Ketoprofen lansoprazole sustained-release pellets, as well as preparation method and preparation thereof

A technology for sustained-release pellets and lansoprazole, applied in the directions of anti-inflammatory agents, pharmaceutical formulations, non-central pain relievers, etc., to achieve the effects of increasing stability, good roundness and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the preparation of ketoprofensoprazole sustained-release pellets

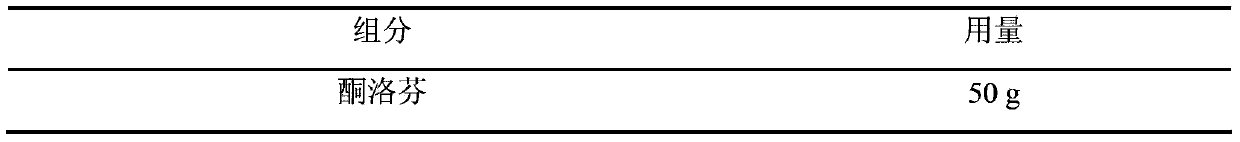

[0023] prescription

[0024]

[0025]

[0026] method Ketoprofen, lansoprazole, microcrystalline cellulose, polyethylene glycol 6000 and ethyl cellulose are pulverized into fine powders with a fineness of more than 100 mesh respectively; , microcrystalline cellulose, polyethylene glycol 6000 and ethyl cellulose, mix evenly, add water to make a soft material, put it in an extrusion spheronizer, set the extrusion sieve to 1.0mm, and the extrusion speed to 90r / min 1. The spheronization speed is 480r / min, the spheronization time is 8min, and the pellets are made, dried at 40°C, sieved, and the pellets with a particle size of 20-24 meshes are collected to obtain the product.

[0027] quality The yield of pellets with a particle size of 20-24 mesh is 95%; the pellets have good roundness and smooth surface, and the in vitro release rates at 1, 4, 8, 12, and 16 hours are 7.6, 18.6, 37...

Embodiment 2

[0028] Embodiment 2, the preparation of ketoprofensoprazole sustained-release pellets

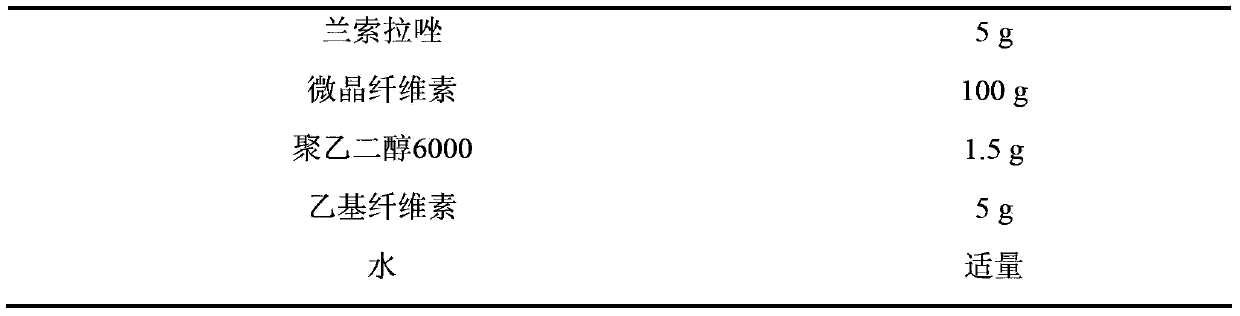

[0029] prescription

[0030]

[0031] method Ketoprofen, lansoprazole, microcrystalline cellulose, lactose, magnesium stearate, talcum powder and ethyl cellulose are pulverized into the fine powder that fineness is above 100 mesh respectively; Get the ketoprofen of prescription quantity, Lansoprazole, microcrystalline cellulose, lactose, magnesium stearate, talcum powder and ethyl cellulose, mixed evenly, adding povidone K30 ethanol solution with a mass fraction of 2% to make a soft material, extruding and rolling In the machine, set the extrusion sieve hole to 1.0mm, the extrusion speed to 100r / min, the spheronization speed to 500r / min, and the spheronization time to 6min to make pellets, dry at 35-45°C, sieve, and collect for 20-20 Micropellets with a particle size of 24 meshes are available.

[0032] quality The yield of pellets with a particle size of 20-24 mesh was 89%; the...

Embodiment 3

[0033] Embodiment 3, the preparation of ketoprofensoprazole sustained-release pellets

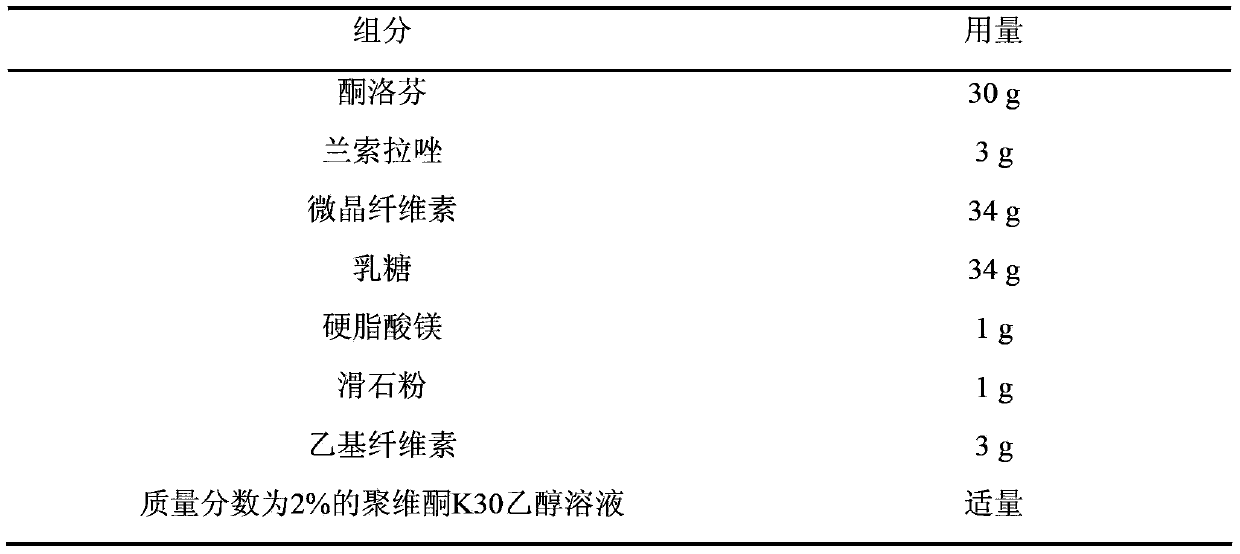

[0034]prescription

[0035]

[0036] method Ketoprofen, lansoprazole, microcrystalline cellulose, lactose and ethyl cellulose are respectively pulverized into fine powders with a fineness of more than 100 mesh; , lactose and ethyl cellulose, mix evenly, add ethanol with a volume fraction of 45% to make a soft material, put it in an extrusion spheronizer, set the extrusion sieve to 1.0mm, the extrusion speed to 110r / min, and spheronize The rotation speed is 460r / min, the spheronization time is 5min, and the pellets are made, dried at 45°C, sieved, and pellets with a particle size of 20-24 meshes are collected to obtain the product.

[0037] quality The yield of pellets with a particle size of 20-24 mesh was 87%. The pellets had good roundness and smooth surface. 79.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com