Bearing device and hydraulic machine

A bearing device and hydraulic machinery technology, which is applied in the field of hydraulic machinery and bearing devices, can solve problems such as bearing load capacity, bearing temperature and bearing performance adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

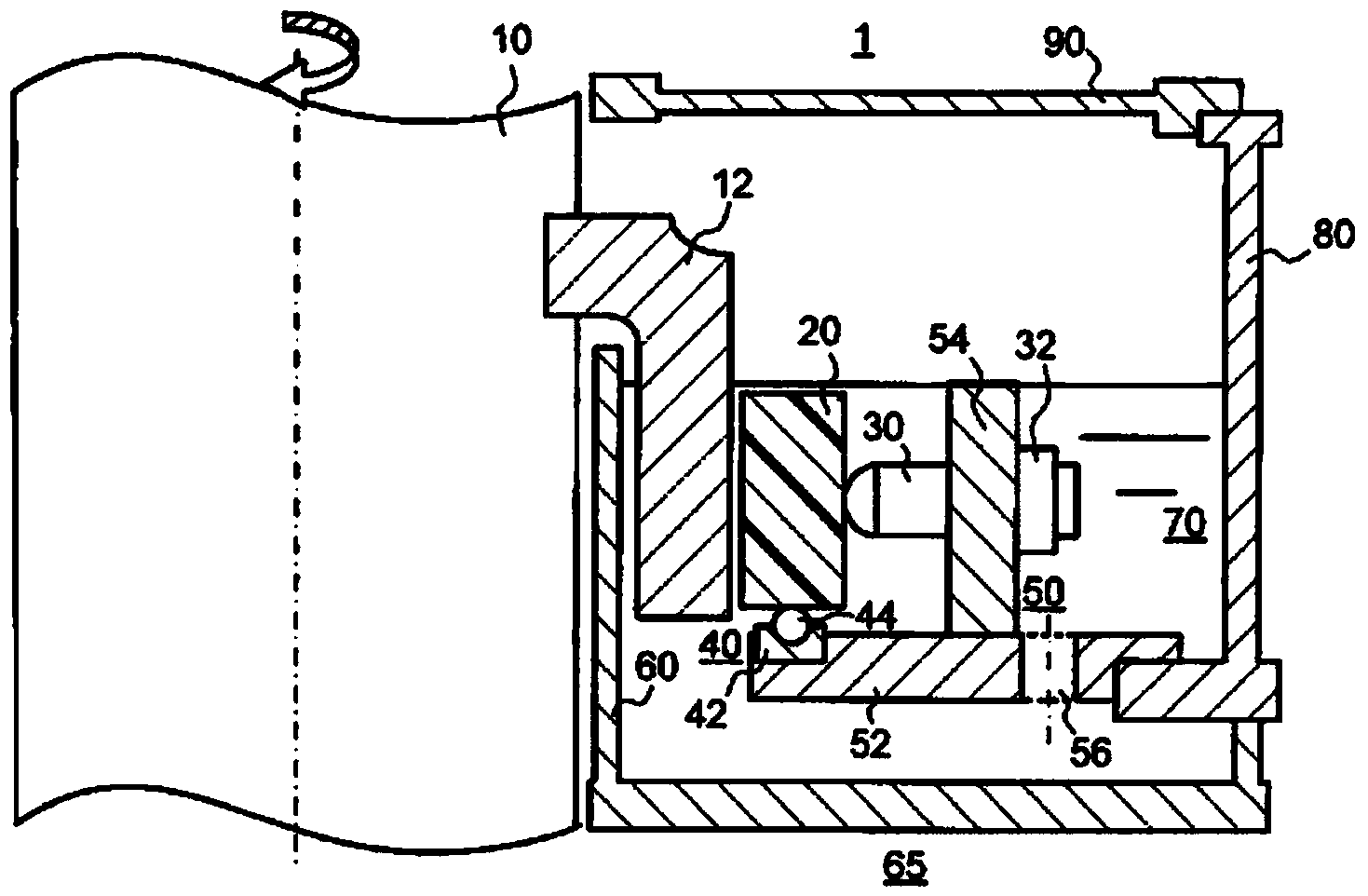

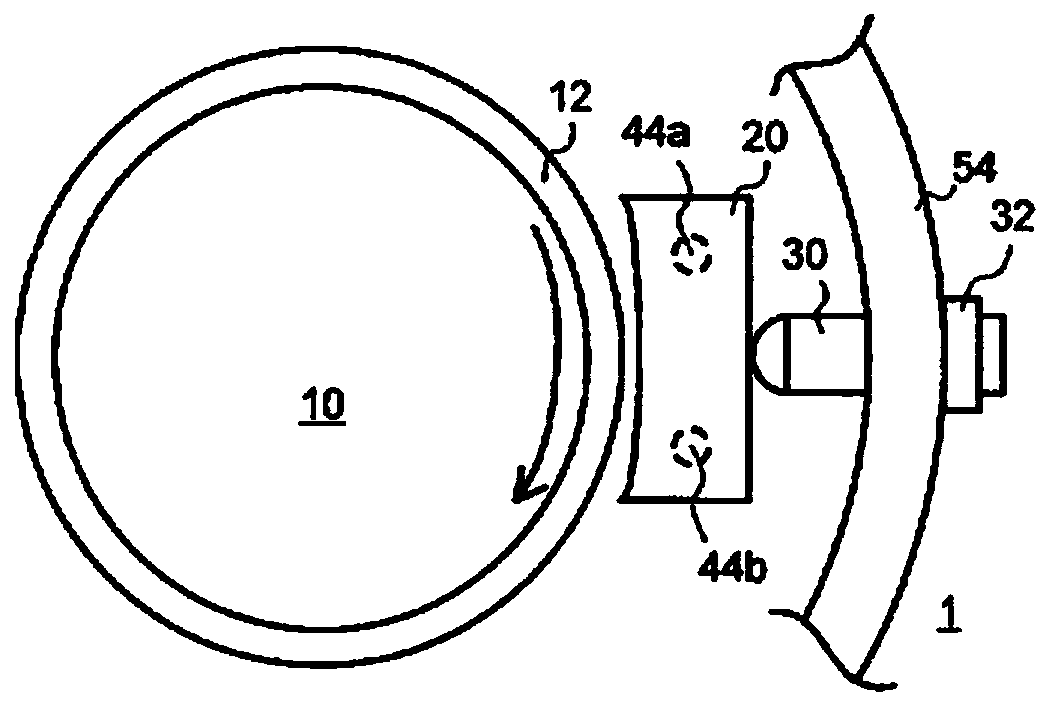

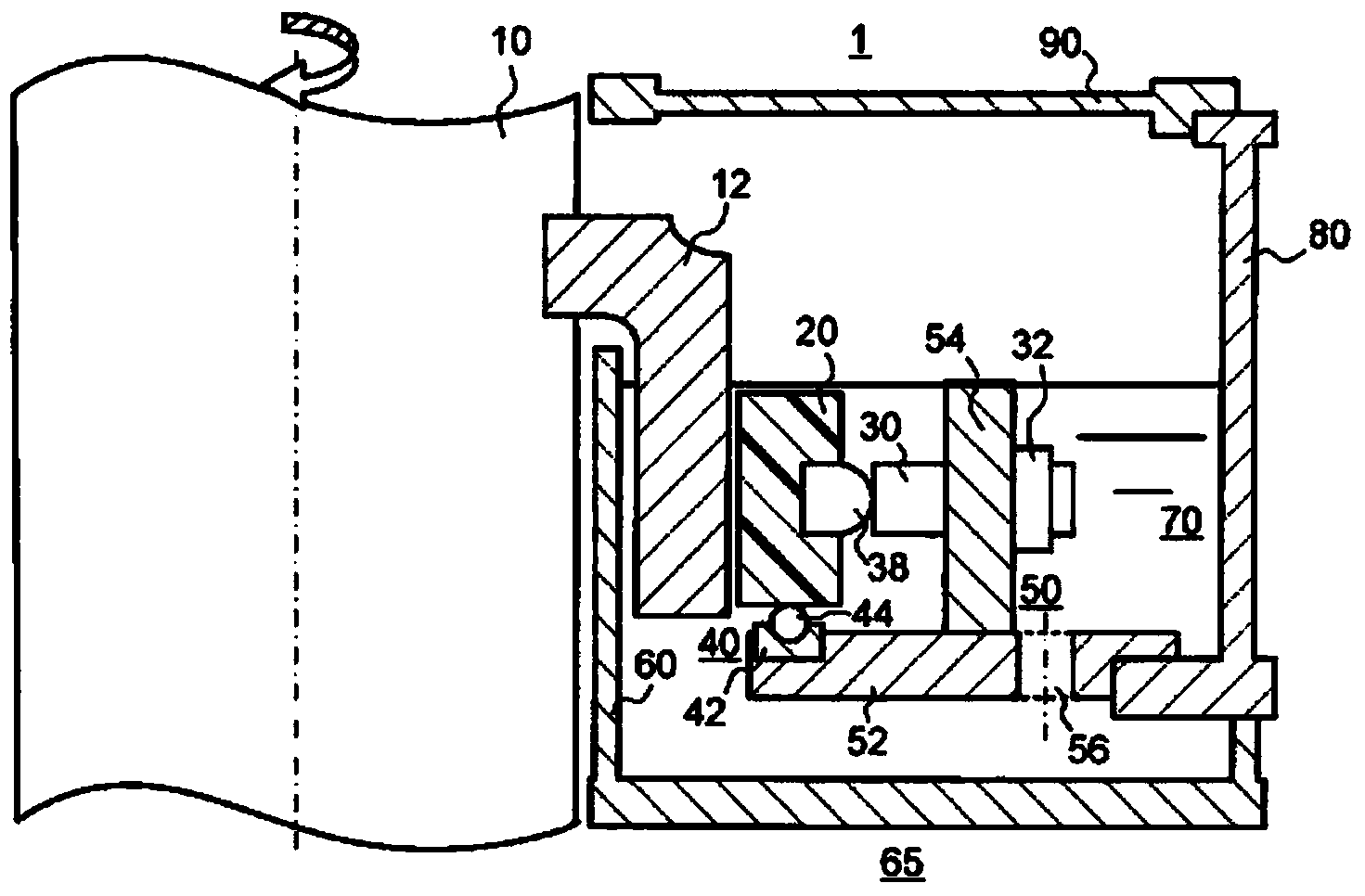

[0083] Hereinafter, embodiments will be described in detail with reference to the drawings. Figure 1A It is a longitudinal sectional view showing the structure of the guide bearing of the first embodiment, Figure 1B It is a plan view showing the structure around the bearing pad in the same guide bearing. Figure 2A , 2B and 2C for denoting Figure 1A Figure showing a modified example of the guide bearing.

[0084] Such as Figure 1AAs shown, a plurality of guide bearings 1 according to the embodiment are arranged along the peripheral surface of a rotating shaft 10 to which a vertical shaft such as a water turbine is connected, for example. The guide bearing 1 is supported at the periphery of the rotating shaft 10 by a