Nano-cluster assembled microporous-mesoporous composite molecular sieve and synthetic method thereof

A composite molecular sieve and synthesis method technology, applied in the field of molecular sieves and their preparation, can solve the problems of lower production costs, poor thermal and hydrothermal stability, and restricted applications, and achieve the effects of simple preparation methods, broad application prospects, and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

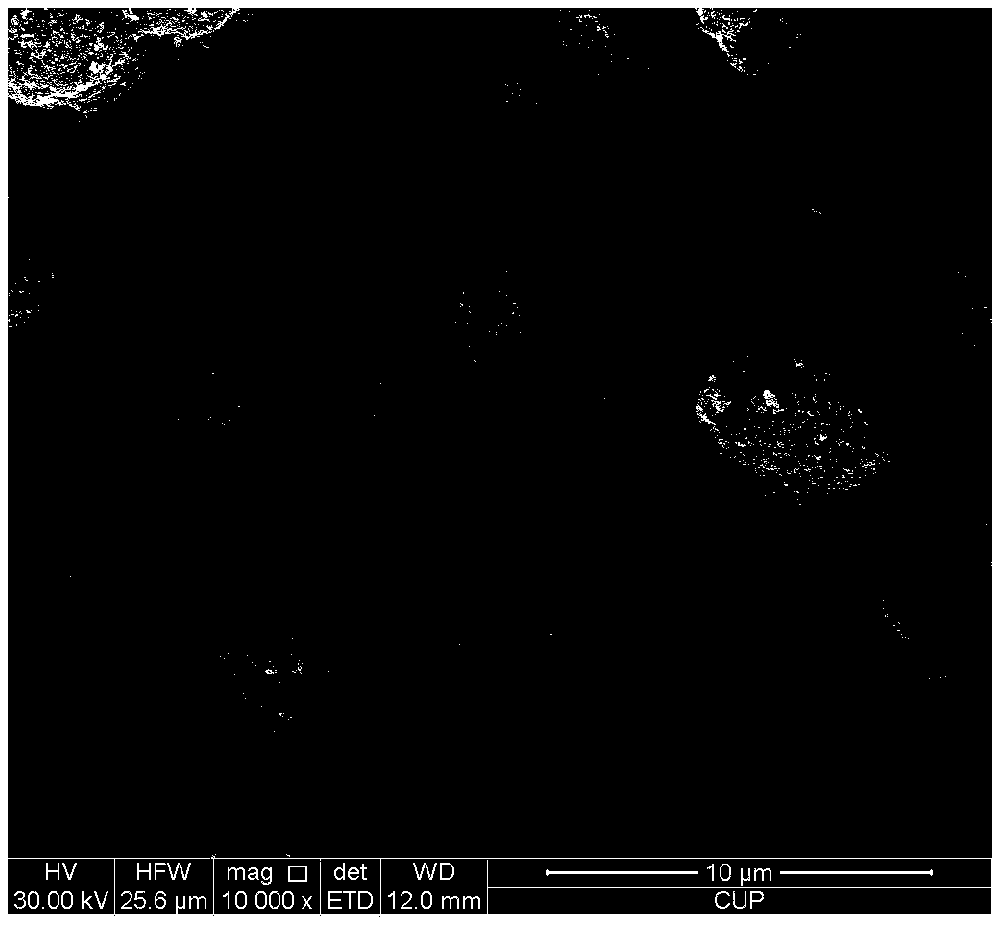

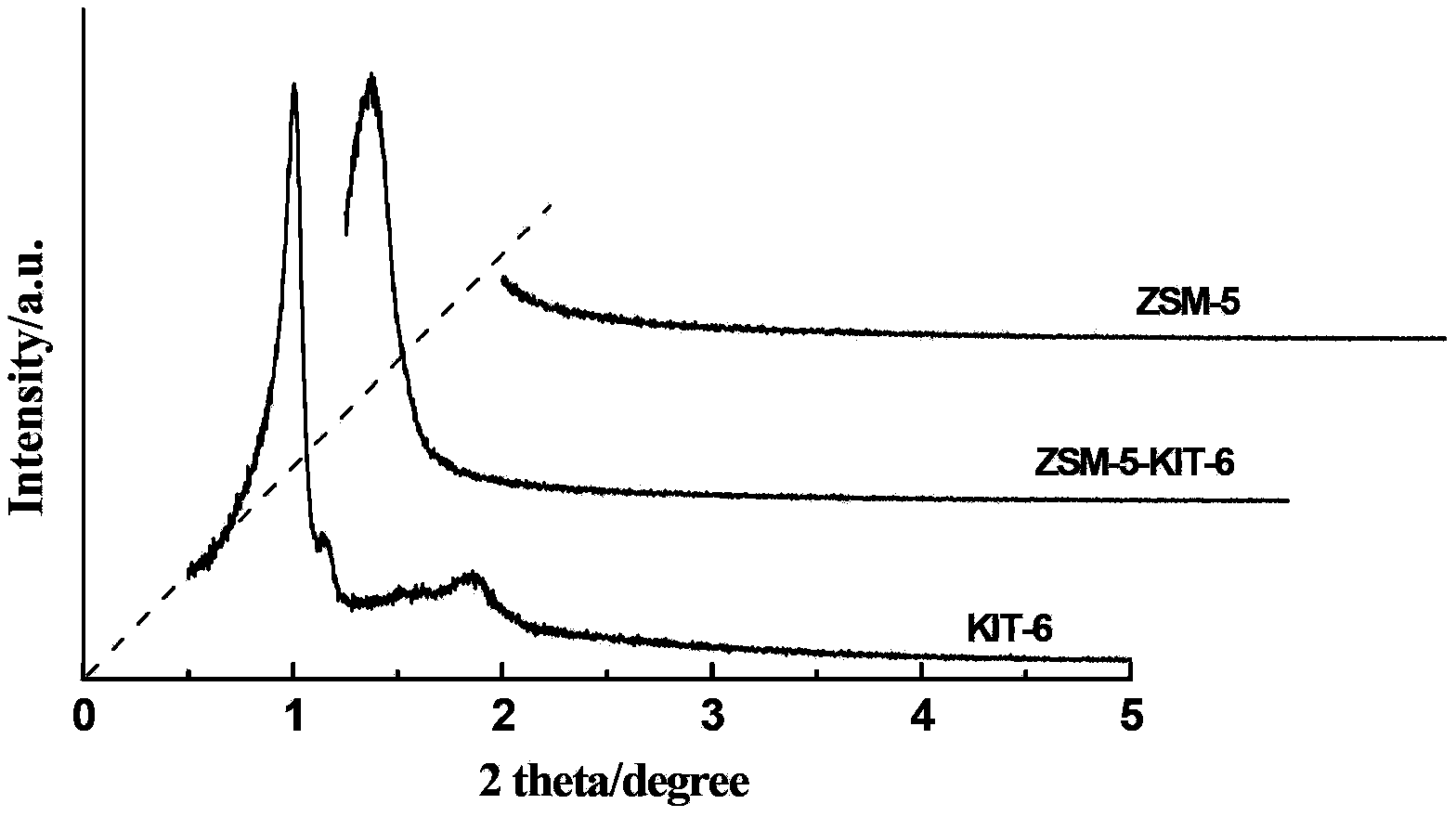

[0030] Dissolve 0.24g of solid sodium hydroxide with 14.95g of deionized water, then add 0.26g of sodium metaaluminate and 2.12g of TPABr into the lye, stir well, then add 9.36g of silica sol (in the form of SiO 2 Then add 0.135g of Trixton X-100, stir the mixture at room temperature for 1.0h, and cultivate it at 140°C for 16h to obtain ZSM-5 molecular sieve nanocrystal clusters; figure 1 As shown, it can be seen from the figure that the ZSM-5 molecular sieve is spherical, and the particle size is about 5-6 μm.

[0031] Dissolve 2.71g of P123 in 17.53g of deionized water, stir in a constant temperature water bath at 35°C for 2h to make it a transparent colloidal solution; then add 5.80g of n-butanol (n-BuOH), and continue stirring for 1.0h to obtain a mesoporous template solution.

