A kind of preparation method of superhydrophobic bismuth coating

A super-hydrophobic and coating technology, which is applied in the direction of coating, metal material coating process, and device for coating liquid on the surface, etc., can solve the problems of expensive, unfavorable environment, environmental hazards, etc., and achieve green production and reduce emissions and environmental pollution, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation method of superhydrophobic bismuth coating comprises the steps:

[0022] After the zinc flakes were cleaned by ultrasonic ethanol solvent, they were dried in the air and set aside. Add bismuth chloride to absolute ethanol, and obtain a 30mmol / L bismuth chloride ethanol solution by ultrasonic dispersion, then immerse the treated zinc sheet in the bismuth chloride ethanol solution, react at 25°C for 10min, take it out, and use After cleaning the surface with water and ethanol, dry it, then soak it in 20mmol / L stearic acid ethanol solution at room temperature for 30min, take it out, and obtain a superhydrophobic bismuth coating on the surface of the zinc sheet after drying.

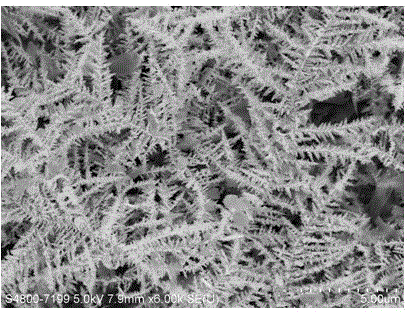

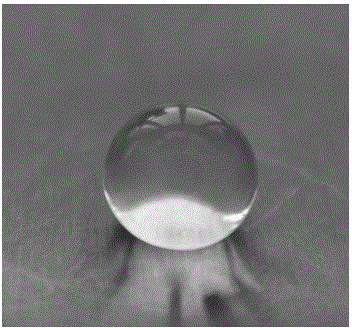

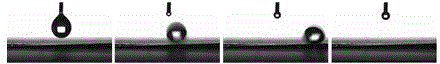

[0023] attached figure 1 It is a surface topography diagram of the bismuth coating in Example 1 observed by a Hitachi S224800 scanning electron microscope (SEM). It can be seen from the figure that the bismuth coating has a dendrite-like micron structure, the trunk of the branch is a...

Embodiment 2

[0027] The preparation method of superhydrophobic bismuth coating comprises the steps:

[0028] After the zinc flakes were cleaned by ultrasonic ethanol solvent, they were dried in the air and set aside. Add bismuth nitrate to isopropanol, ultrasonically disperse to obtain 5mmol / L bismuth nitrate isopropanol solution, then immerse the treated zinc sheet in bismuth nitrate isopropanol solution, react at 60°C for 20min, take out with Clean the surface with absolute ethanol and dry it, then soak it in 30mmol / L stearic acid ethanol solution at room temperature for 35min, take it out, and obtain a superhydrophobic bismuth coating on the surface of the zinc sheet after drying.

Embodiment 3

[0030] The preparation method of superhydrophobic bismuth coating comprises the steps:

[0031] After the zinc flakes were cleaned by ultrasonic ethanol solvent, they were dried in the air and set aside. Add bismuth iodide into n-butanol, and obtain 15mmol / L bismuth iodide n-butanol solution by ultrasonic dispersion, then immerse the treated zinc sheet in bismuth iodide n-butanol solution, and react at 10°C for 60min Take it out, clean the surface with absolute ethanol and dry it, then soak it in 50mmol / L palmitic acid ethanol solution at room temperature for 15min, take it out, and get a superhydrophobic bismuth coating on the surface of the zinc sheet after drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com