Preparation method of layer-by-layer self-assembled double-modified liposome

A layer-by-layer self-assembly and double-modification technology, applied in the fields of medicine, food, and cosmetics, can solve problems such as drug leakage, particle flocculation, and easy particle size increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

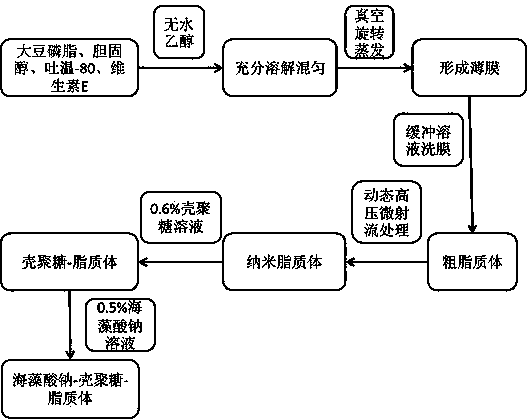

Method used

Image

Examples

Embodiment 1

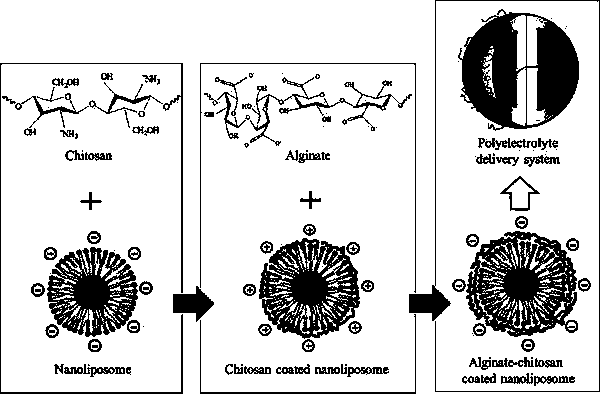

[0025] Weigh 0.206g of lecithin, 0.034g of cholesterol, 0.062g of Tween-80 and 0.004g of vitamin E, completely dissolve in 10ml of absolute ethanol, and remove the absolute ethanol by vacuum rotation in a water bath at 40°C to form a uniform film. Add 30ml of phosphate buffered saline (PBS) with pH7.4 and a concentration of 0.05M to wash the membrane, and the uniform suspension formed is the thick liposome. The crude liposomes were added into DHPM, and subjected to microfluidization treatment twice under the condition of 120 MPa to prepare nano liposomes. The prepared nano-liposome is a relatively transparent light blue solution, and the liposome solution is added dropwise to 0.6% chitosan (CH) solution while stirring, and its pH is adjusted to 5.5. After stirring for 1 hour, let stand for 1 hour to obtain chitosan-liposome (CH-L). Then CH-L was added dropwise to 0.5% sodium alginate (AL) solution while stirring, the pH of the solution was adjusted to 5.5, stirred for 1 hour,...

Embodiment 2

[0027] Weigh 0.411g of lecithin, 0.069g of cholesterol, 0.123g of Tween-80 and 0.008g of vitamin E, completely dissolve in 20ml of absolute ethanol, and remove the absolute ethanol by vacuum rotation in a water bath at 40°C to form a uniform film. Add 60ml of phosphate buffered saline (PBS) with pH7.4 and a concentration of 0.05M to wash the membrane, and the uniform suspension formed is the thick liposome. The crude liposomes were added into DHPM, and subjected to microfluidization treatment twice under the condition of 120 MPa to prepare nano liposomes. The prepared nano-liposome is a relatively transparent light blue solution, and the liposome solution is added dropwise to 0.6% chitosan (CH) solution while stirring, and its pH is adjusted to 5.5. After stirring for 1 hour, let stand for 1 hour to obtain chitosan-liposome (CH-L). Then CH-L was added dropwise to 0.5% sodium alginate (AL) solution while stirring, the pH of the solution was adjusted to 5.5, stirred for 1 hour,...

Embodiment 3

[0029]Weigh 0.206g of lecithin, 0.034g of cholesterol, 0.054g of Tween-80 and 0.006g of vitamin E, completely dissolve in 10ml of absolute ethanol, and remove the absolute ethanol by vacuum rotation in a water bath at 40°C to form a uniform film. Add 30ml of phosphate buffered saline (PBS) with pH7.4 and a concentration of 0.05M to wash the membrane, and the uniform suspension formed is the thick liposome. The crude liposomes were added into DHPM, and subjected to microfluidization treatment twice under the condition of 120 MPa to prepare nano liposomes. The prepared nano-liposome is a relatively transparent light blue solution, and the liposome solution is added dropwise to 0.6% chitosan (CH) solution while stirring, and its pH is adjusted to 5.5. After stirring for 1 hour, let stand for 1 hour to obtain chitosan-liposome (CH-L). Then CH-L was added dropwise to 0.5% sodium alginate (AL) solution while stirring, the pH of the solution was adjusted to 5.5, stirred for 1 hour, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com