Method for extraction of scandium in titanium chloride smoke dusts and fused salt chloride residues by using compound extraction agent

A composite extraction agent and molten salt chloride slag technology, applied in the field of scandium extraction, can solve the problems of low extraction rate, low recovery rate of scandium, large pollution and other problems, and achieve the convenience of industrial production and high total recovery rate of scandium , Improve the effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

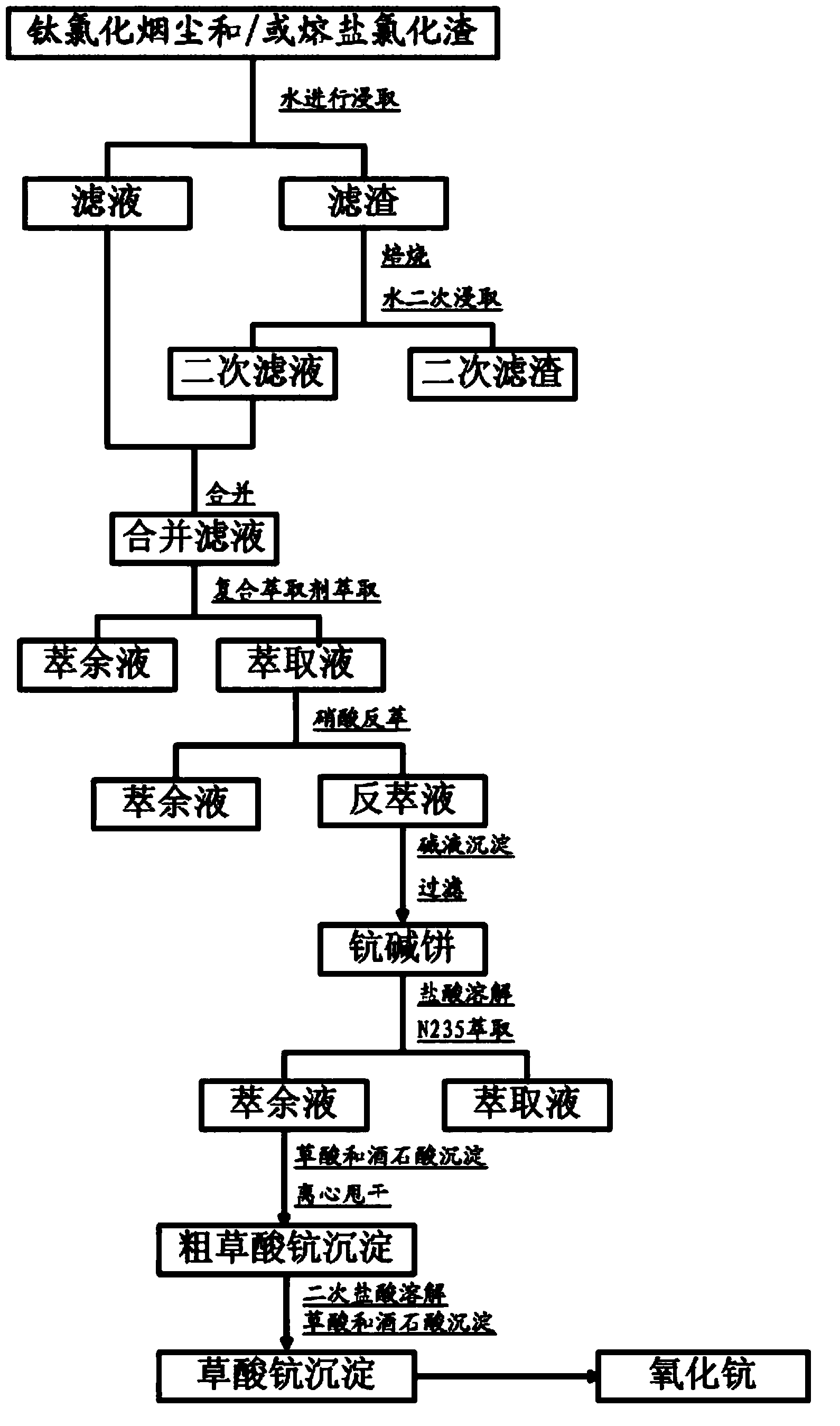

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 200L of water to 100kg of titanium chloride fume (scandium content is 0.080%) for leaching for 8 hours, filter to obtain 190L of filtrate and 45kg of filter residue;

[0033] (2) Add 45kg of calcium chloride to the filter residue for roasting, then add 90L of 6M hydrochloric acid solution to the roasted filter residue for leaching for 8 hours, and filter to obtain 85L of filtrate and 24kg of filter residue (scandium content is 0.0092%), scandium leaching rate 97.24%;

[0034] (3) Combine the filtrates (chlorine content is 325g / L), add 150L of composite extractant to the filtrate for extraction, and obtain raffinate 275L (scandium content is 12mg / L), scandium extraction rate is 95.69%; The weight ratio is 10% P350, 35% TBP, 20% 2-octanol, and the balance is kerosene

[0035] (4) Add 40L of 5.0M nitric acid to the extractant for back extraction, the scandium content of the back extraction solution is 1.75g / L, and the scandium back extraction rate is 95.51%; add 1...

