Red up-conversion material of oxyfluoride and preparation method thereof

A technology of oxyfluoride and conversion materials, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of inconvenient large-scale production, harsh preparation conditions, low color purity, etc., achieve good up-conversion performance, reduce calcination temperature, The effect of increasing the luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

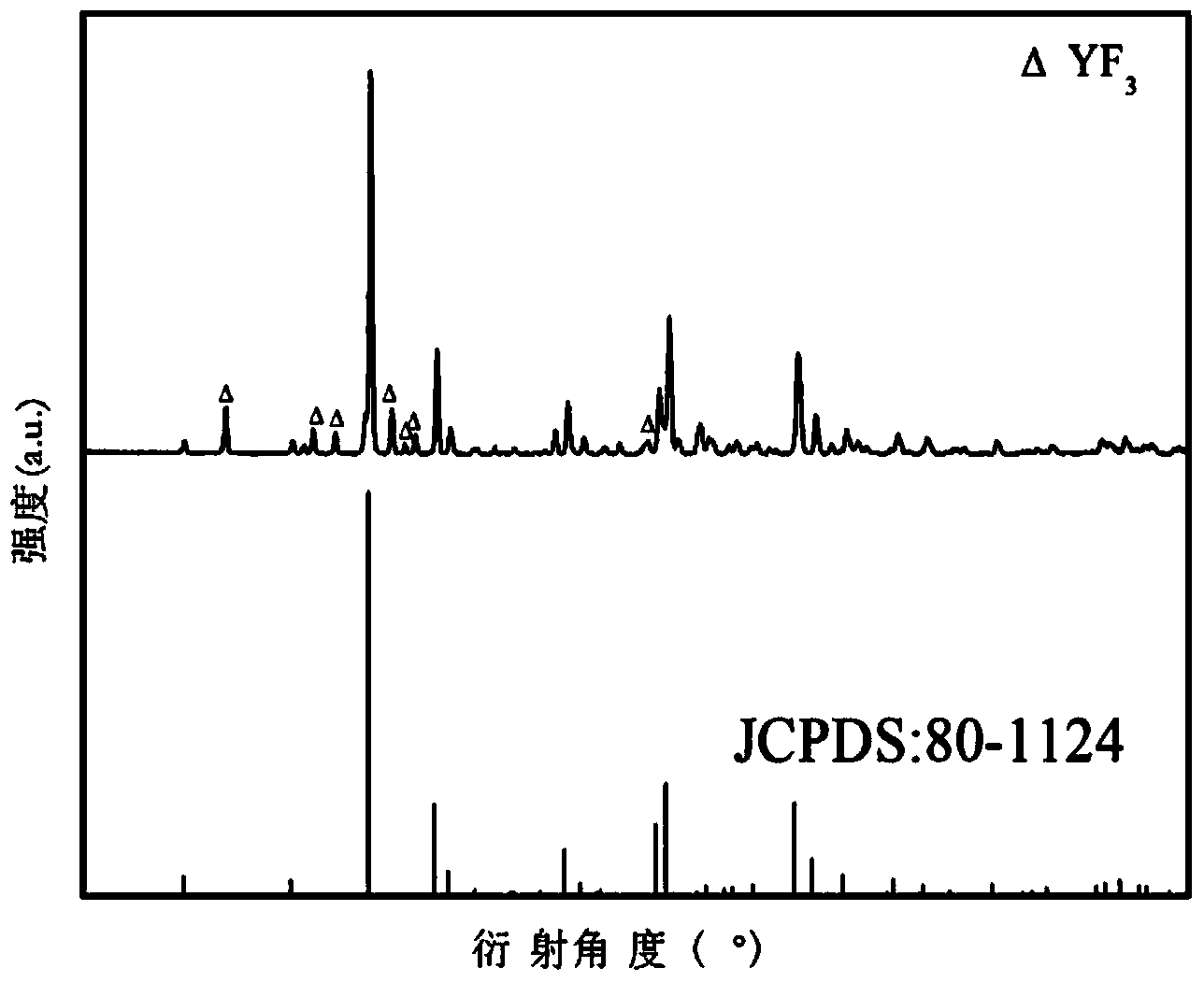

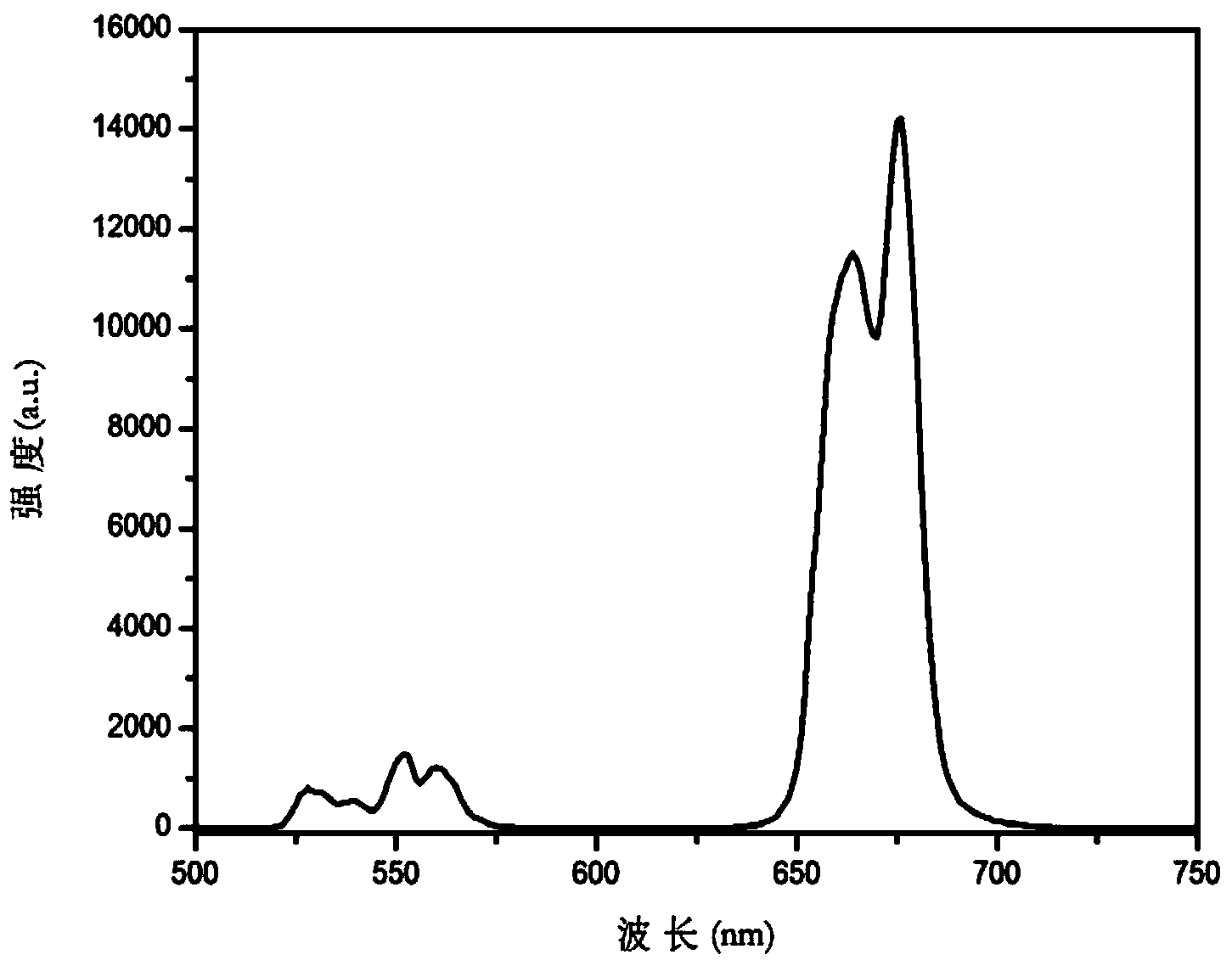

Embodiment 1

[0039] (1) Add 4.7309g of YCl 3 ·6H 2 O, 1.55gYbCl 3 ·6H 2 O, 0.1527gErCl 3 ·6H 2 O was dissolved in 50g of deionized water, stirred to make it fully dissolved, and a transparent mixed solution of Y, Yb and Er was obtained;

[0040] (2) Dissolve 2.3718g of ammonium bicarbonate solid in 30g of deionized water to obtain a transparent ammonium bicarbonate solution;

[0041] (3) Add the ammonium bicarbonate solution to the mixed solution of Y, Yb and Er under stirring conditions, age for 1 hour, and obtain a slurry after slow reaction;

[0042] (4) Filter the slurry obtained above, collect the precipitate, wash the precipitate with deionized water for 2 to 3 times, and dry at 80°C for 10 hours to obtain a white powder;

[0043] (5) Put the white powder in a muffle furnace for calcination, the calcination temperature is 1200°C, the calcination time is 3h, and a white solid is obtained;

[0044] (6) Mix and grind the white solid with 0.0415g of lithium fluoride and 1.1408g of...

