Preparation method of response-temperature-adjustable temperature sensitive hydrogel

A temperature-sensitive hydrogel and hydrogel technology, which is applied in the field of temperature-sensitive hydrogel preparation, can solve the problems of complex synthesis method and insignificant temperature response behavior of hydrogel, and achieve excellent mechanical properties, accurate and reliable performance. The effect of adjusting the response temperature and the uniformity of the three-dimensional network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

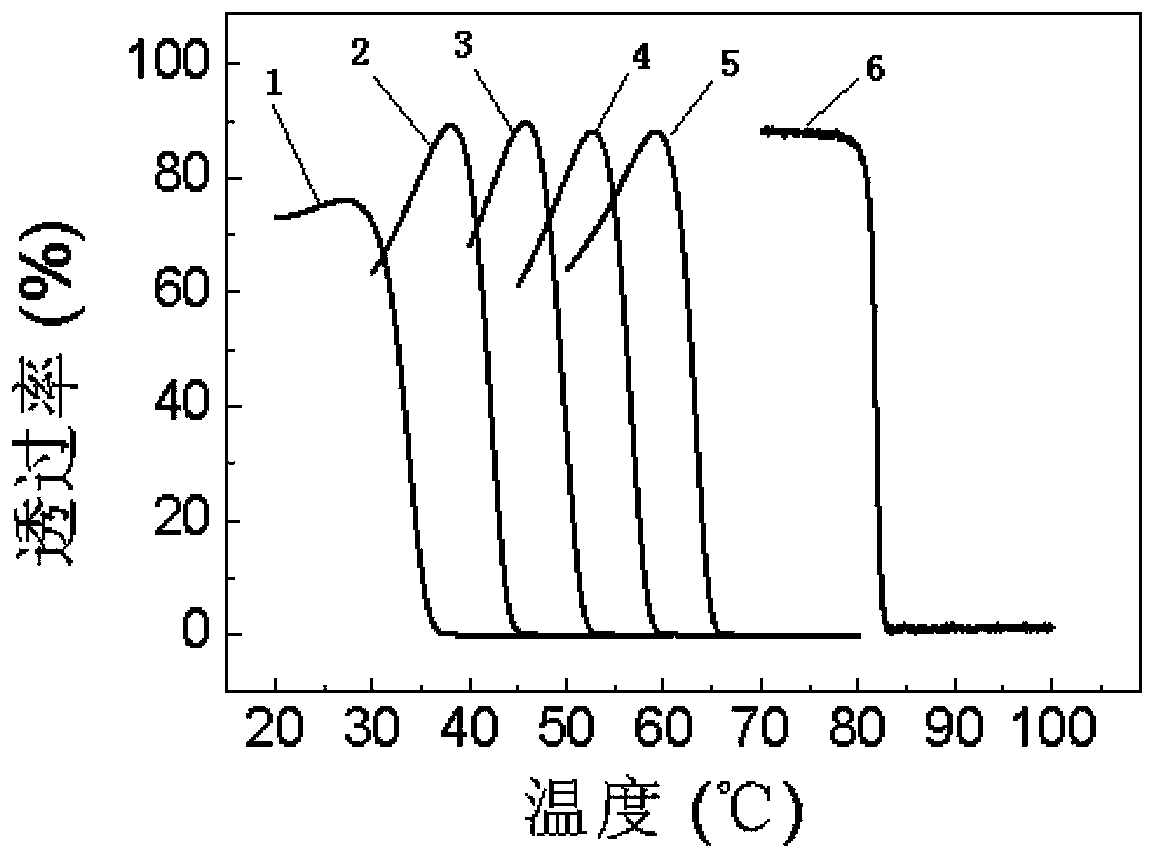

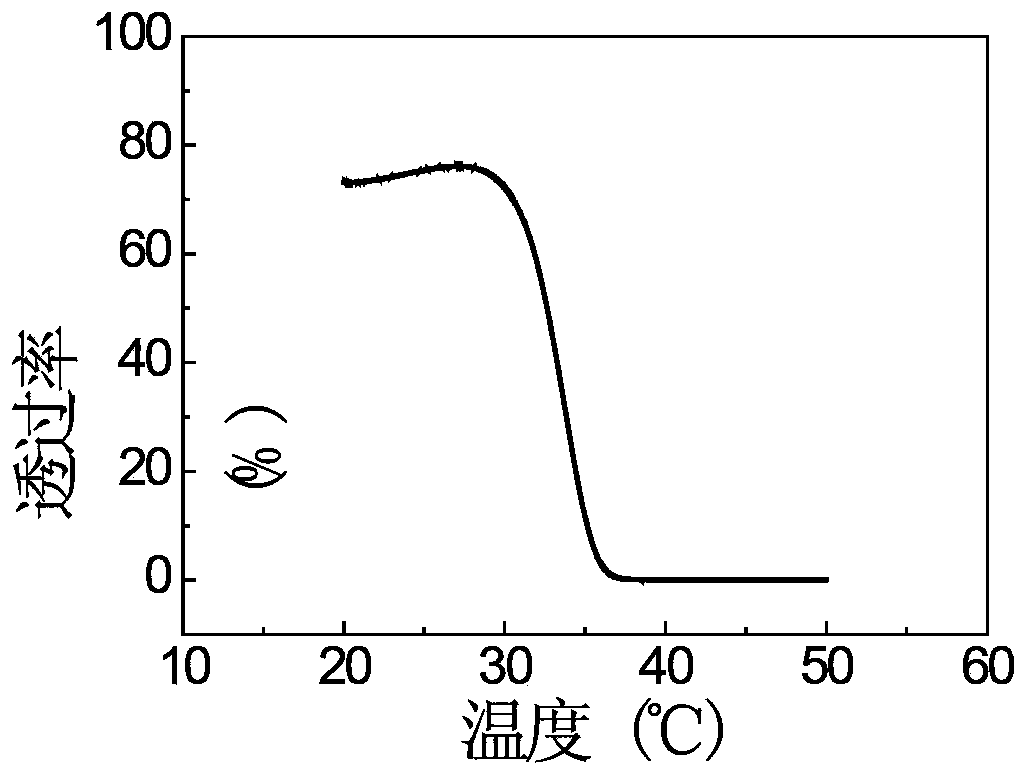

[0026] Add 1.562g 2-methyl-2-acrylic acid-2-(2-methoxyethoxy) ethyl ester, 0.438g oligoethylene glycol methyl ether methacrylate, 0.5g commercially available inorganic clay Laponite in 10g water XLS, 0.02g potassium persulfate, 0.01g N,N,N',N'-tetramethylethylenediamine to obtain a transparent hydrogel prepolymer; transfer the hydrogel prepolymer to a quartz with an optical path length of 10mm In a cuvette, react at 20°C for 24 hours to obtain a temperature-sensitive hydrogel. The result is as follows:

[0027] The response temperature of the hydrogel is 27.6°C, and the light transmittance changes with temperature as follows: figure 2 shown.

Embodiment 2

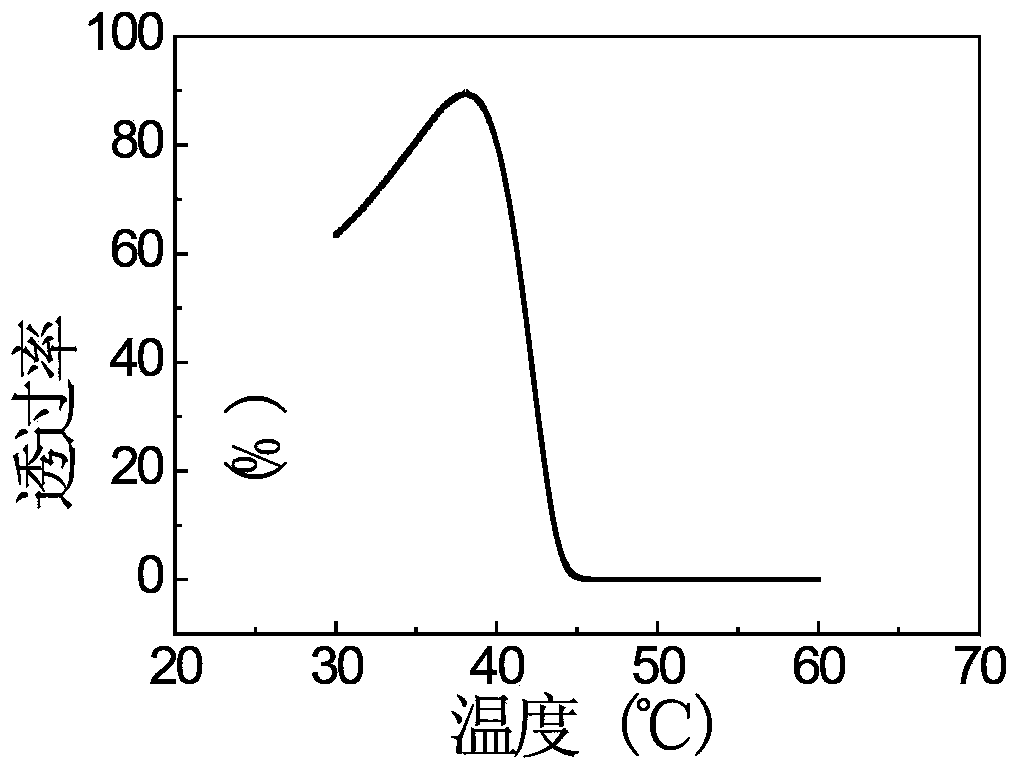

