Hydrophilic magnetic resin with high specific surface area and preparation method thereof and method for rapidly extracting phthalic acid ester in water body

A high specific surface area, magnetic resin technology, applied in the direction of extraction water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of lack of detection methods and difficult detection of phthalates, and achieve improved Extraction efficiency, realize fast and efficient solid phase extraction and detection analysis, and enhance the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

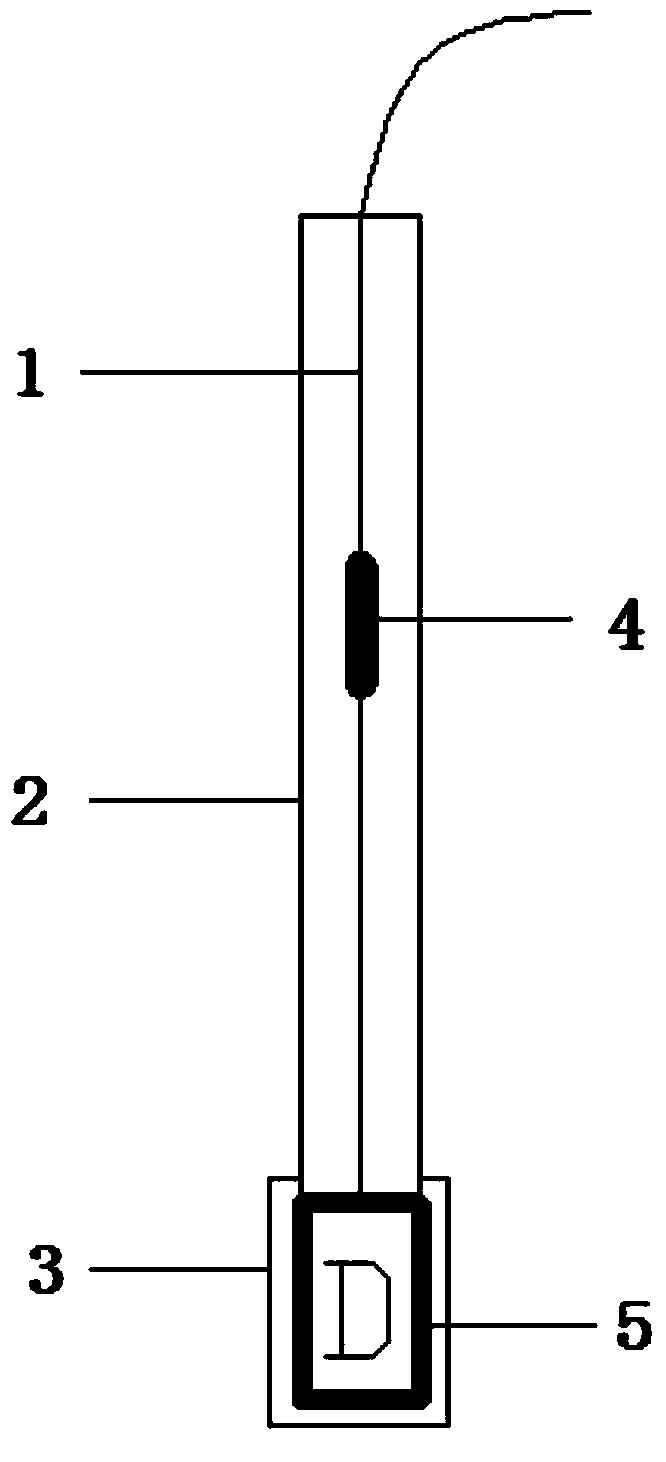

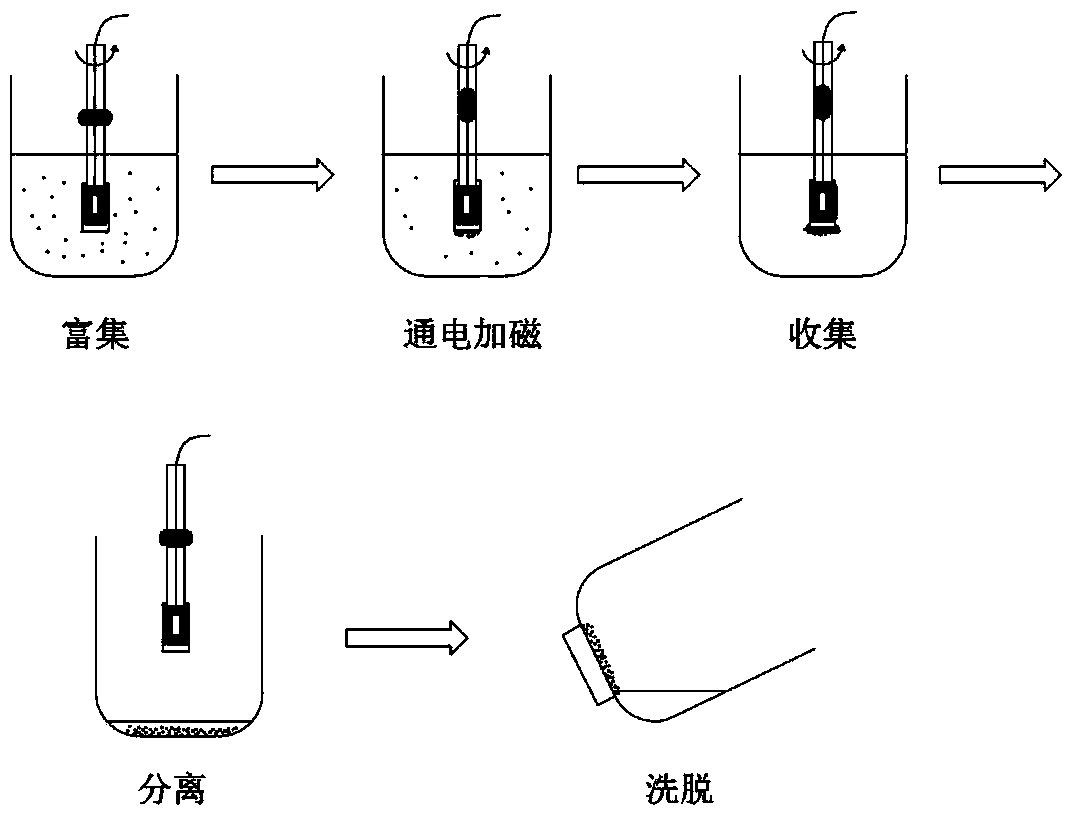

[0043] A preparation method of a hydrophilic high specific surface area magnetic resin, the steps of which are:

[0044] (a) Equipped with a water phase, in which 0.5% to 2% of gelatin and 5 to 20% of salt are added, accounting for the mass percentage of the water phase;

[0045] (b) Equipped with an oil phase, mix the reactant monomer and the porogen toluene, add the initiator benzoyl peroxide, and mix well to obtain the oil phase; the reactant monomers are divinylbenzene, vinyl benzoate and formaldehyde Glycidyl acrylate, wherein the mass ratio of vinyl benzoate to divinylbenzene is 1:0.5-2, and the mass ratio of glycidyl methacrylate to divinylbenzene is 1:1-9. The mass ratio of the porogen toluene to the reactant monomer is 1-2:1, and the mass ratio of the initiator benzoyl peroxide is 0.5-3% of the total amount of the reactant monomer and the porogen.

[0046] (c) Add oleic acid-coated and modified magnetic particles to the oil phase, and after mixing evenly, add the oil...

