Preparation method of water-soluble upconversion fluorescence nano material

A fluorescent nanomaterial, water-soluble technology, applied in the direction of luminescent materials, nanotechnology, nano-optics, etc., can solve the problems of unsuitability for biological analysis, complicated pretreatment operation, large size, etc., to achieve a safe and non-toxic reaction process, suitable for The effect of mass production and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

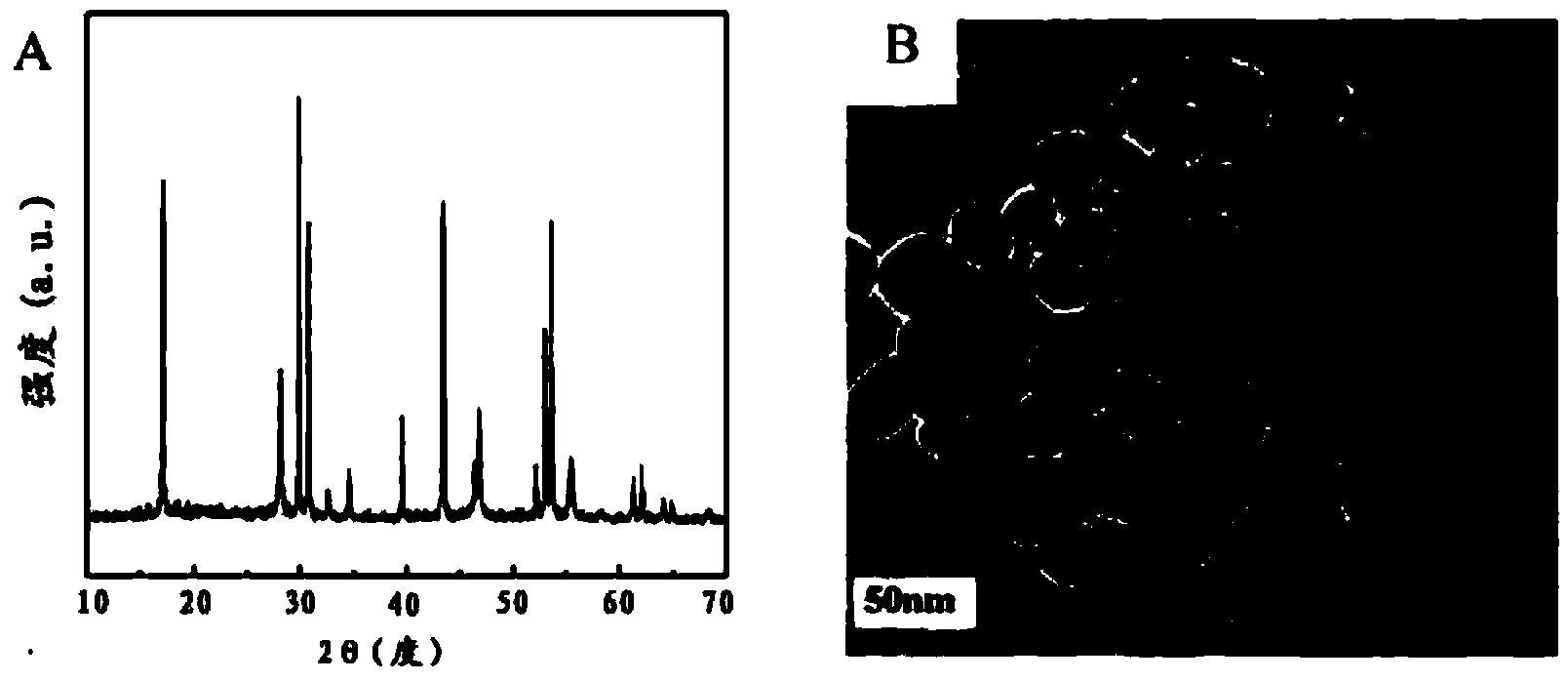

[0036] Take 2ml of rare earth nitrate solution (the mass of rare earth nitrate is 0.1458g, and the molar ratio of each rare earth ion is yttrium ion:ytterbium ion:erbium ion=80:18:2), add 12ml of absolute ethanol to it, and then add 0.9000 g polyacrylic acid (the mass ratio of rare earth nitrate to polyacrylic acid is 0.162:1) aqueous solution 14ml, stirred for 10min; then add 0.2100g sodium fluoride (F - / Ln 3+ Molar ratio of 10:1) aqueous solution 8ml, after stirring for 20min, put it in a high-pressure reactor, and react at 200°C for 10h under stirring condition; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, and use anhydrous Wash with ethanol and ultrapure water three times respectively, and vacuum-dry at room temperature for 12 hours to obtain a solid upconversion fluorescent material, and its X-ray diffraction spectrum (XRD) and transmission electron microscope (TEM) are as follows: figure 1 shown; figure 1 The X-...

