Potassium sodium dehydroandroan drographolide succinate enteric dry suspension and preparation method thereof

A technology of dry suspension, Yanhuning intestinal, which is applied in the field of Yanhuning enteric-coated dry suspension and its preparation, can solve the problems of patients' psychological and physiological resistance, poor medication compliance, etc., and reduce the incidence of adverse reactions , fast onset, guaranteed curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Yanhuning enteric-coated pellets or granule prescription preferred

[0041] 1) Selection of Yanhuning drug-loaded pellets or drug-loaded granules

[0042] Weigh the raw and auxiliary materials of the following prescription quantities, pass through 120 meshes respectively, mix well, and prepare drug-loaded pellets with different binders by using a centrifugal granulator. Observe the pelleting situation. The results are shown in Table 1.

[0043] Table 1 Screening Results

[0044]

[0045] The test results showed that prescription 5 had the best pill-making effect, that is, when microcrystalline cellulose was used as filler, micronized silica gel was used as glidant, and 40% ethanol was used as binder, the pill-making effect was the best.

[0046] 2) Yanhuning enteric-coated pellets or granules enteric-coated layer coating prescription is preferred

[0047] According to the above-mentioned optimal prescription (prescription 5), the raw and auxiliary mate...

Embodiment 2

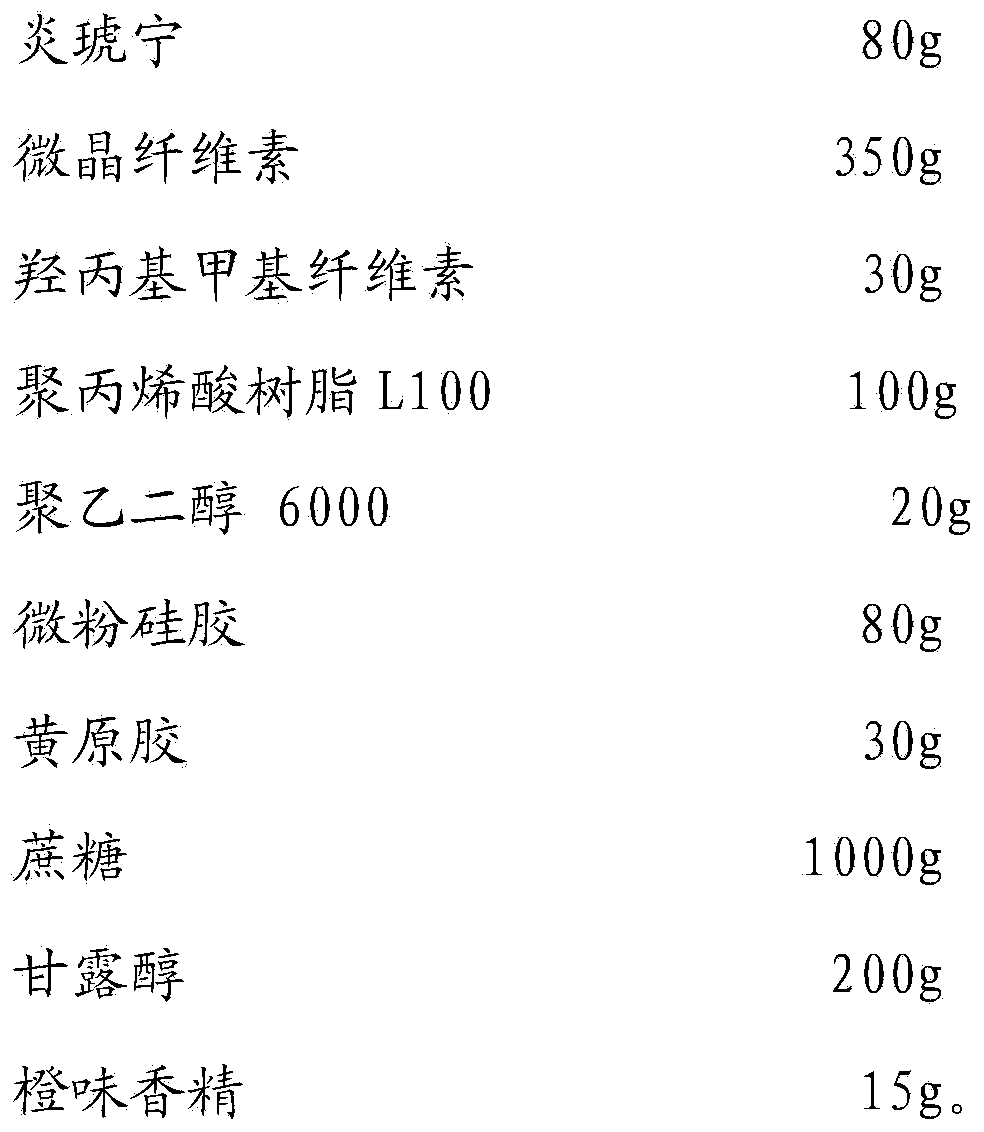

[0056] In this example, 1000 bags of Yanhuning enteric-coated dry suspension were prepared, and the following prescription was adopted:

[0057]

[0058] Preparation Process:

[0059] (1) Mix 120 mesh sieves of Yanhuning and microcrystalline cellulose and micropowder silica gel of the prescribed quantity, and set aside; prepare 40% ethanol solution for subsequent use; adopt a centrifugal granulator, use the above-mentioned 40% ethanol solution as Prepare drug-loaded pellets (with a particle size of 80 mesh to 100 mesh) with the binder, control the temperature at 37°C to 40°C, and spray the liquid at a flow rate of 0.5 to 1ml / min. Dry in an oven at 40°C after the drug application is complete;

[0060] (2) Place the dried Yanhuning pellets in a fluidized bed coating machine, and use 5% hydroxypropyl methylcellulose aqueous solution as the coating solution to coat the isolation layer. Main engine parameters Speed: 120~200rpm; Spray liquid: 3~10rpm; Air volume: small; Atomiza...