Embodiment 1

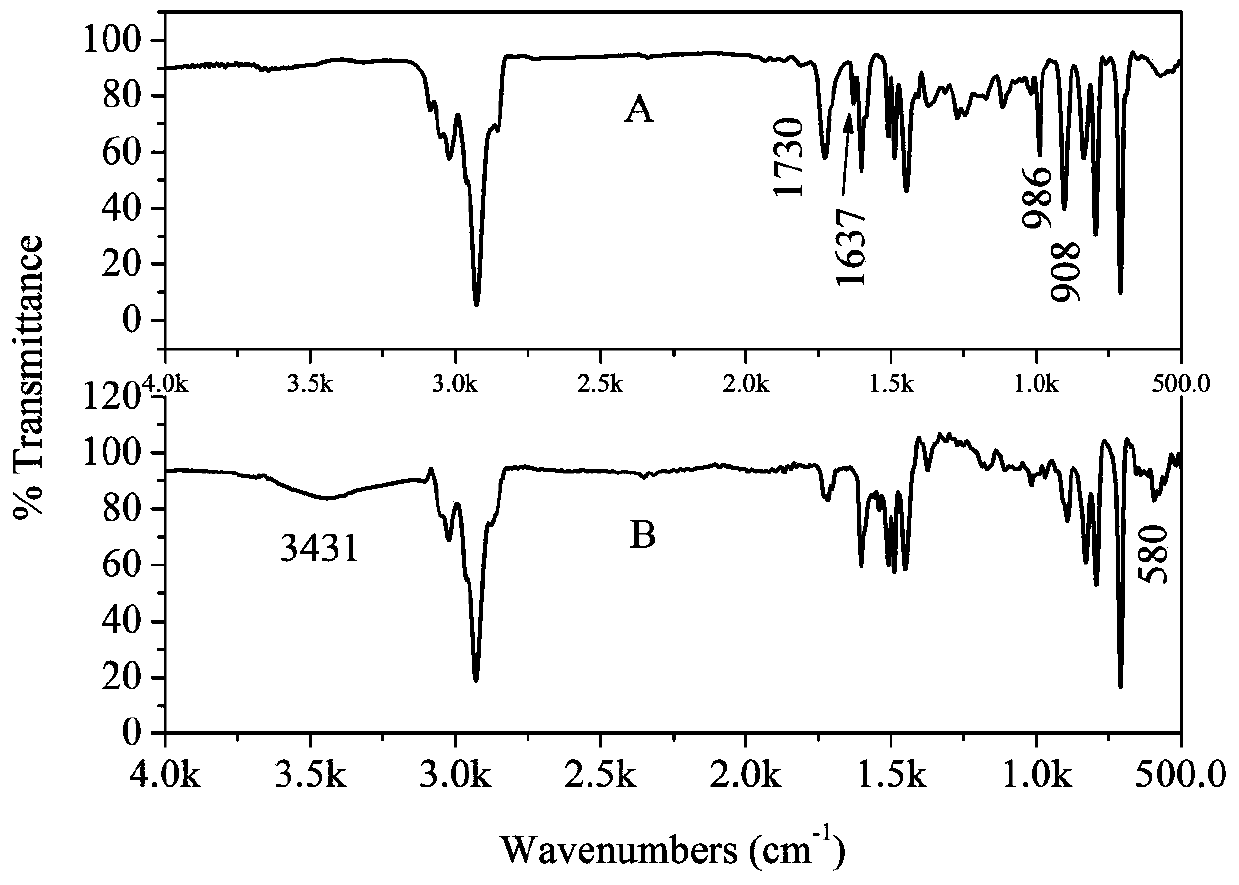

[0058] 500 g of the water phase was prepared using 5.0 g of gelatin and 100.0 g of table salt. The oil phase consisted of 21.0 g divinylbenzene, 11.7 g vinyl benzoate, 2.3 g glycidyl methacrylate, 35.0 g toluene and 1.4 g benzoyl peroxide. The oil phase was coated with 8.75g oleic acid Fe 3 o 4 After mixing evenly, add it into a three-necked flask to mix with the water phase (175g), control the stirring speed at 300rpm, raise the temperature to 60°C for 6h, and keep it at 85°C for 6h. Wash the obtained resin white balls (45.2g) with ethanol and pure water, dry them, swell in dichloroethane for 6 hours, add 22.6g of anhydrous ferric chloride and react at 80°C for 12 hours to obtain a highly cross-linked resin . Add highly cross-linked spheres (43.5g) into 261g of 5% sodium hydroxide solution, react at 60°C for 5 hours, and after cooling, centrifuge the resin, wash and dry with ethanol-pure water to obtain hydrophilic and high specific surface area magnetism resin. The resu...

Embodiment 2

[0063] 1000 g of the aqueous phase was prepared using 5.0 g of gelatin and 100.0 g of table salt. The oil phase consisted of 10.0 g divinylbenzene, 20.0 g vinyl benzoate, 3.3 g glycidyl methacrylate, 40.0 g toluene and 2.7 g benzoyl peroxide. The oil phase was coated with 2.7g oleic acid gamma-Fe 2 o 3 After mixing evenly, add it into a three-necked flask to mix with the water phase (696.4g), control the stirring speed at 400rpm, raise the temperature to 80°C for 3h, and keep at 90°C for 5h. Wash the obtained white ball resin (31.5g) with ethanol and pure water, dry it, swell it in dichloroethane for 9 hours, add 6.3g of anhydrous ferric chloride and react it at 80°C for 9 hours to obtain a highly cross-linked resin . Add highly cross-linked balls (30.2g) into 241.6g of 5% sodium hydroxide solution, react at 70°C for 5 hours, and after cooling, centrifuge the resin, wash and dry with ethanol-pure water to obtain hydrophilic and high specific surface area magnetic resin.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com