Preparation method of nanocellulose film precipitated by applying water solution

A technology of nanocellulose and application of aqueous solution, applied in the field of preparation of cellulose, nanocellulose and nanocellulose film, can solve the problems of difficult recovery and processing reaction, low yield, and high requirements for reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

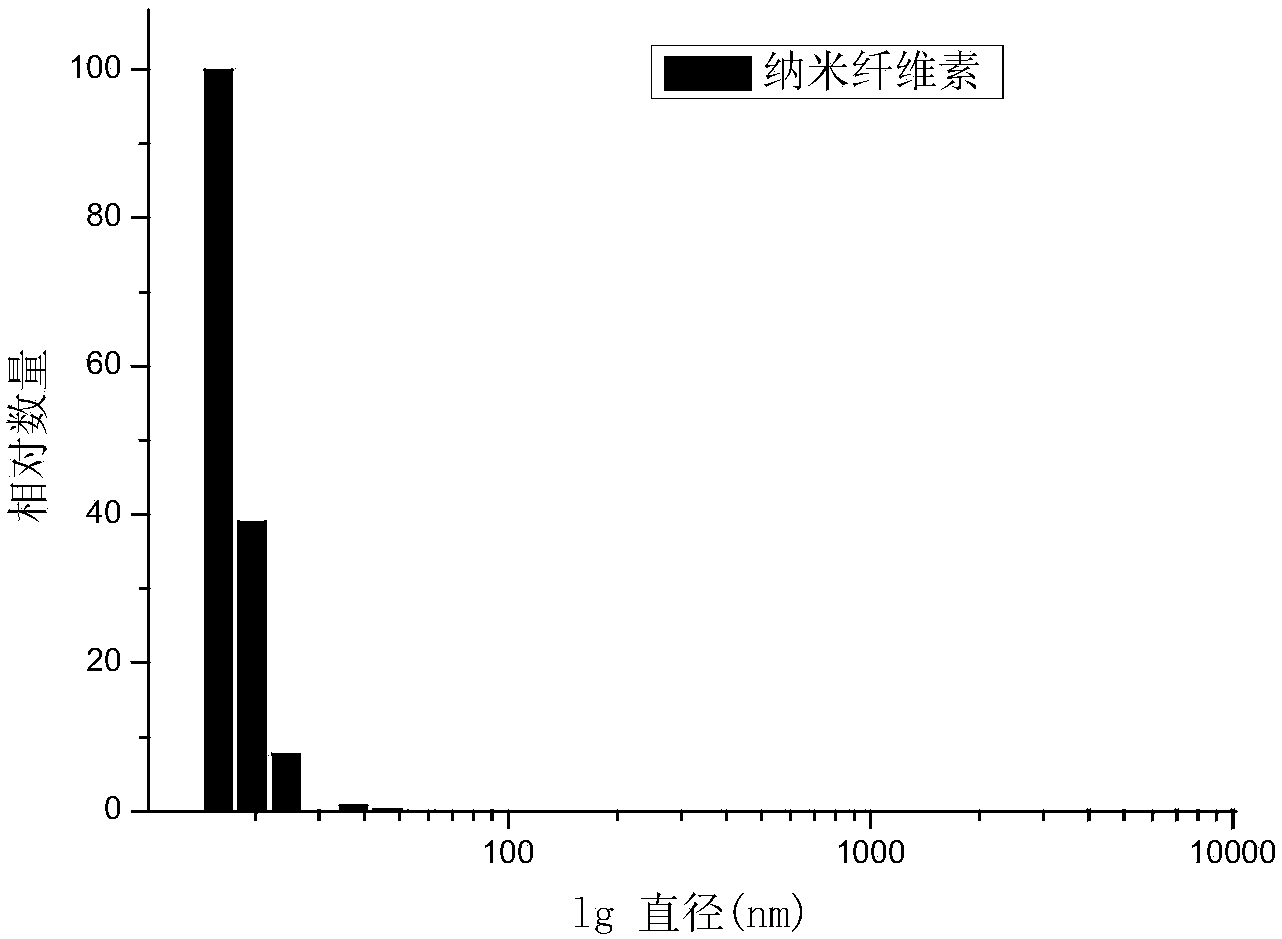

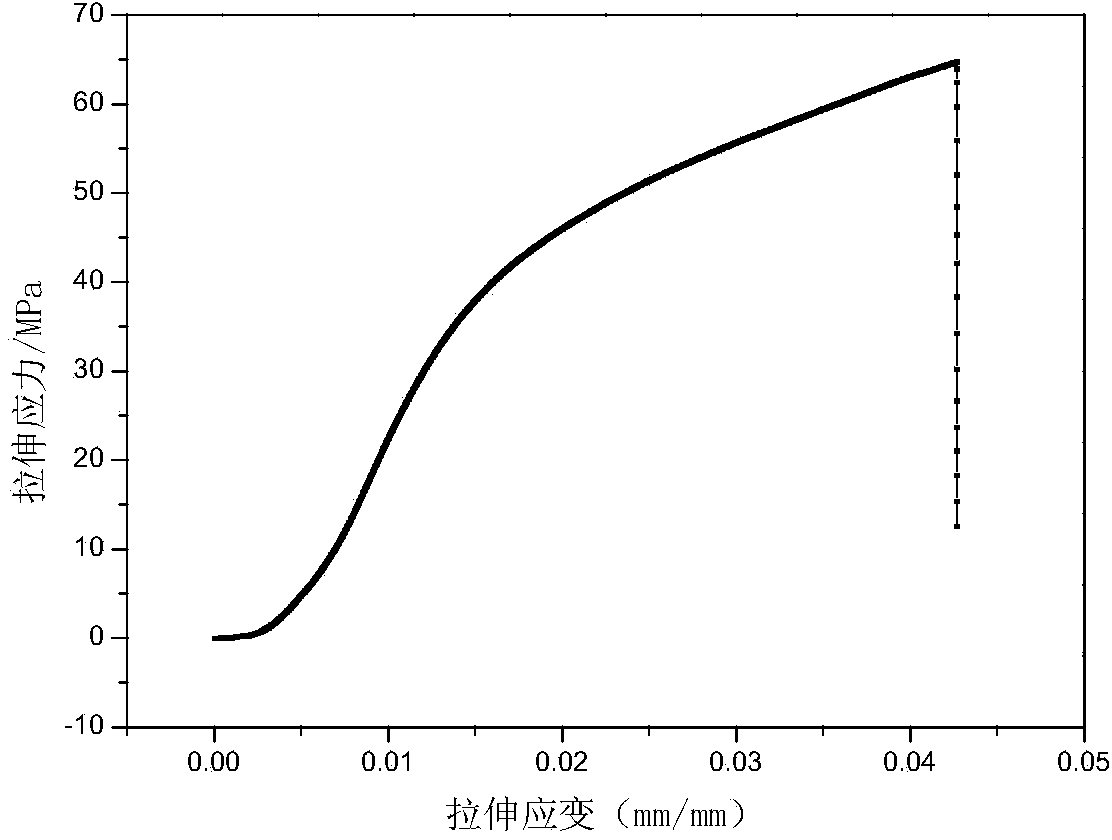

[0031] Weigh 1g of bamboo dissolving pulp dry pulp, and dissolve the bamboo dissolving pulp dry pulp in the mixed solution of 100ml sodium hydroxide, urea and water under the condition of -8°C, the content of sodium hydroxide, urea and water in the mixed solution is The mass ratio is 7:12:81. After stirring for 3 minutes under the condition of maintaining -8°C, centrifuge at a centrifugal speed of 10,000 r / min for 10 minutes to remove impurities, and obtain 100 ml of a clear and viscous cellulose solution. After naturally warming up to room temperature, 100ml of water was added dropwise to the 100ml cellulose solution while stirring, and the cellulose molecules were gradually precipitated to obtain a nanocellulose colloidal dispersion. Two PVDF filter membranes with a pore size of 0.22 μm (Polyvinylidene Fluoride GVWP14250, 0.22 μm pore size, Millipore, Ireland) were stacked, and the filter press (142-mm Millipore Hazardous Waste Filtration System, Millipore, Ireland) was used...

Embodiment 2

[0037] Weigh 1g of dry hardwood bleached pulp, and dissolve the dry hardwood bleached pulp in 100ml of a mixed solution of sodium hydroxide, urea and water at -8°C. In the mixed solution, sodium hydroxide, urea and The mass ratio of water is 5:15:80. After stirring for 3 minutes