bearing stand 80 having a wall surface coaxial with the peripheral surface, and a bearing support stand 50 extending from the wall surface of the bearing stand 80 in the direction of the rotating shaft 10 . A water cylinder 60 is arranged below the guide bear...

no. 2 approach )

[0139] Next, refer to Figure 17 ~ Figure 21 , and the second embodiment will be described in detail. The guide bearing 2 of the second embodiment is configured to actively circulate lubricating water in the guide bearing 1 of the first embodiment. In the following description, common reference numerals are assigned to elements common to those of the first embodiment, and redundant descriptions will be omitted.

[0140] Such as Figure 17 As shown, the guide bearing 2 of this embodiment has a bearing stand 80 having a wall surface coaxial with the peripheral surface and a bearing support stand extending from the wall surface of the bearing stand 80 in the direction of the rotating shaft 10 at the peripheral portion of the rotating shaft 10. 50 and was supported. A water tank 60 is arranged below the guide bearing 2 , and the guide bearing 2 is accommodated in a water tank 65 constituted by the water tank 60 and the bearing stand 80 . A water tank 65 is formed along the per...

specific example 1)

[0160] Such as Figure 22 As shown, in the guide bearing 3 of this embodiment, the lubricating water 70a is tap water containing residual chlorine or chloride ions. The ball bearing 40 is made of austenitic stainless steel. The adjusting bolt 30 and the pin bearing portion (not shown) are made of martensitic stainless steel, and the surface is treated by electroless plating or black anti-rust film treatment. Specifically, the black anti-rust film treatment method is to implement RAYDENT treatment (trade name). The bearing pad base is made of austenitic stainless steel. The shaft skirt 12 is manufactured using martensitic stainless steel and HVOF thermal spraying of a WC—Ni—Cr type ductile thermal spraying material on the surface layer, or is manufactured using austenitic stainless steel. Welded structures such as the bearing support stand 50, the water cylinder 60, the bearing stand 80, and the bearing cover 90 are made of martensitic stainless steel and coated with epoxy r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com