[0029] Add 1.226g 2-methyl-2-acrylic acid-2-(2-methoxyethoxy) ethyl ester, 0.774g oligoethylene glycol methyl ether methacrylate, 0.5g commercially available inorganic clay Laponite to 10g water XLS, 0.02g potassium persulfate, 0.01g N,N,N',N'-tetramethylethylenediamine to obtain a transparent hydrogel prepolymer; transfer the hydrogel prepolymer to a quartz with an optical path length of 10mm In a cuvette, react at 20°C for 24 hours to obtain a temperature-sensitive hydrogel. The result is as follows:

[0030] The response temperature of the hydrogel is 38.1°C, and the light transmittance changes with temperature as follows: image 3 shown.

Embodiment 3

[0032] Add 0.960g 2-methyl-2-acrylic acid-2-(2-methoxyethoxy) ethyl ester, 1.040g oligoethylene glycol methyl ether methacrylate, 0.5g commercially available inorganic clay Laponite in 10g water XLS, 0.02g potassium persulfate, 0.01g N,N,N',N'-tetramethylethylenediamine to obtain a transparent hydrogel prepolymer; transfer the hydrogel prepolymer to a quartz with an optical path length of 10mm In a cuvette, react at 20°C for 24 hours to obtain a temperature-sensitive hydrogel. The result is as follows:

[0033] The response temperature of the hydrogel is 45.7°C, and the light transmittance changes with temperature as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com