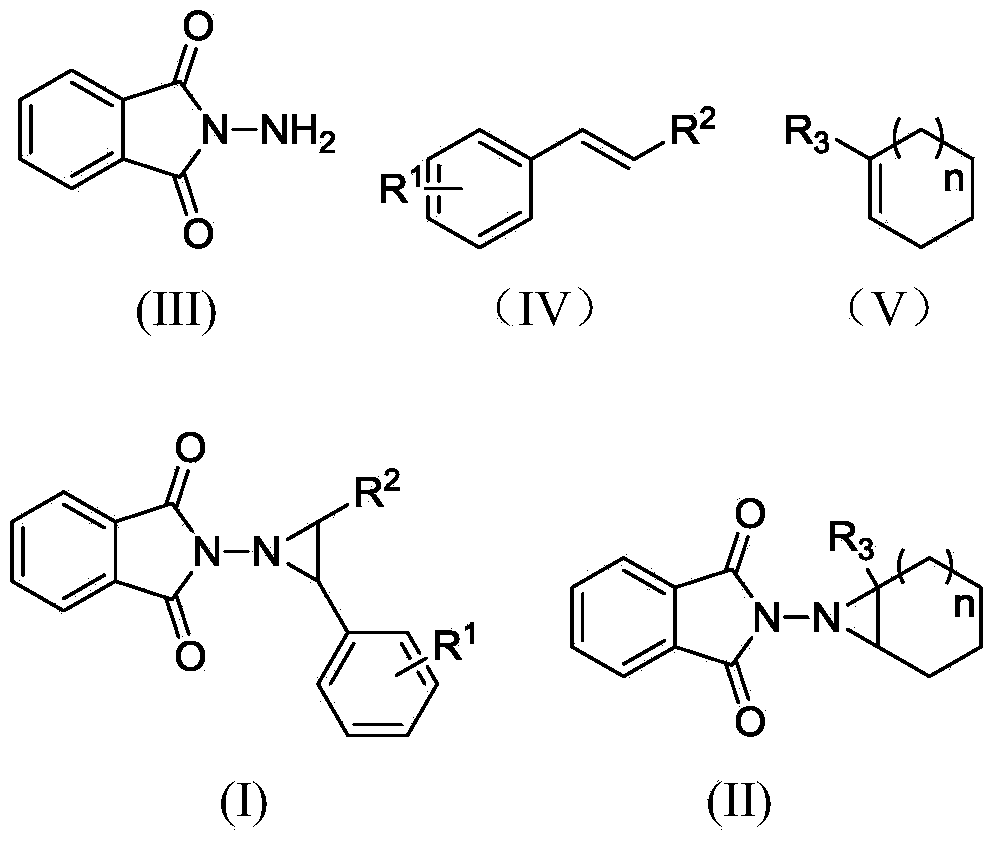

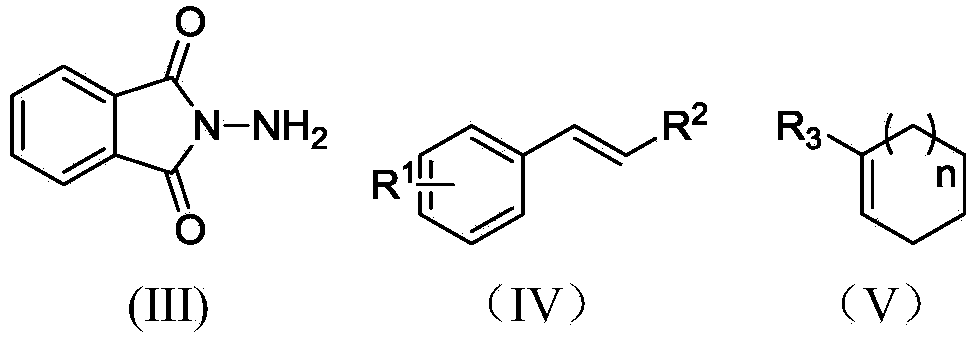

Electrochemical catalytic synthesis method of aziridine compounds

The technology of aziridine and synthesis method is applied in the field of electrochemical catalytic synthesis of aziridine compounds, which can solve the problems of complex electrolysis device, high decomposition voltage and high cost, and achieve cheap and easy-to-obtain electrode materials and high reaction efficiency. The effect of mild conditions and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Electrochemically catalyzed aziridine of styrene

[0029] In a 50mL single-chamber electrolytic cell, add N-aminophthalimide (1.3mmol), styrene (1mmol), potassium carbonate (1mmol) and tetrabutylammonium iodide (0.2mmol) to the solution In 15mL 2,2,2-trifluoroethanol solution with 0.1M triethylamine / acetic acid, with glassy carbon electrode as anode and iron plate as cathode, the temperature is 4mA / cm 2 Electrolysis under constant current, stirring at room temperature, when the energization reaches 3F / mol, stop the electrolysis, remove the solvent, dissolve with dichloromethane, wash three times with water, and separate by column chromatography to obtain N-(aminophthaloyl Imine)-2-phenylaziridine. Yield: 50%.

[0030]

[0031] yellow solid;149.4-150.3℃; 1 H NMR (400MHz, CDCl3): δ=7.83-7.80(m,2H), 7.73-7.71(m,2H), 7.37(d,J=8Hz,2H), 7.22(d,J=8Hz,2H), 3.59(dd,J=8.0,6.0Hz,1H), 2.89(dd,J=8,2.4Hz,1H), 2.81(dd,J=6,2.4Hz,1H).

Embodiment 2

[0032] Example 2: Electrochemically catalyzed aziridine of styrene

[0033] In a 50mL single-chamber electrolytic cell, add N-aminophthalimide (1.3mmol), styrene (1mmol), potassium carbonate (1mmol) and tetrabutylammonium iodide (0.2mmol) to the solution In 15mL 2,2,2-trifluoroethanol solution containing 0.05M lithium perchlorate, the glassy carbon electrode is used as the anode and the iron sheet is used as the cathode. The temperature is 4mA / cm 2 Electrolysis under constant current, stirring at room temperature, when the energization reaches 3F / mol, stop the electrolysis, remove the solvent, dissolve with dichloromethane, wash three times with water, and separate by column chromatography to obtain N-(aminophthaloyl Imine)-2-phenylaziridine. Yield: 67%.

Embodiment 3

[0034] Example 3: Electrochemically catalyzed aziridine of styrene

[0035] In a 50mL single-chamber electrolytic cell, add N-aminophthalimide (1.3mmol), styrene (1mmol), potassium carbonate (1mmol) and tetraethylammonium iodide (0.2mmol) to the solution In 15mL 2,2,2-trifluoroethanol solution containing 0.05M lithium perchlorate, the glassy carbon electrode is used as the anode and the iron sheet is used as the cathode. The temperature is 4mA / cm 2 Electrolysis under constant current, stirring at room temperature, when the energization reaches 3F / mol, stop the electrolysis, remove the solvent, dissolve with dichloromethane, wash three times with water, and separate by column chromatography to obtain N-(aminophthaloyl Imine)-2-phenylaziridine. Yield: 51%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com