Nutrient grain jelly and manufacturing method thereof

A technology of grain freezing and nutrition, which is applied in the field of food processing and can solve problems such as single nutrition, low nutritional value, and insufficient nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

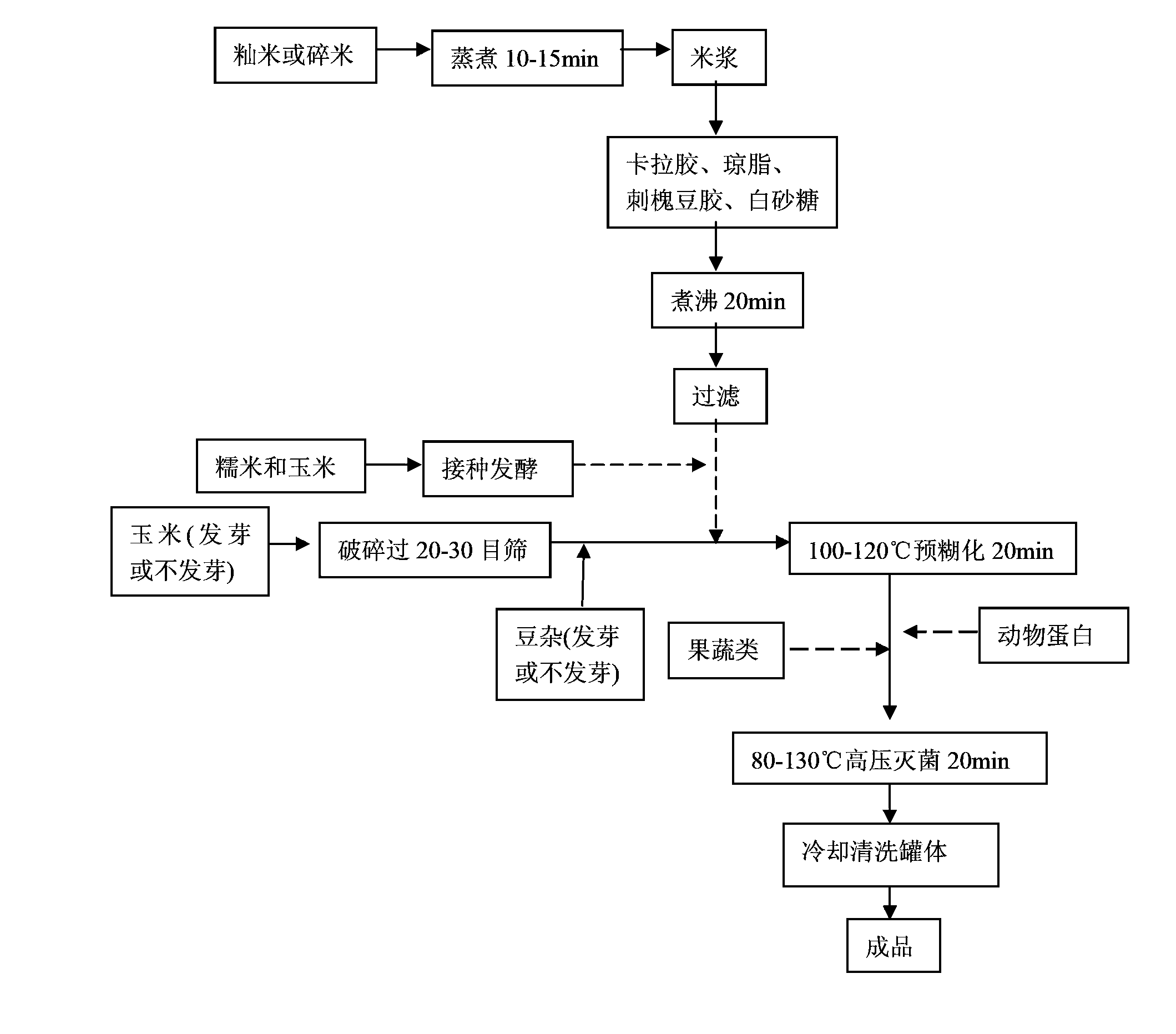

Method used

Image

Examples

Embodiment 1

[0172] Embodiment 1: the determination of mixed glue process

[0173] In order to make the product in good condition, coagulation, elasticity, brittleness and production cost should be considered comprehensively. Carrageenan, agar and locust bean gum were selected as experimental raw materials, and L9(3 4 ) designed an orthogonal experiment design, the mixed glue obtained in the test process was used to make corn jelly, and the optimal proportioning scheme of the mixed glue was screened. The sensory evaluation table is shown in Table 1, and the sensory evaluation standard is shown in Table 3.

[0174] Table 1 Sensory evaluation table of corn jelly with different mixing ratios

[0175]

[0176] It can be seen from Table 1 that the effect of carrageenan, agar and locust bean gum on the sensory quality of corn jelly is agar > carrageenan > locust bean gum. In formulas No. 3, 5 and 9, the sensory evaluation of corn jelly reached the highest Good, but due to the different rati...

Embodiment 2

[0177] Embodiment 2: Nutrition change experiment in raw material germination

[0178]Take clean raw materials (corn or miscellaneous beans), soak mung beans in clean water with a volume ratio of 2:1~4:1 for raw materials for 4-6 hours, put the soaked raw materials into 1g / L hypochlorite Germinate in a germination machine (CB-A33, Kornit) sterilized with calcium acid acid, and the raw materials are changed (or added) with clean water every 12 hours during the germination process. After the raw materials are germinated, the changes of their main nutritional indicators are detected, as shown in Table 2.

