Oxide sintered compact and sputtering target

一种氧化物、烧结体的技术,应用在溅射镀覆、半导体/固态器件制造、离子注入镀覆等方向,能够解决不均匀、电阻率高等问题,达到生产率提高、削减原料成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

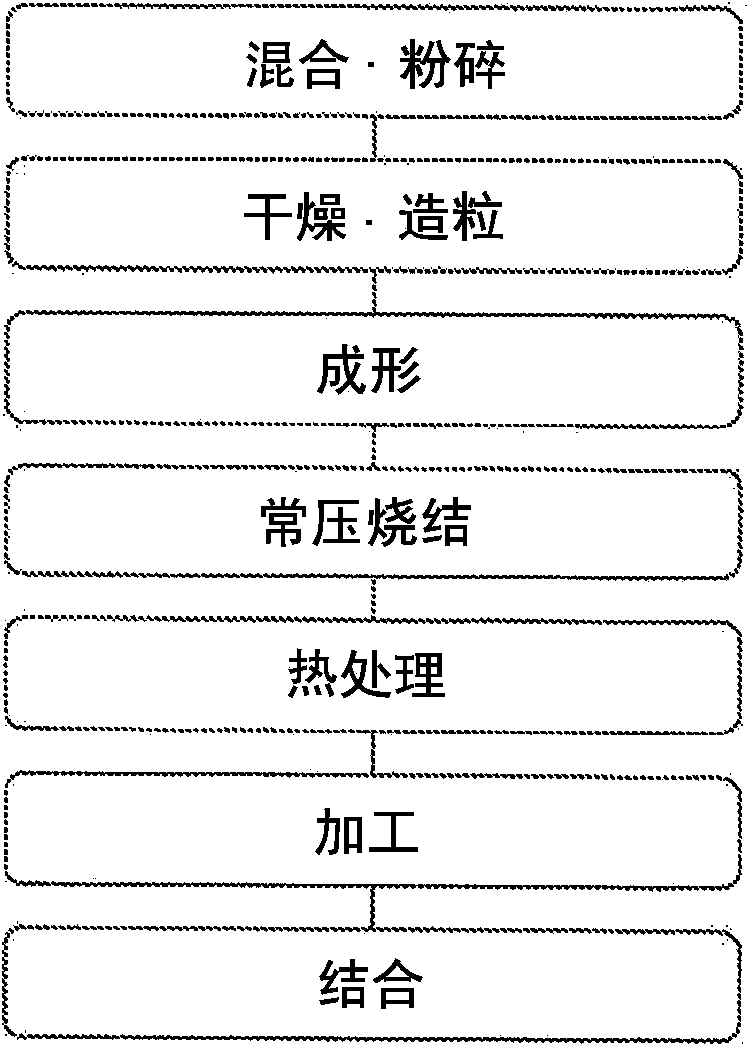

[0074] Zinc oxide powder (JIS 1 type) with a purity of 99.99%, tin oxide powder with a purity of 99.99%, and alumina powder with a purity of 99.99% are blended at a ratio of [Zn]:[Sn]:[Al]=73.9:24.6:1.5, Mix with a nylon ball mill for 20 hours. The Zn ratio and the Sn ratio are shown in Table 1 for reference. The Al ratio was 0.015. Next, the mixed powder obtained in the above process is dried and granulated, and pressed with a mold at a molding pressure of 0.5 tonf / cm 2 After preforming, use CIP with a forming pressure of 3tonf / cm 2 Do the main shaping.