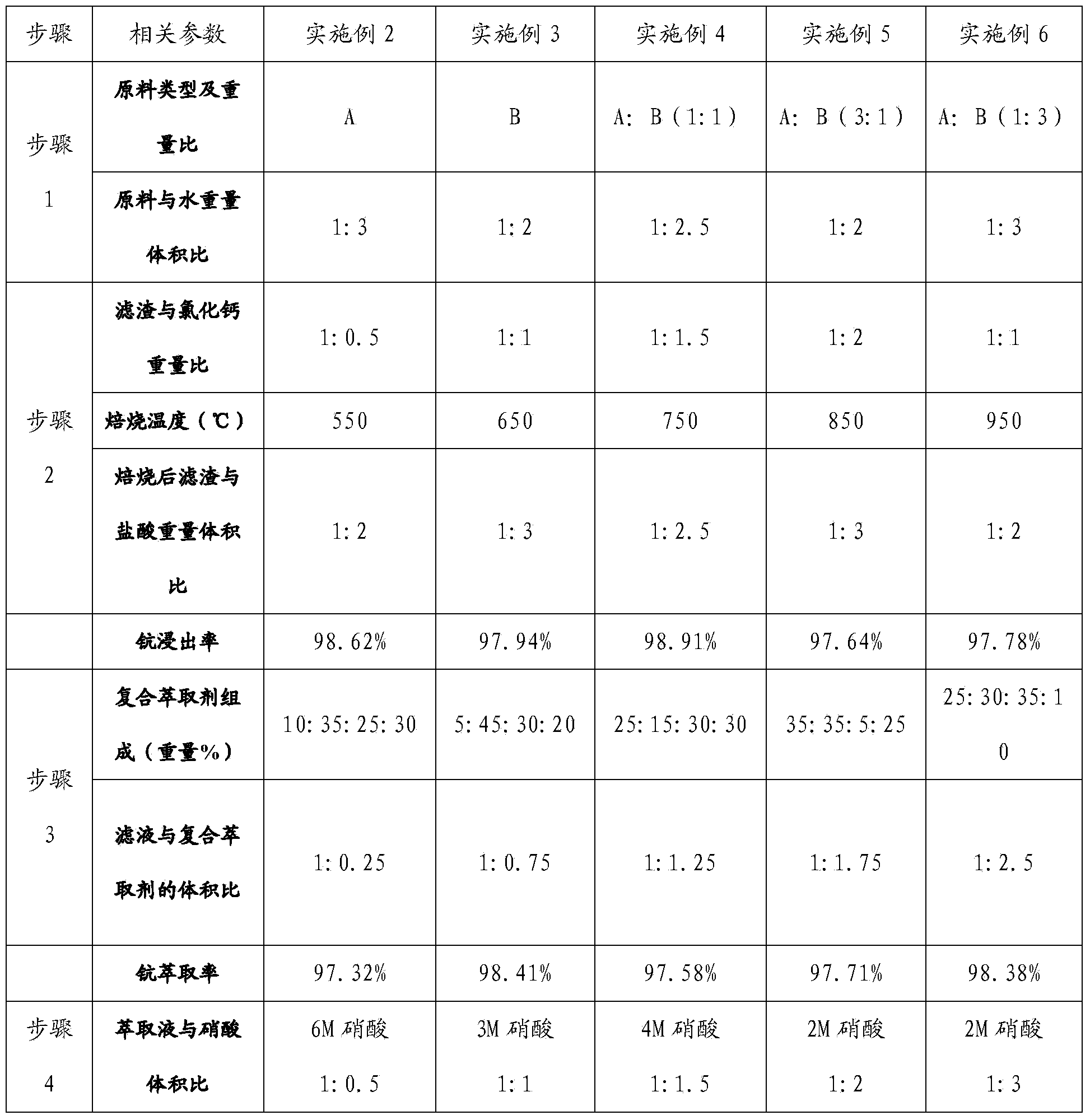

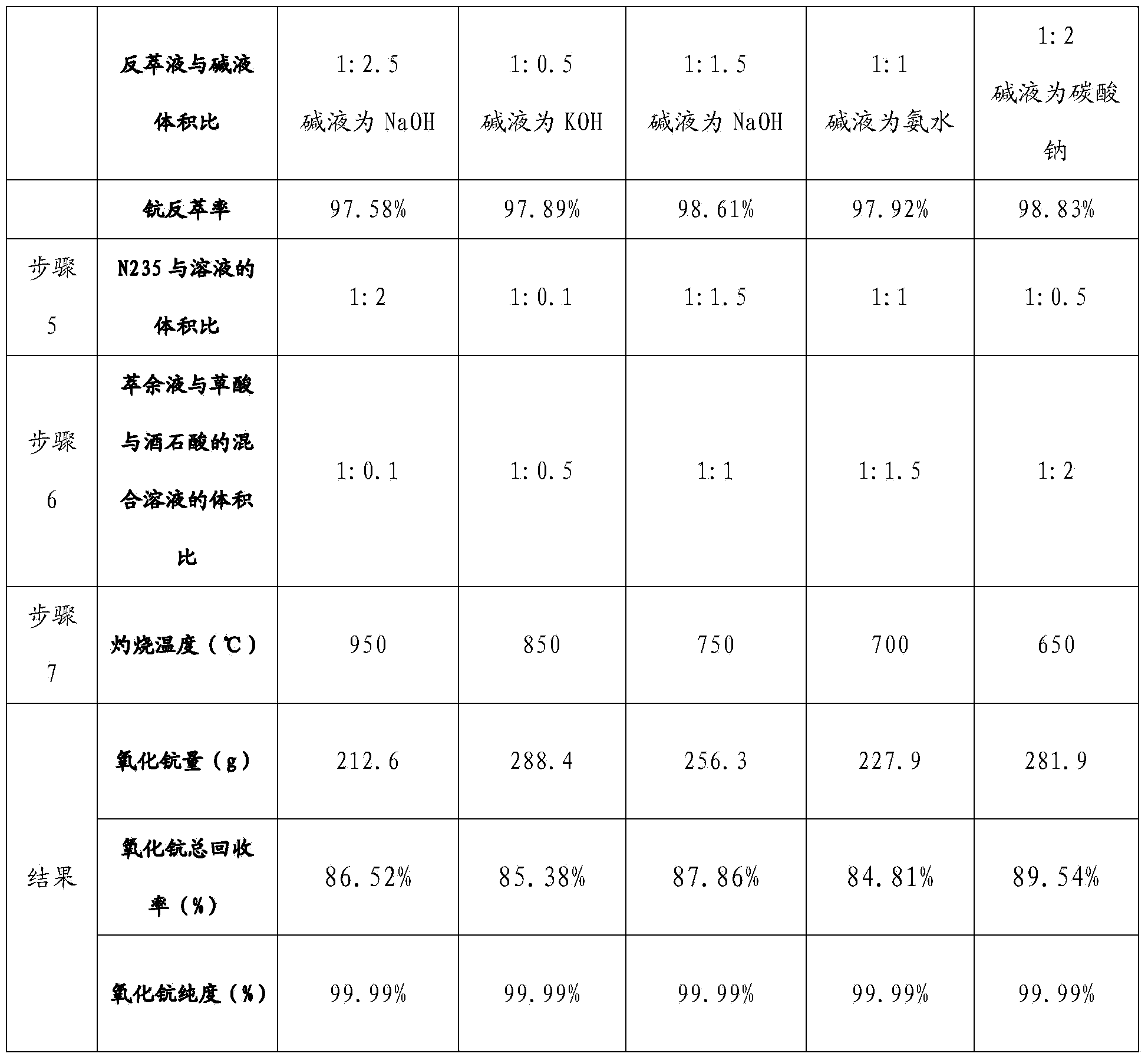

Embodiment 2-10

[0040] Method is with embodiment 1, and concrete parameter and effect are shown in the following table:

[0041]

[0042]

[0043]In the table, A represents titanium chloride fume, B represents titanium molten salt chloride slag (scandium content 0.11%), and the total amount of raw materials is 100kg; the ratio of composite extractant refers to P350: TBP: 2-octanol: kerosene.

Embodiment 11

[0044] Embodiment 11 Composite extractant comparative test

[0045] Using different extractants and proportions, the extraction test was carried out. The extract was selected from the combined extract of steps 1 and 2 in the above-mentioned embodiment 1. The specific composition and extraction rate are shown in the following table:

[0046] serial number

[0047] P507

[0048] No. 1-3 is the composition of the extractant of the present invention, and No. 4-10 is the contrast extractant. As can be seen from the above table, the extraction rate of the extractant of the present invention is obviously higher than that of the contrast extractant. It should be noted that the data in the above table are only exemplary data to show the superiority of the extractant of the present invention, and the applicant's large number of screening test data are not listed here one by one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com