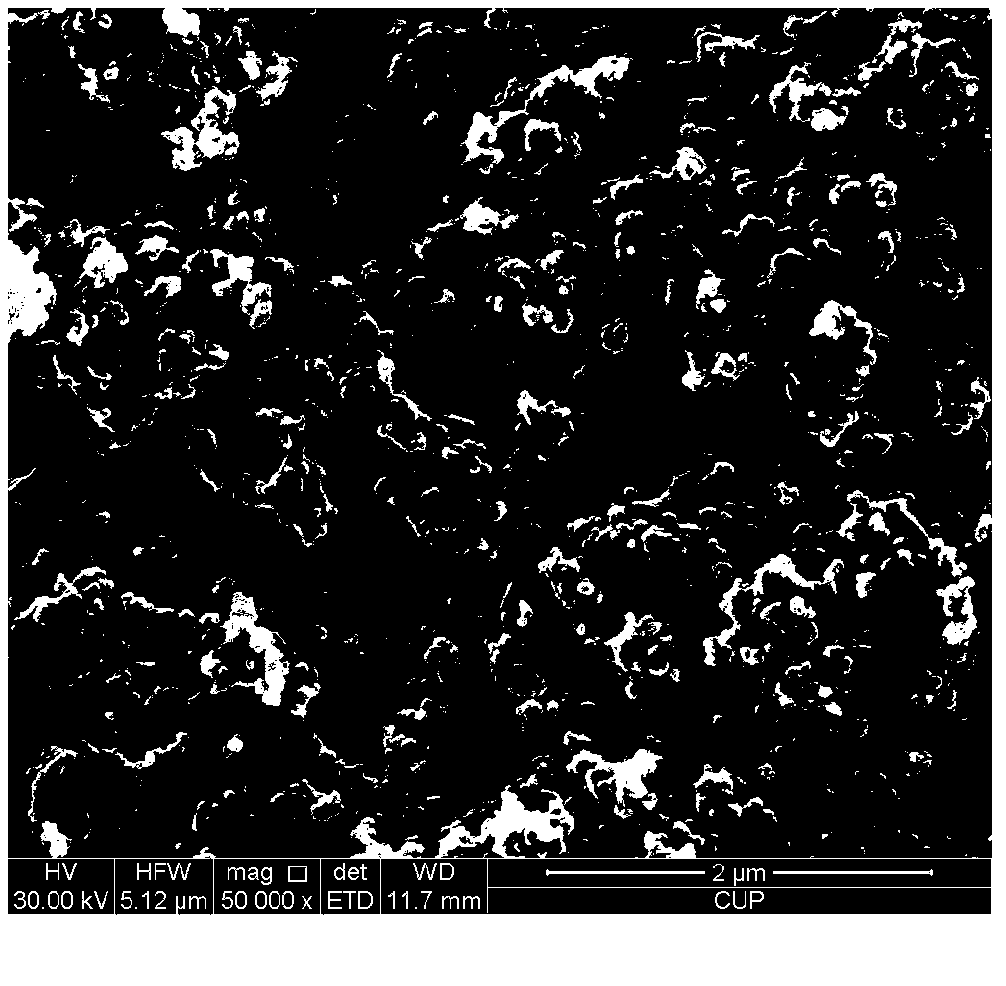

[0032] Slowly and evenly add the ZSM-5 nanocrystal clusters obtained in step 1 to the mesoporous template solution obtained above, and control the molar ratio of the materials to be Na 2 O: Al 2...

example 2

[0035] Dissolve 0.31g of solid sodium hydroxide with 16.66g of deionized water, then dissolve 0.49g of Al 2 (SO 4 ) 3 18H 2 O and 4.99g TPABr were added to the lye, and after stirring evenly, 7.65g tetraethyl orthosilicate TEOS (based on SiO 2 Add 0.60g of fatty alcohol polyoxyethylene ether AEO-9, stir the mixture at room temperature for 0.5h, and incubate at 170°C crystallization temperature for 2.0h to obtain ZSM-5 molecular sieve nanocrystal clusters, such as Further prolonging the crystallization time to 72h, can obtain as Figure 5 The ZSM-5 molecular sieve shown. from Figure 5 It can be seen that the ZSM-5 molecular sieve grain size is about 1.8 μm, and the distribution is relatively uniform.

[0036]Dissolve 12.78g of P123 in 14.72g of deionized water, stir in a constant temperature water bath at 35°C for 2.0h to make it a transparent colloidal solution; then add 4.38g of n-butanol (n-BuOH), and continue stirring for 1.0h to obtain a mesoporous template agent s...

example 3

[0040] 0.23g solid sodium hydroxide was dissolved with 12.53g deionized water, then 0.07g KAlO 2 And 3.06g TPABr joins in the lye, after stirring evenly, add 8.77g water glass (as SiO 2 Then add 0.25g of alkylphenol polyoxyethylene ether OP-10, stir the mixture at room temperature for 3.0h, and incubate at 150°C crystallization temperature for 10h to obtain ZSM-5 molecular sieve nanocrystal clusters.

[0041] Dissolve 9.80g of P123 in 18.19g of deionized water, stir in a constant temperature water bath at 35°C for 2.0h to make it a transparent colloidal solution; then add 5.03g of n-butanol (n-BuOH), and continue stirring for 1.0h to obtain a mesoporous template agent solution.

[0042] Slowly and evenly add the ZSM-5 nanocrystal clusters obtained in step 1 to the mesoporous template solution obtained above, and control the molar ratio of the materials to be Na 2 O: Al 2 o 3 : SiO 2 :TPABr:H 2 O: P123: n-butanol=2.5:0.3:35:10:2400:1.5:60 Add 12.32g of 20% hydrochloric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com