Embodiment 3

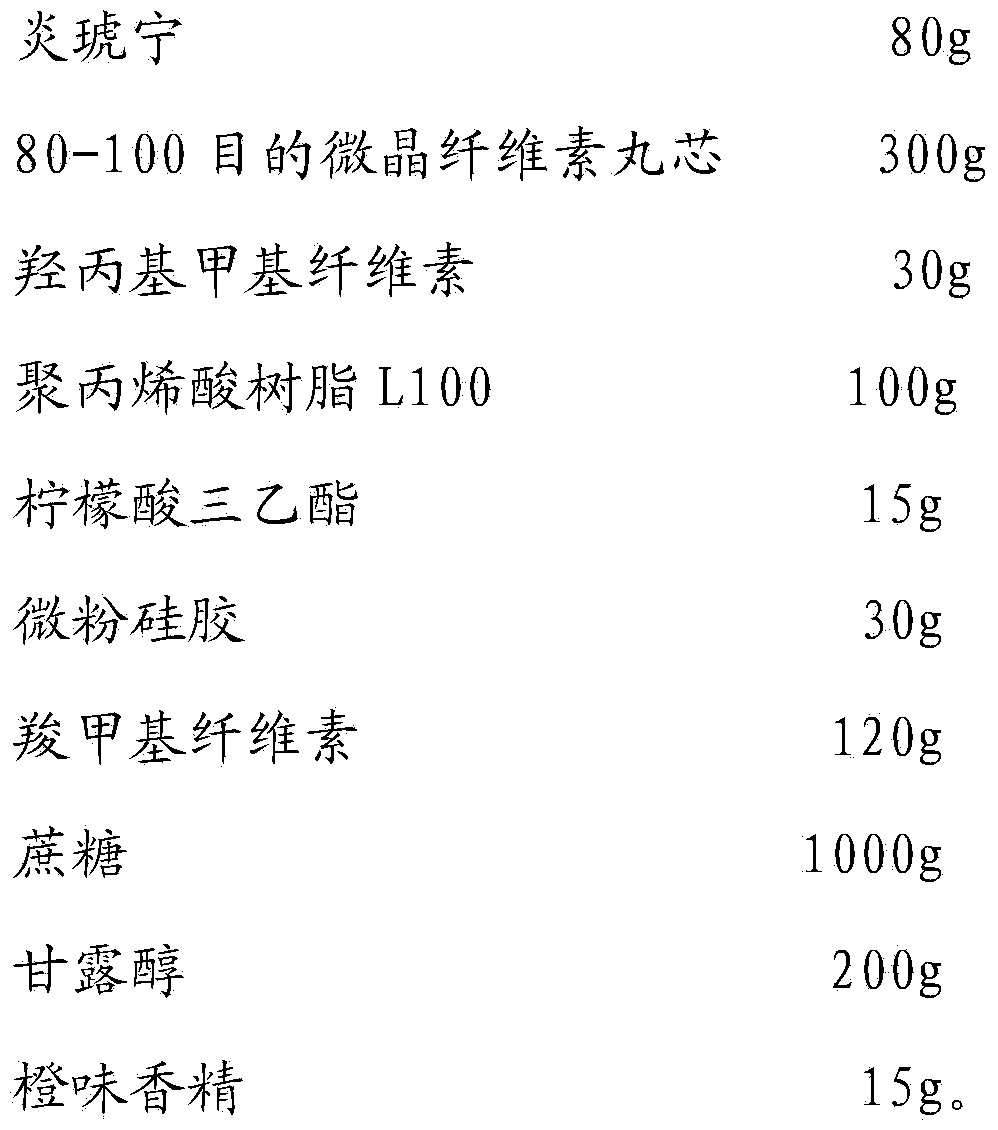

[0064] In this example, 1000 bags of Yanhuning enteric-coated dry suspension were prepared, and the following prescription was adopted:

[0065]

[0066] Preparation Process:

[0067] (1) Mix the prescribed amount of Yanhuning and the prescribed amount of micropowder silica gel through a 120 mesh sieve, and set aside; prepare 60% ethanol solution for later use; place the microcrystalline cellulose ball core in a centrifugal granulator, and use the above 60 The % ethanol solution is used as the adhesive for drug application, the temperature is controlled at 37°C-40°C, and the spray flow rate is 0.5-1ml / min. Dry in an oven at 40°C after the drug application is complete;

[0068] (2) Place the dried Yanhuning pellets in a fluidized bed coating machine, and use 5% hydroxypropyl methylcellulose aqueous solution as the coating solution to coat the isolation layer. Main engine parameters Speed: 120~200rpm; Spray liquid: 3~10rpm; Air volume: small; Atomization pressure: 0.05~0.1m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com