Halogen-free sheet-like soft magnetic material adhesive, preparation method and halogen-free soft magnetic sheet

A technology of soft magnetic materials and adhesives, applied in the direction of inorganic material magnetism, adhesives, non-polymer adhesive additives, etc., to achieve strong magnetic properties, good economic and social benefits, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

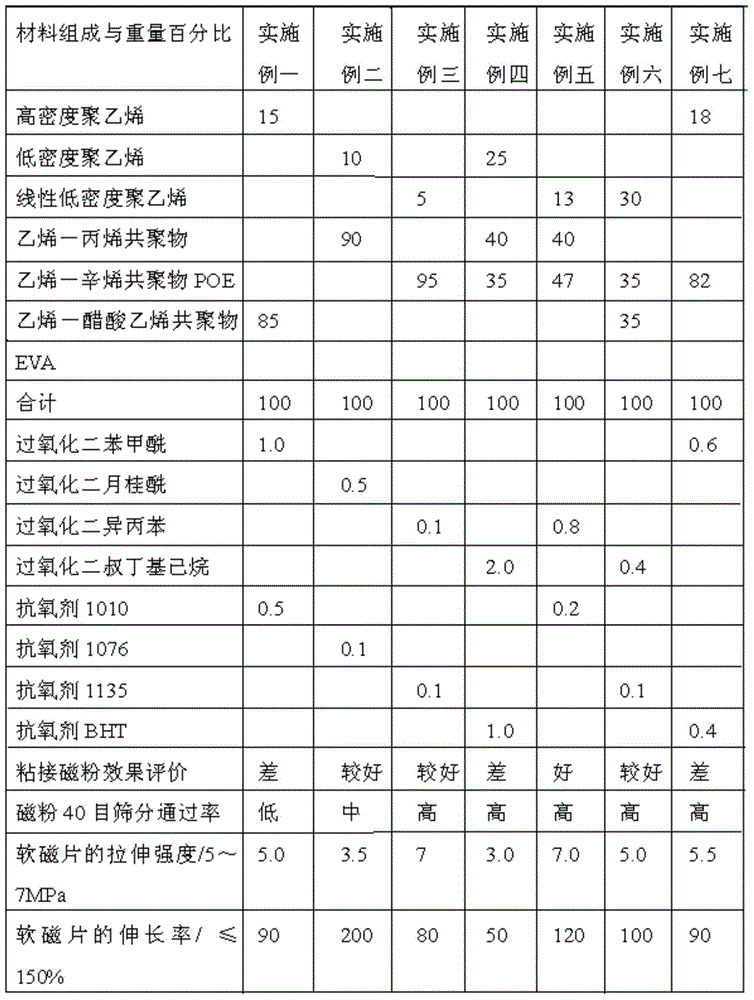

[0020] The material components and the proportioning ratio of a kind of halogen-free flake soft magnetic material adhesive of the present invention are:

[0021] 5~30wt.% polyethylene, 70~95wt.% polyolefin copolymer, 0.1~2.0wt.% crosslinking agent, 0.1~1.0wt.% antioxidant.

[0022] The preferred material composition and ratio are: polyethylene 5-25wt.%, polyolefin copolymer 72-90wt.%, crosslinking agent 0.2-1.0wt.%, antioxidant 0.1-0.5wt.%.

[0023] Described polyethylene is high-density polyethylene, low-density polyethylene, linear low-density polyethylene.

[0024] The polyolefin copolymer is one or two of ethylene-propylene copolymer, ethylene-octene copolymer and ethylene-vinyl acetate copolymer.

[0025] The crosslinking agent is one of dibenzoyl peroxide, dilauroyl peroxide, dicumyl peroxide and di-tert-butyl hexane peroxide.

[0026] Described antioxidant is a kind of in 1010,1076,1135, BHT antioxidant.

[0027] The preparation method steps of the halogen-free flake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com