrate La (NO 3 ) 3 : 3.217 g, cerium oxide CeO 2 : 0.018 g, after grinding and mixing in an agate mortar, select the air atmosphere for the first calcination, the temperature is 400 ° C, the calcination time is 3 hours, then cool to room temperature, take out the sample; the raw material for the first calcination is fully Mix and grind evenly, sinter again in air atmosphere, temperature 600°C, calcination time 9 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in a muffle furnace for sintering in a reducing atmosphere (buried in activated carbon powder ), the calcination temperature is 800° C., and the calcination time is 10 hours, and the powdery boroa...

Embodiment 3

[0035] Preparation of La 0.97 Ce 0.03 al 2 B 3 o 9

[0036] According to the chemical formula La 0.97 Ce 0.03 al 2 B 3 o 9 The stoichiometric ratio of each element in the aluminum oxide Al 2 o 3 : 1.020 g, boron oxide B 2 o 3 : 1.045 g, lanthanum oxide La 2 o 3 : 1.581 g, cerium oxide CeO 2 : 0.052 g, ground in an agate mortar and mixed evenly, select the air atmosphere for the first calcination, the temperature is 300 ℃, the calcination time is 7 hours, then cool to room temperature, take out the sample; the raw material calcined for the first time is fully Mix and grind evenly, sinter again in air atmosphere, temperature 700 ° C, calcination time 8 hours, then cool to room temperature, take out the sample; finally it is fully ground again and placed in a muffle furnace for sintering in a reducing atmosphere (buried in activated carbon powder ), the calcination temperature is 900° C., and the calcination time is 8 hours, and the powdery boroaluminate-based blu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com