[0179] Table 2 Variations of main nutrients in different raw materials during germination

[0180]

[0181] It can be seen from Table 3 that the contents of the main nutritional components of several raw materials after slight germination have the same trend of change. In the early stage of germination, the water-absorbing swelling of raw seeds stimulates the activity of in...

Embodiment 3

[0182] Example 3: Corn nutritional jelly

[0183] Step 1: Take 10 kg of clean corn (germinated or not), crush, peel, and pass through a 40-20 mesh sieve to obtain 6 kg of corn grits, and obtain material 1.

[0184] Step 2: Weigh 7.2 kg of white sugar, 0.36 kg of carrageenan, 0.72 kg of agar, and 0.36 kg of locust bean gum, mix well and add 120 kg of water, heat to boil, and keep stirring until the materials are completely dissolved after 10-20 minutes. The material is filtered with gauze to obtain the material 2.

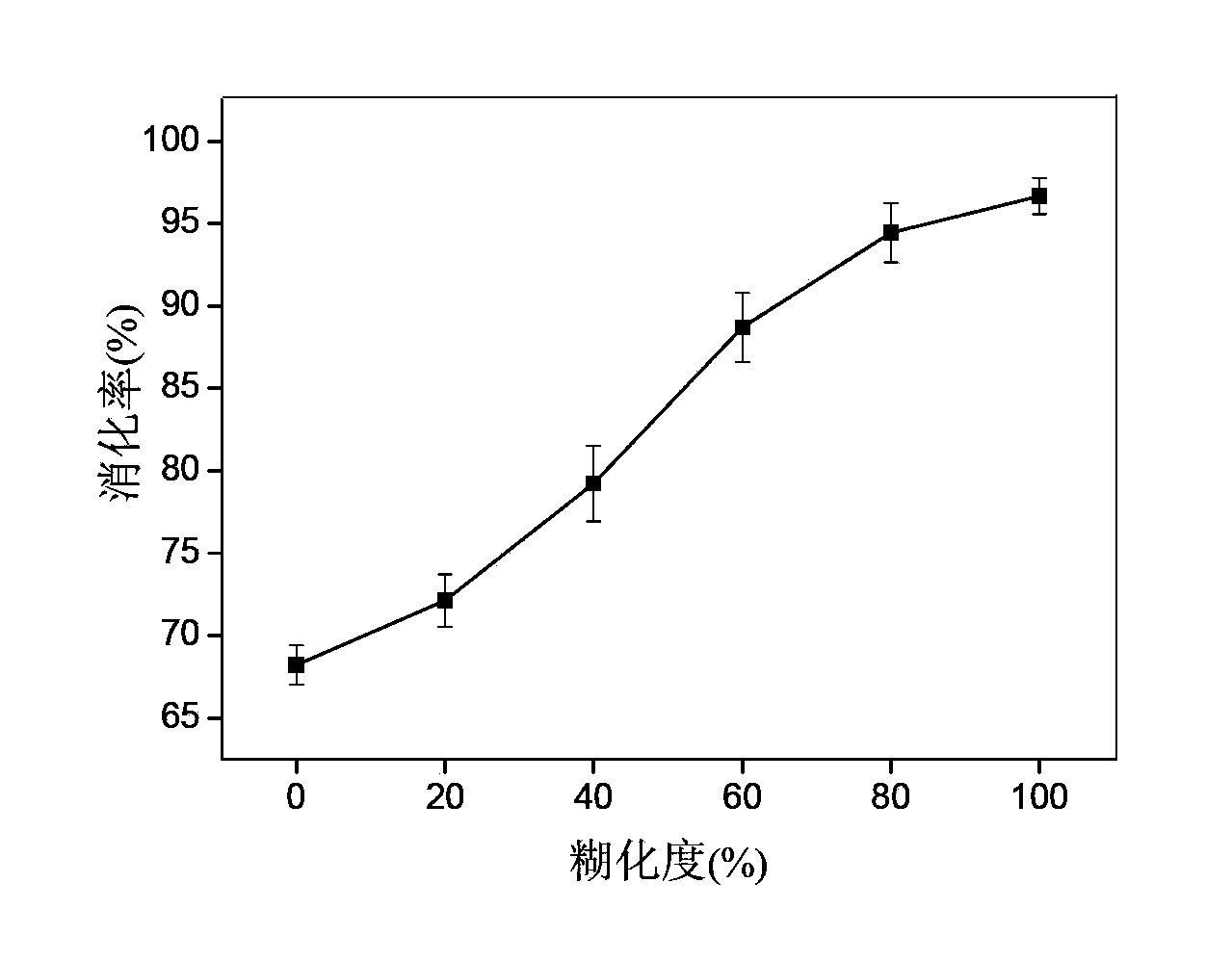

[0185] Step 3: Mix the material obtained in step 2 with the cleaned material 1, and cook in a pressure cooker at 105°C for 20 minutes to partially gelatinize the starch inside the corn and emit the unique aroma of corn.

[0186] Step 4: Hot-fill the materials obtained in Step 3, sterilize at 121°C for 20 minutes, and cool to obtain the finished nutritional corn jelly. After evaluation, the product is novel in style, soft in taste and long in aftertaste.

[0187] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com