under the condition of maintaining -8°C, centrifuge at a centrifugal speed of 10,000 r / min for 10 minutes to remove impurities, and obtain 100 ml of a clear and viscous cellulose solution. After naturally warming up to room temperature, 150 ml of water was added dropwise to 100 ml of cellulose solution while stirring, and the cellulose molecules were gradually precipitated to obtain a nanocellulose colloidal dispersion. Two PVDF filter membranes with a pore size of 0.22 μm (Polyvinylidene Fluoride GVWP14250, 0.22 μm pore size, Millipore, Ireland) were stacked, and the filter press (142-mm Millipore Hazardous Waste Filtration System, Millipore, Ireland) was used to prepare The nanocellulose colloidal d...

Embodiment 3

[0039] Weigh 1g of microcrystalline cellulose, and dissolve the microcrystalline cellulose in a mixed solution of 100ml of sodium hydroxide, urea and water at -15°C, the mass ratio of sodium hydroxide, urea and water in the mixed solution is 10 :10:80. After stirring for 3 minutes under the condition of maintaining -15°C, centrifuge at a centrifugal speed of 10000r / min for 10 minutes to remove impurities, and obtain 100ml of clear viscous cellulose solution. After naturally warming up to room temperature, 200ml of water was added dropwise to 100ml of cellulose solution at room temperature while stirring, and the cellulose molecules were gradually precipitated to obtain nanocellulose colloidal dispersion. Two PVDF filter membranes with a pore size of 0.22 μm (Polyvinylidene Fluoride GVWP14250, 0.22 μm pore size, Millipore, Ireland) were stacked, and the filter press (142-mm Millipore Hazardous Waste Filtration System, Millipore, Ireland) was used to prepare The nanocellulose c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com