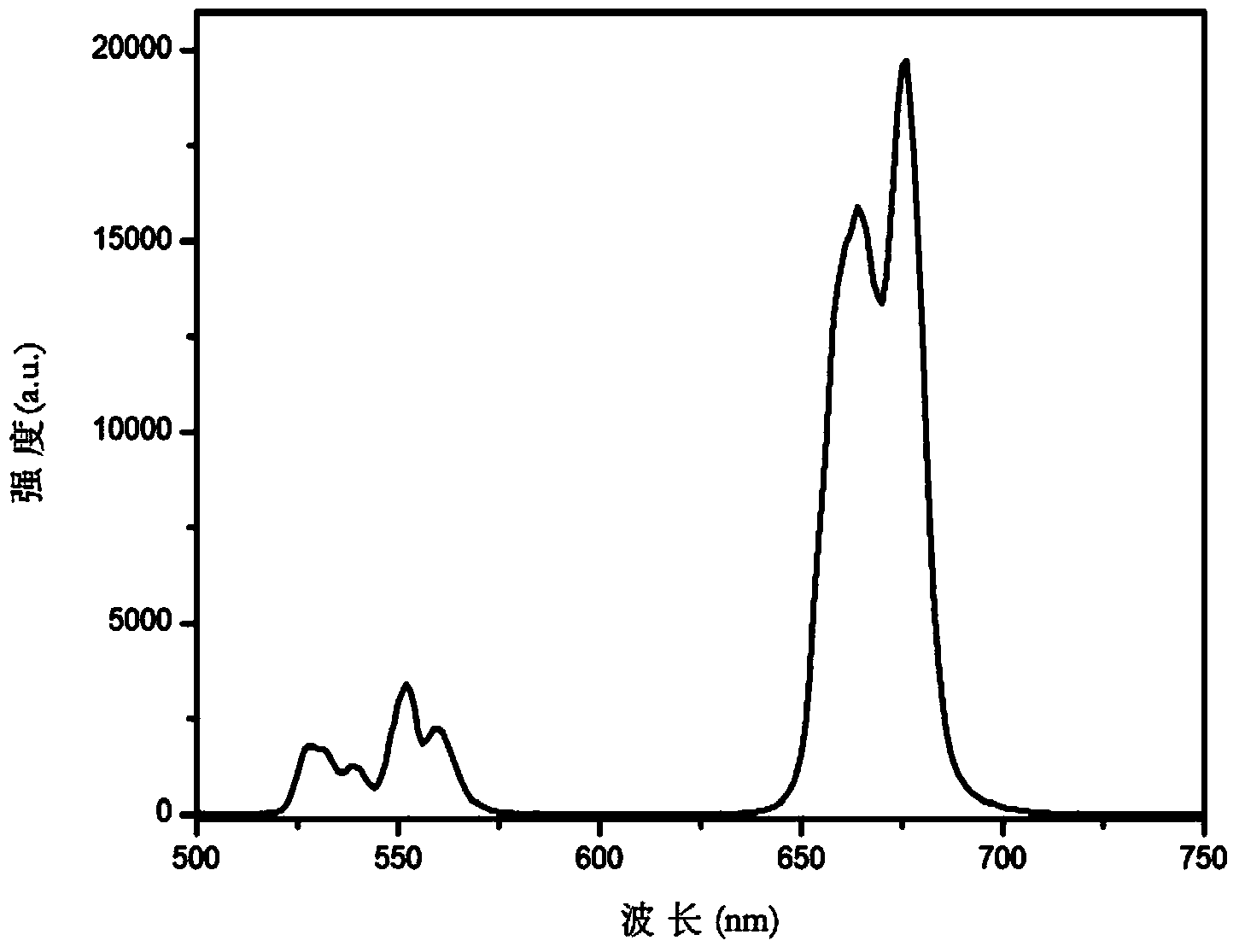

Embodiment 2

[0049] (1) 2.9113g of YCl 3 ·6H 2 O, 3.8749gYbCl 3 ·6H 2 O, 0.1527gErCl 3 ·6H 2 O was dissolved in 50g of deionized water, stirred to make it fully dissolved, and a transparent mixed solution of Y, Yb and Er was obtained;

[0050] (2) Dissolve 2.8824g of ammonium carbonate solid in 30g of deionized water to obtain a transparent ammonium carbonate solution;

[0051] (3) Add the ammonium carbonate solution to the mixed solution of Y, Yb and Er under stirring conditions, age for 1 hour, and obtain a slurry after slow reaction;

[0052] (4) Filter the slurry obtained above, collect the precipitate, wash the precipitate with ethanol for 2 to 3 times, and dry at 80°C for 10 hours to obtain a white powder;

[0053] (5) Put the white powder in a muffle furnace for calcination, the calcination temperature is 1100°C, and the calcination time is 3 hours to obtain a white solid;

[0054] (6) Mix and grind the white solid with 0.0415g lithium fluoride and 1.4816g ammonium fluoride t...

Embodiment 3

[0058] (1) 5.398g of YCl 3 ·6H 2 O, 0.775gYbCl 3 ·6H 2 O, 0.0763gErCl 3 ·6H 2 O was dissolved in 50g of deionized water, stirred to make it fully dissolved, and a transparent mixed solution of Y, Yb and Er was obtained;

[0059] (2) Dissolve 2.3718g of ammonium bicarbonate solid in 30g of deionized water to obtain a transparent ammonium bicarbonate solution;

[0060] (3) Add the ammonium bicarbonate solution to the mixed solution of Y, Yb and Er under stirring conditions, age for 1 hour, and obtain a slurry after slow reaction;

[0061] (4) Filter the slurry obtained above, collect the precipitate, wash the precipitate with deionized water for 2 to 3 times, and dry at 100°C for 8 hours to obtain a white powder;

[0062] (5) Put the white powder in a muffle furnace for calcination, the calcination temperature is 1000°C, and the calcination time is 4h to obtain a white solid;

[0063] (6) Mix and grind the white solid with 0.0415g lithium fluoride and 0.5704g ammonium bif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com