Preparation method for ZIFs membrane containing zinc adopting sandwich structure and supported by high temperature resistant zinc oxide nanorod

A technology of zinc oxide nanorods and organic frameworks, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc. Weak carrier force and other issues, to achieve good change elasticity and operation and high temperature stability, high stability, mild condition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) The porous carrier is α-Al with an average pore diameter of about 0.1 μm 2 o 3 ceramic carrier tube. Before the synthesis, the carrier is first subjected to ultrasonic vibration treatment, then the carrier is cleaned with deionized water, and dried for later use.

[0028] (2) A certain amount of zinc acetate was dissolved in ethylene glycol methyl ether solvent and ethanolamine was used as a stabilizer to obtain a sol with a mass fraction of zinc of 12 wt%. Then the porous carrier was dipped and pulled to coat the pre-configured zinc sol, dried at 100°C for 2 hours, and repeated twice. Roast at 400°C for 2h, and set the heating rate at 1°C / min;

[0029] (3) Put the carrier tube with nano-zinc oxide seed crystals into a hydrothermal kettle containing a synthetic solution of 0.1M zinc nitrate hexahydrate and 0.1M hexamethylenetetramine and react at 100°C for 3h to obtain rod-shaped oxide Alumina ceramic tube with zinc rods.

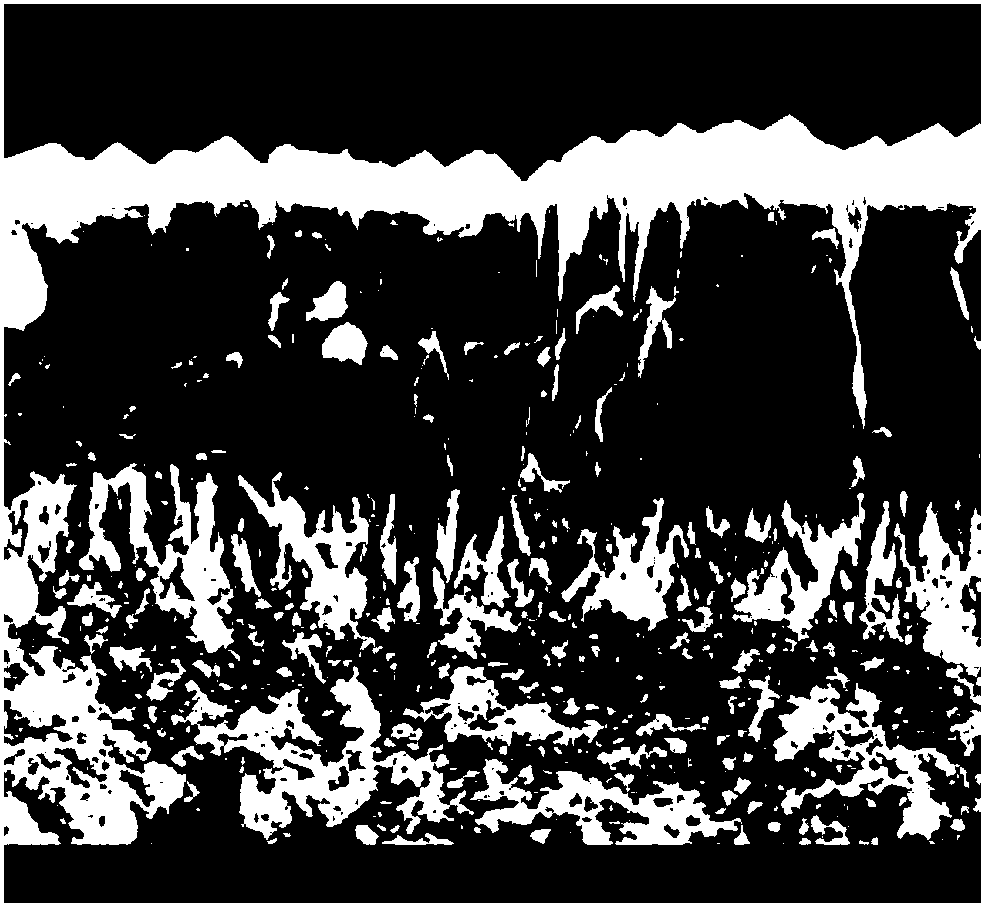

[0030] (4) Put the porous ceramic tub...

Embodiment 2

[0033] (1)~(3) are the same as Example 1;

[0034] (4) Put the porous ceramic tube with rod-shaped zinc oxide into the prepared 0.5M 2-methylimidazole ethanol activation solution for activation at 50°C for 10 minutes, take it out and dry it in the air;

[0035] (5) After activation, the porous ceramic tube of rod-shaped zinc oxide is placed in a ratio of HCOONa:ZnCl 2 :2-meIM:MeOH=1.5:1.0:1.5:900 film synthesis solution, grow film at 100℃ for 5h. Cool the reaction kettle to room temperature naturally, take out the ceramic tube, slowly rinse the surface of the film layer to remove the crystals attached to the surface layer, dry it naturally and place it in a desiccator for testing.

Embodiment 3

[0037] (1)~(3) are the same as Example 1;

[0038] (4) Put the porous ceramic tube with rod-shaped zinc oxide into the prepared 0.5M 2-methylimidazole water activation solution for activation at 50°C for 0.5h, take it out and dry it in the air;

[0039] (5) After activation, the porous ceramic tube of rod-shaped zinc oxide is placed in a ratio of HCOONa:ZnCl 2:2-meIM:MeOH=1.5:1.0:1.5:900 film synthesis solution, grow film at 100℃ for 2h. Cool the reaction kettle to room temperature naturally, take out the ceramic tube, slowly rinse the surface of the film layer to remove the crystals attached to the surface layer, dry it naturally and place it in a desiccator for testing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com