Preparation method of nitrogen-doped mesoporous carbon-silica-based strongly acidic heterogeneous ionic liquid catalytic material

A silicon dioxide and ionic liquid technology, applied in the field of material science, can solve the problems of low catalytic efficiency, complicated preparation process, high cost, etc., achieve excellent catalytic performance, simple and effective method, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

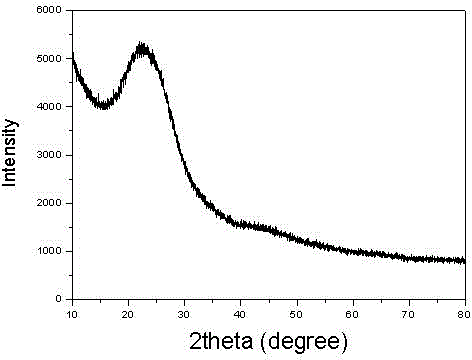

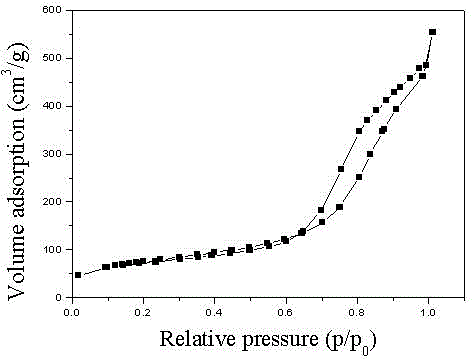

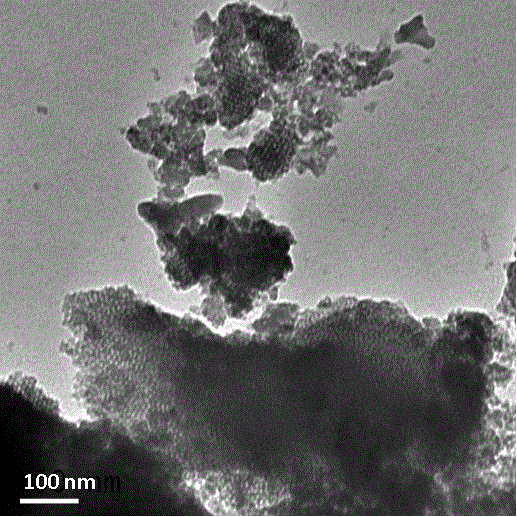

[0039] Firstly, using ethanol as solvent and F127 as template to synthesize nitrogen-doped mesoporous carbon-silica nanocomposite heterogeneous ionic liquid catalytic material, changing the nitrogen content.

[0040] Add 20g of absolute ethanol to 2.4g of F127 to dissolve, then add 20.4g (50%) of cyanamide aqueous solution, adjust the pH to about 2.0 with 1:1 hydrochloric acid, stir for 30 minutes, add 2.25mL of ethyl orthosilicate, and continue stirring After 3 hours, the solvent was evaporated at room temperature to obtain a white film, and baked at 100 degrees Celsius for 24 hours to obtain the primary product of nitrogen-doped mesoporous carbon-silica. The primary product obtained above is calcined at 600° C. for 3 hours under the protection of an inert gas to obtain a nitrogen-doped mesoporous carbon-silicon dioxide nanocomposite with open pores.

[0041] Functionalized ionic liquid: add 1 g of the material obtained above to 20 ml of toluene solution containing 1.0 g of 1,3...

Embodiment 2

[0046] Nitrogen-doped mesoporous carbon-silica nanocomposite heterogeneous ionic liquid catalytic materials were synthesized with methanol as solvent and F127 as template.

[0047] Add 10g of anhydrous methanol to dissolve 1.6g of F127, then add 10.2g (50%) of cyanamide aqueous solution, adjust the pH to about 2.0 with 1:1 hydrochloric acid, stir for 30 minutes, add 2.25mL of ethyl orthosilicate, and continue stirring After 3 hours, the solvent was evaporated at room temperature to obtain a white film, and baked at 140 degrees Celsius for 24 hours to obtain the primary product of nitrogen-doped mesoporous carbon-silica. The primary product obtained above is calcined at 800° C. for 3 hours under inert gas protection conditions to obtain carbonized nitrogen-silicon dioxide nanocomposites with open pores.

[0048] Functionalized ionic liquid: add 1 g of the material obtained above to 20 ml of toluene solution containing 0.8 g of 1,3-propane sultone, reflux at 100 degrees Celsius ...

Embodiment 3

[0050] Nitrogen-doped mesoporous carbon-silica nanocomposite heterogeneous ionic liquid catalytic materials were synthesized by using ethanol as solvent, P123 as template, and changing the synthesis temperature.

[0051] Add 10g of absolute ethanol to 2.0g P123 to dissolve, then add 10.2g (50%) cyanamide aqueous solution, adjust the pH to about 2.0 with 1:1 hydrochloric acid, stir for 30 minutes, add 2.25mL orthosilicate ethyl ester, continue stirring After 3 hours, the solvent was evaporated at room temperature to obtain a white film, and baked at 80 degrees Celsius for 24 hours to obtain the primary product of nitrogen-doped mesoporous carbon-silica. The primary product obtained above is calcined at 550° C. for 3 hours under the protection of an inert gas to obtain a nitrogen-doped mesoporous carbon-silicon dioxide nanocomposite with open pores.

[0052] Functionalized ionic liquid: add 1 g of the material obtained above to 20 ml of toluene solution containing 0.8 g of 1,3-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com