Hydrocarbon-resistant indoor ultrathin fireproofing coating for steel structures

A fire-resistant coating, ultra-thin technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve problems such as potential safety hazards, environmental pollution, and limited application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Hydrocarbon-resistant indoor ultra-thin steel structure fireproof coating, the raw material composition includes A component and B component, of which A component includes high chlorinated polyethylene, tetrabromobisphenol, ammonium polyphosphate, melamine, pentaerythritol, antimony trioxide , chlorinated paraffin, titanium dioxide, mixed solvent, component B is polyamide 300#; components A and B are mixed at a mass ratio of 1.5:9.2;

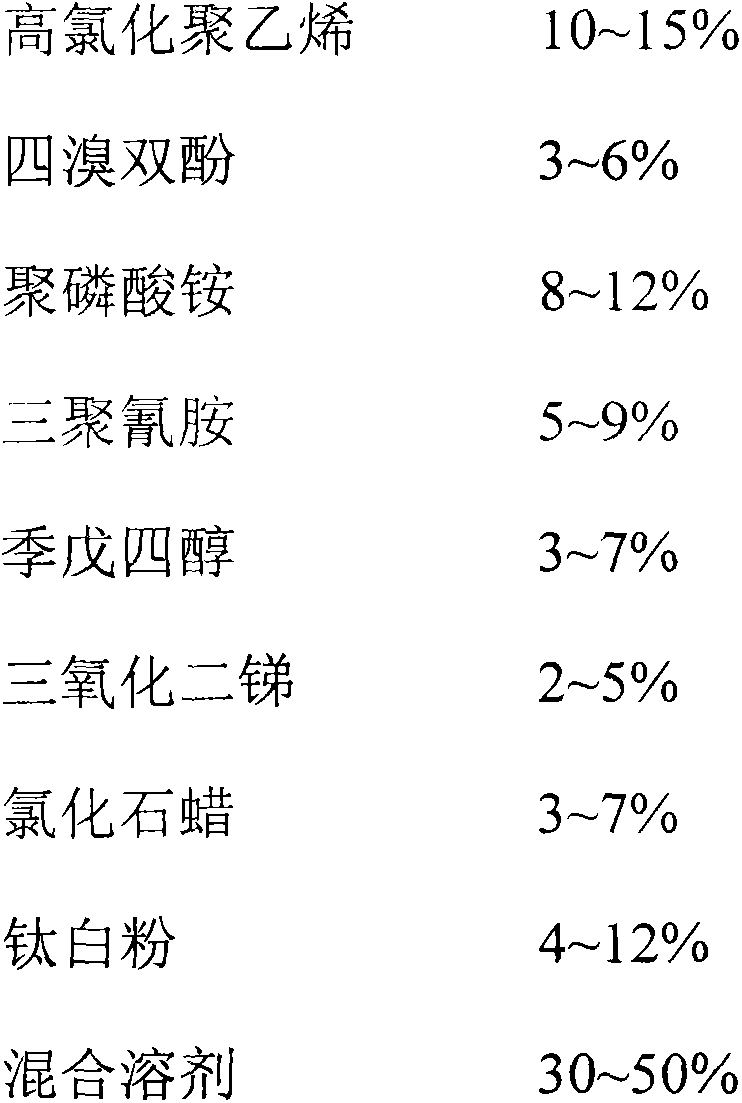

[0020] The content of each component by mass percentage in component A is as follows:

[0021]

[0022] Wherein the mixed solvent comprises: cyclohexanone: butanol: butyl acetate: ethyl acetate, the mass ratio is: 1:0.6:0.5:1.

Embodiment 2

[0024] Hydrocarbon-resistant indoor ultra-thin steel structure fireproof coating, the raw material composition includes A component and B component, of which A component includes high chlorinated polyethylene, tetrabromobisphenol, ammonium polyphosphate, melamine, pentaerythritol, antimony trioxide , chlorinated paraffin, titanium dioxide, mixed solvent, component B is polyamide 300#; components A and B are mixed at a mass ratio of 1.5:9.4;