[0075] The compacts thus obtained were held at 1500° C. for 7 hours under normal pressure as shown in Table 1, and sintered. Oxygen is introduced into the sintering furnace, and sintering is carried out in an oxygen environment. Next, it was introduced into a heat treatment furnace, and heat treatment was performed at 1200° C. for 10 hours. Nitrogen gas is introduced into the heat treatment furnace, and heat treatment ...

experiment example 2

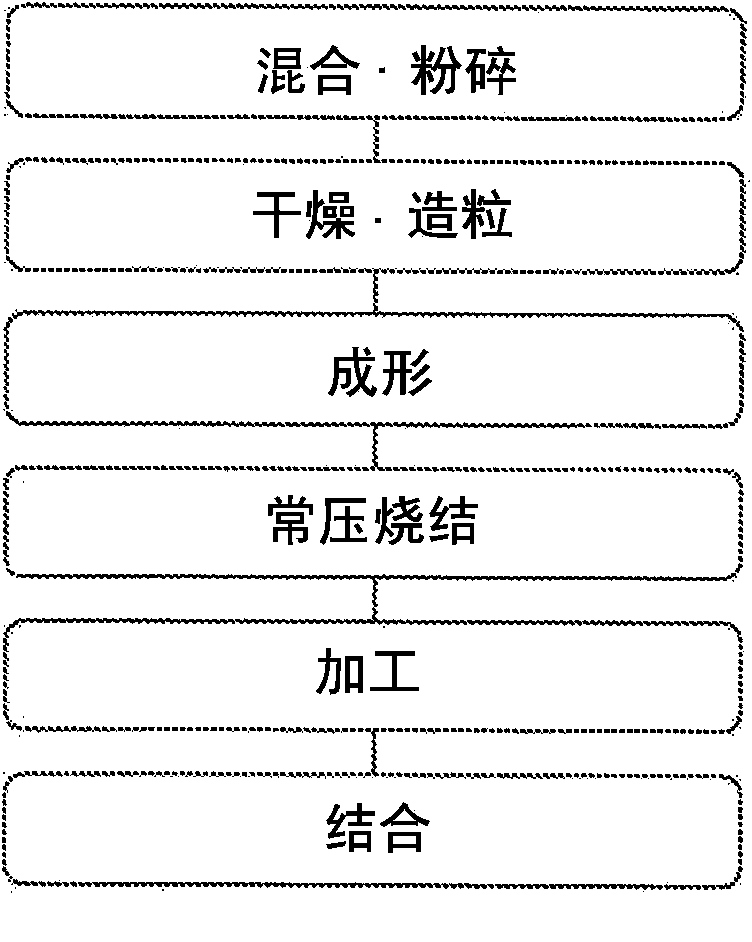

[0081] Zinc oxide powder (JIS 1 type) with a purity of 99.99%, tin oxide powder with a purity of 99.99%, and tantalum oxide powder with a purity of 99.99% are mixed in a ratio of [Zn]:[Sn]:[Ta]=73.9:24.6:1.5, After sintering at 1550° C. for 5 hours, heat treatment was performed at 1150° C. for 14 hours, and the oxide sintered body of Experimental Example 2 (Ta ratio = 0.015) was obtained in the same manner as in Experimental Example 1 above.

[0082] The relative density and resistivity of the oxide sintered body of Experimental Example 2 obtained in this way were measured in the same manner as in Experimental Example 1 above. As a result, the relative density was 90% or more and the resistivity was 0.10Ω·cm or less, which were good results.

[0083] Next, DC (direct current) magnetron sputtering was performed on the above-mentioned oxide sintered body in the same manner as in the above-mentioned Experimental Example 1. As a result, no abnormal discharge (arc) was observed, and...

experiment example 3

[0087] Zinc oxide powder (JIS 1 type) with a purity of 99.99%, tin oxide powder with a purity of 99.99%, and indium oxide powder with a purity of 99.99% are mixed at a ratio of [Zn]:[Sn]:[In]=45.0:45.0:10.0, The oxide sintered body of Experimental Example 3 (In ratio = 0.10) was obtained in the same manner as in Experimental Example 1 above except that it was sintered at 1550° C. for 5 hours (without heat treatment).

[0088] The relative density and resistivity of the oxide sintered body of Experimental Example 3 thus obtained were measured in the same manner as in Experimental Example 1 above. As a result, good results were obtained with a relative density of 90% or more and a resistivity of 0.10Ω·cm or less.

[0089] Next, DC (direct current) magnetron sputtering was performed on the above-mentioned oxide sintered body in the same manner as in the above-mentioned Experimental Example 1. As a result, no abnormal discharge (arc) was observed, and stable discharge was confirmed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com