Embodiment 2

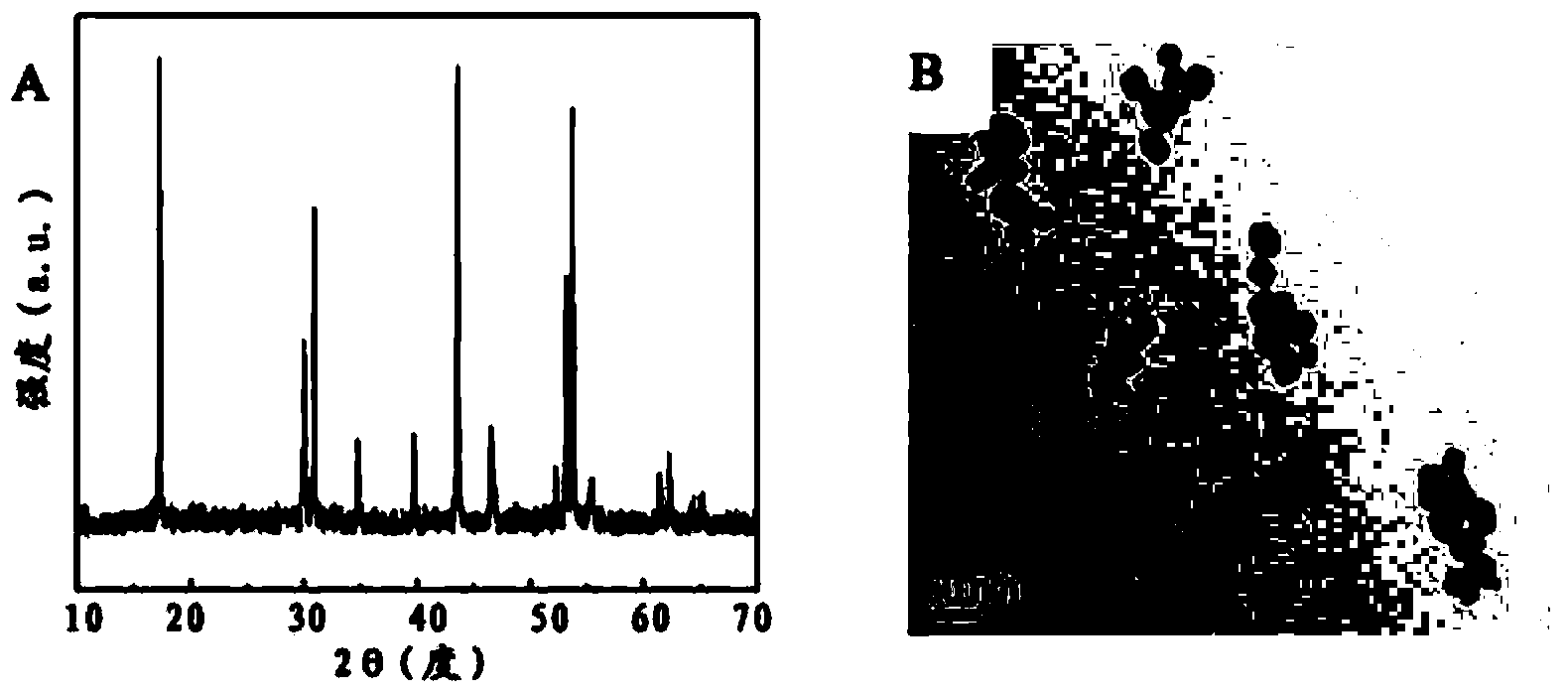

[0038] Take 2ml of rare earth nitrate solution (the mass of rare earth nitrate is 0.1458g, and the molar ratio of each rare earth ion is yttrium ion:ytterbium ion:erbium ion=80:18:2), add 18ml of absolute ethanol to it, and then add 0.9000 8ml of an aqueous solution of polyacrylic acid (the mass ratio of rare earth nitrate to polyacrylic acid is 0.162:1), stirred for 10min; then add 0.2100g of sodium fluoride (F - / Ln 3+ Molar ratio of 10:1) aqueous solution 8ml, after stirring for 20min, put it in a high-pressure reactor, and react at 200°C for 10h under stirring condition; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, and use anhydrous Wash with ethanol and ultrapure water three times respectively, and vacuum-dry at room temperature for 12 hours to obtain a solid upconversion fluorescent material, and its X-ray diffraction spectrum (XRD) and transmission electron microscope (TEM) are as follows: figure 2 shown; figu...

