Method for preparing mycoprotein by taking glycerin residue as raw material

A technology of bacterial protein and residue, which is applied in animal feed, animal feed, application, etc., can solve the problems of secondary pollution, increased cost investment, etc., and achieve the goal of reducing preparation cost, low cost, significant economic and social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

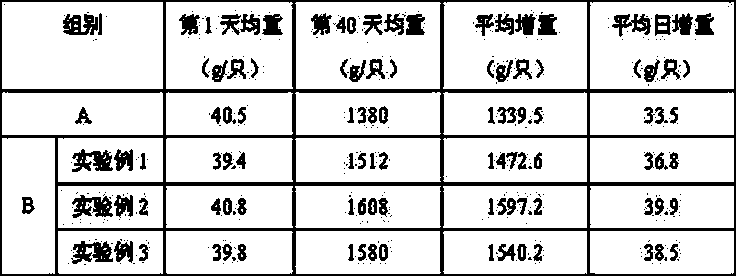

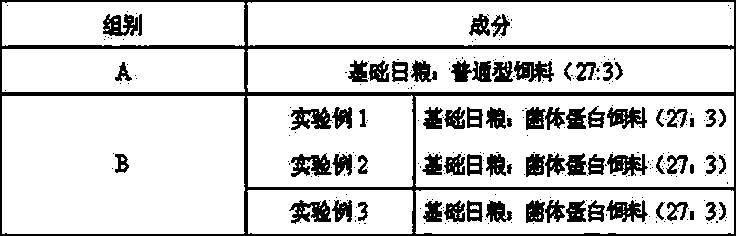

Embodiment 1

[0023] Embodiment 1 The method for preparing bacterial protein with glycerol residue as raw material

[0024] Take 80g of glycerin residue and dilute it with water to 400mL to prepare a glycerin residue dilution, add 1% peptone, 1% dipotassium hydrogen phosphate, 0.5% potassium dihydrogen phosphate, 0.05 % magnesium sulfate, 5% sodium chloride, after mixing evenly, adjust the pH value to 6.5 with hydrochloric acid. Distribute the culture medium into four 500 mL Erlenmeyer flasks with a liquid volume of 100 mL, and the remaining medium as seed culture medium into 50 mL Erlenmeyer flasks with a liquid volume of 10 mL, and autoclave at 121°C for 20 min to obtain the fermentation medium and seed medium.

[0025] Take 1% glucose, 0.5% peptone, 1% sodium chloride and 1.5% agar to make slant medium. Geotrichum candidum and Botrytis cinerea were selected and placed in the slant medium to cultivate the slant strains. The slant strains cultivated by Geotrichum candidum one-ring and...

Embodiment 2

[0029] Embodiment 2 is the method for raw material preparation bacterial protein with glycerol residue

[0030] Take 72 g of glycerin residue and dilute it to 400 mL with water to prepare a glycerin residue dilution, add 2% ammonium sulfate, 0.5% ammonium nitrate, and 1% dipotassium hydrogen phosphate to it, respectively. 0.5% potassium dihydrogen phosphate, 0.5% magnesium sulfate, 2.5% sodium chloride, after mixing evenly, adjust the pH value to 7 with hydrochloric acid. Distribute the medium into a 500 mL Erlenmeyer flask with a liquid volume of 100 mL, and the remaining medium as a seed medium into a 50 mL Erlenmeyer flask with a liquid volume of 10 mL, and autoclave at 121°C for 20 min. Fermentation medium and seed medium are obtained.

[0031] Take 2% glucose, 1% peptone, 1% sodium chloride and 1.5% agar to make slant medium. Candida tropicalis and Botrytis cinerea were selected and placed in the slant medium to cultivate the slant strains. Take one ring of Candida t...

Embodiment 3

[0035] Embodiment 3 is the method for raw material preparation bacterial protein with glycerol residue

[0036] Take 160g of glycerin residue and dilute it to 400ml with water to prepare a glycerin residue dilution, add yeast extract, 0.25% ammonium nitrate, 1% ammonium sulfate, 0.5% Sodium dihydrogen phosphate, 0.5% magnesium chloride, 1% sodium chloride, after mixing thoroughly, adjust the pH value to 7.5 with hydrochloric acid. Distribute the medium into a 500 mL Erlenmeyer flask with a liquid volume of 100 mL, and the remaining medium as a seed medium into a 50 mL Erlenmeyer flask with a liquid volume of 10 mL, and autoclave at 121°C for 20 min. Fermentation medium and seed medium are obtained.

[0037] Take 1.5% glucose, 0.75% peptone, 1% sodium chloride and 2% agar to make slant medium. Candida tropicalis and Geotrichum candidum were selected and placed in the slant medium to cultivate the slant strains. The slants cultured by two rings of Candida tropicalis and one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com