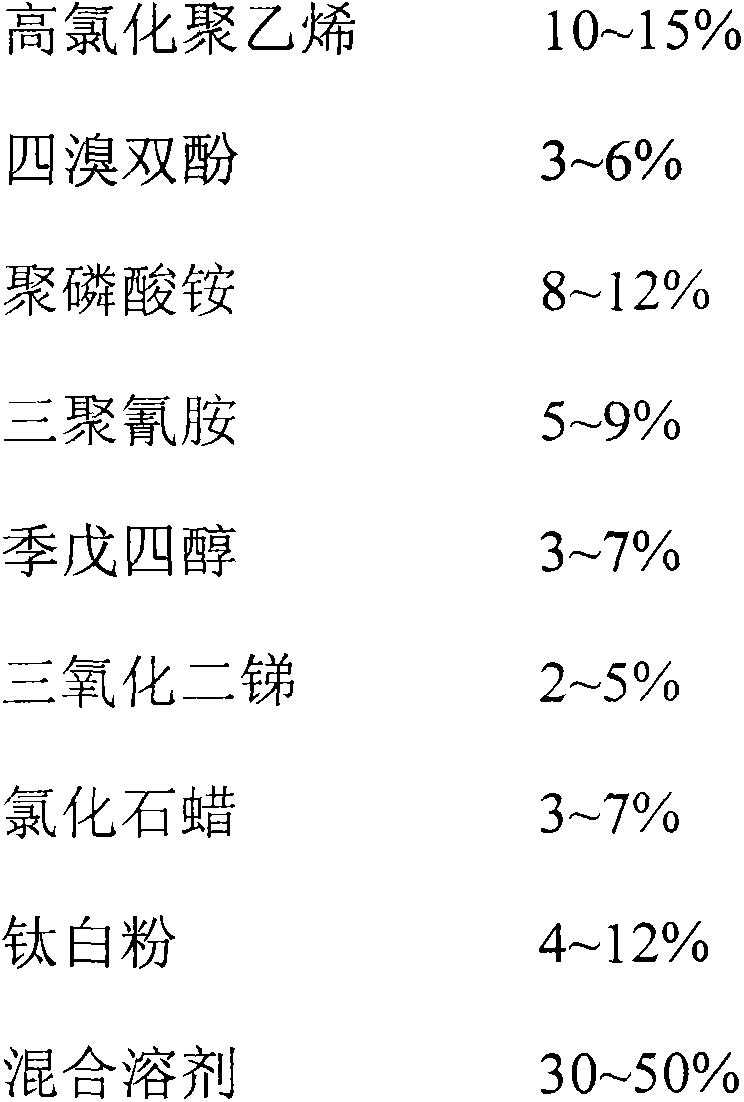

[0025] The content of each component by mass percentage in component A is as follows:

[0026]

[0027]

[0028] Wherein the mixed solvent includes: cyclohexanone: butanol: butyl acetate: ethyl acetate, the mass ratio is: 1:0.5:0.7:1.2.

Embodiment 3

[0030] Hydrocarbon-resistant indoor ultra-thin steel structure fireproof coating, the raw material composition includes A component and B component, of which A component includes high chlorinated polyethylene, tetrabromobisphenol, ammonium polyphosphate, melamine, pentaerythritol, antimony trioxide , chlorinated paraffin, titanium dioxide, mixed solvent, component B is polyamide 300#; components A and B are mixed at a mass ratio of 1.5:9.8;

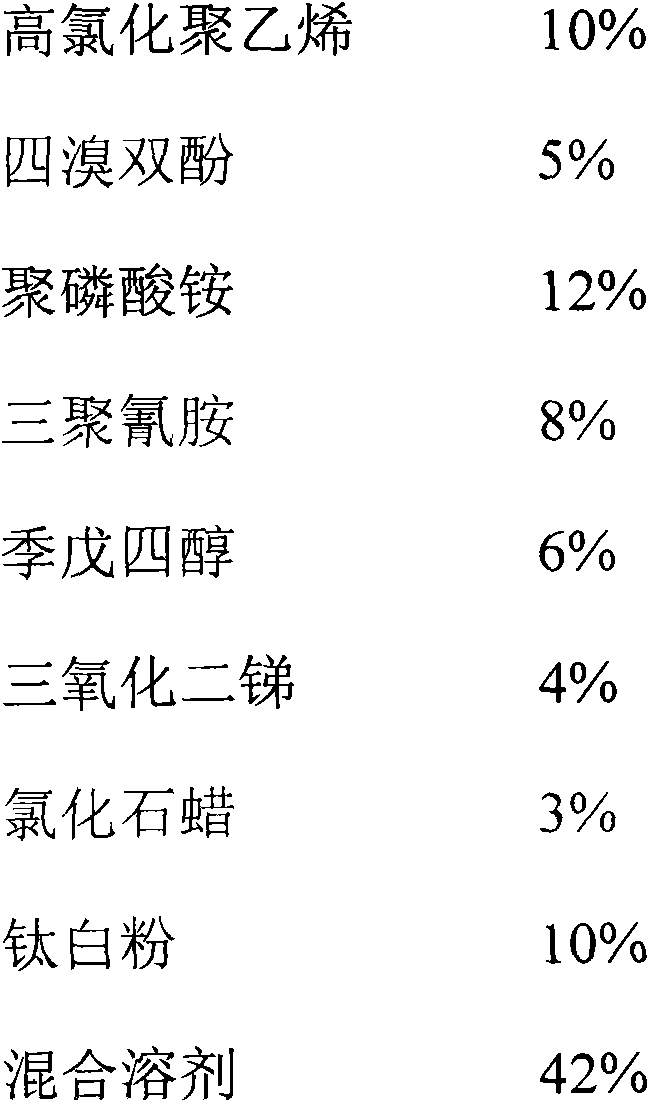

[0031] The content of each component by mass percentage in component A is as follows:

[0032]

[0033] Wherein the mixed solvent comprises: cyclohexanone: butanol: butyl acetate: ethyl acetate, the mass ratio is: 1: (0.5-0.8): (0.5-0.8): (1-1.2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com