Embodiment 3

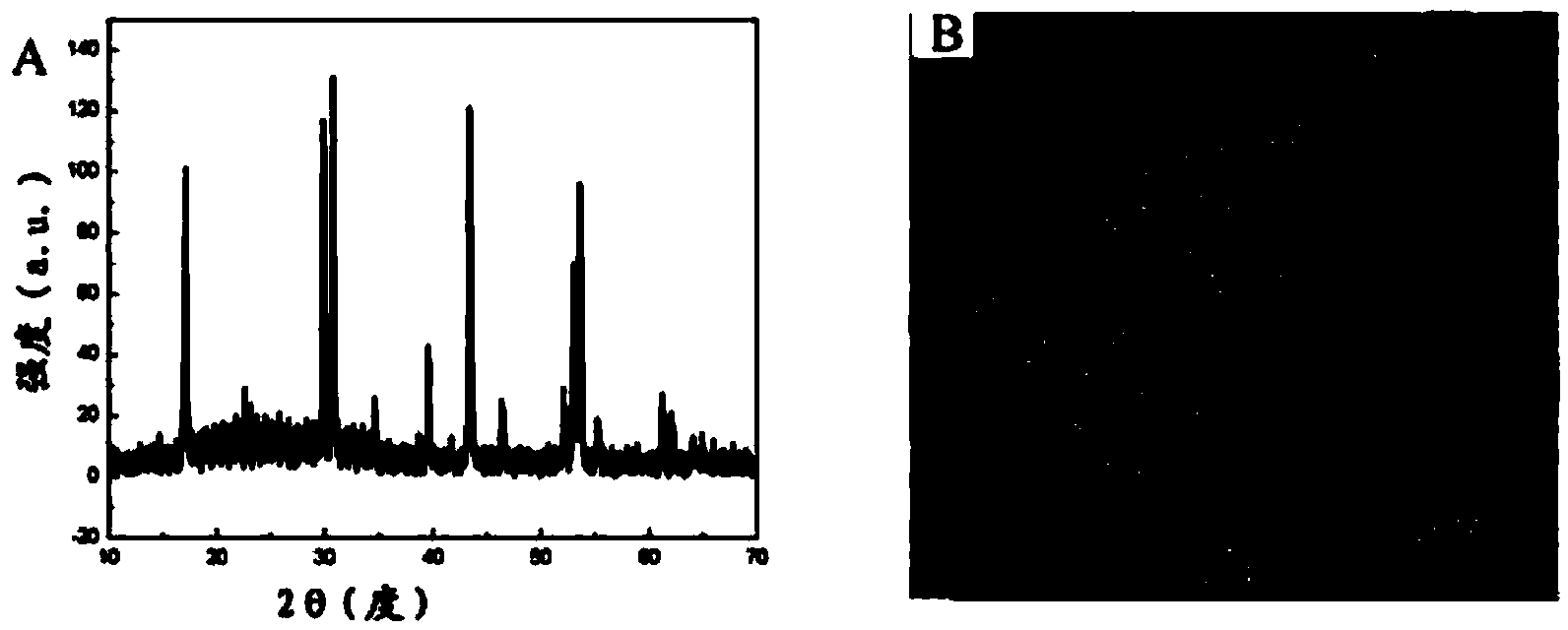

[0040] Take 2ml of rare earth nitrate solution (the mass of rare earth nitrate is 0.1458g, and the molar ratio of each rare earth ion is yttrium ion:ytterbium ion:erbium ion=80:18:2), add 18ml of absolute ethanol to it, and then add 0.3400 8ml of aqueous solution of polyethyleneimine (the mass ratio of rare earth nitrate to polyethyleneimine is 0.429:1), stirred for 10min; then add 0.1260g of sodium fluoride (F - / Ln 3+ Molar ratio of 6:1) aqueous solution 8ml, after stirring for 20min, put it in the autoclave, under the condition of stirring, hydrothermal reaction at 240℃ for 10h; stop heating and keep stirring to cool to room temperature, centrifuge to separate the solid product, use Wash each with absolute ethanol and ultrapure water 3 times, and vacuum-dry at room temperature for 12 hours to obtain a solid up-conversion fluorescent material. Its X-ray diffraction pattern (XRD) and transmission electron microscope pattern (TEM) are as follows: image 3 shown; image 3 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com