Xanthoceraside preparation method

A technology of sorbiflorin and sorbifolin, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

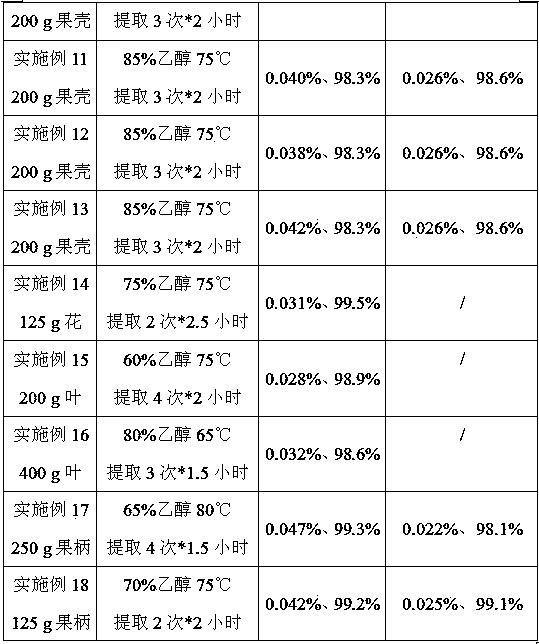

Examples

Embodiment 1

[0031] Take 100 g of Xantho sorbifolia husks crushed into 20 meshes, use 10 times the volume of 50% ethanol at a volume percentage concentration of 65°C, heat and reflux for 3 times for 3 hours / time, recover the solvent, and concentrate to obtain a crude extract , the crude extract is separated and purified by normal-phase silica gel column chromatography with a mesh number of 100-200, and is eluted with chloroform-methanol or dichloromethane-methanol with a volume ratio of 7:1 and 2:1 respectively , heating to reflux, recovering the solvent under reduced pressure, enriching to obtain the xanthoside fraction, placing it at room temperature, using methanol-water solvent system for recrystallization, and obtaining refined high-purity xanthoside after repeated recrystallization; the purity is 99.5%, the yield is 0.047% 0 .

[0032] According to the method of the previous patent (publication number: CN1626545, authorized announcement number: CN1281616C), 100 g of Xantho sorbifoli...

Embodiment 2

[0034] Take 150 g of radix sorbifolia husks crushed into 30 meshes, use 8 times the volume of 70% ethanol, temperature 70°C, heat and reflux for extraction, time 2 hours / time, extract twice, heat and reflux, and recover the solvent under reduced pressure , the extract obtained after concentration is separated and purified by normal-phase silica gel column chromatography with a mesh number of 200-300, and chloroform-methanol or dichloromethane-methanol with a volume ratio of 8:1 and 3:1 is used as the eluting solvent Elution, recovery of the solvent under reduced pressure, enrichment to obtain the fraction of xanthosides, and crude saponins; recrystallization with methanol, repeated recrystallization to obtain refined high-purity xanthosides; the purity is 98.9%, The yield is 0.048% 0 .

[0035] According to the method of the previous patent (publication number: CN1626545, authorization announcement number: CN1281616C), 150 g of Xantho sorbifolia husks were also crushed into 3...

Embodiment 3

[0037] Take 150 g of radix sorbifolia husks crushed into 30 meshes, use 8 times the volume of 65% ethanol, temperature 70°C, heat and reflux extraction, time 2.5 hours / time, extract 3 times, heat and reflux, and reduce pressure to recover the solvent , the extract obtained after concentration is separated and purified by normal-phase silica gel column chromatography with a mesh number of 200-300, and chloroform-methanol or methylene chloride-methanol with a volume ratio of 7:1 and 3:1 is used as the eluting solvent Elution, recovery of the solvent under reduced pressure, enrichment to obtain the fraction of xanthosides, and crude saponins; recrystallization with methanol, repeated recrystallization to obtain refined high-purity xanthosides; the purity is 98.9%, The yield is 0.051% 0 .

[0038] According to the method of the previous patent (publication number: CN1626545, authorization announcement number: CN1281616C), 150 g of Xantho sorbifolia husks were also crushed into 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com