Low-pressure mercury electric-discharge lamp and ultraviolet disinfection and sterilization device

A technology of discharge lamps and ultraviolet lamps, which is applied to low-pressure discharge lamps, parts of gas discharge lamps, and light water/sewage treatment, etc., which can solve problems such as difficult to guarantee consistency, reduce lamp manufacturing costs, and reduce efficiency, and achieve improved Lamp current density, high output power, and system cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0104] Correspondingly, the present invention also provides a method for preparing the indium-mercury alloy or indium-mercury multi-element alloy in the low-pressure mercury discharge lamp, which can be made by a one-step melting alloy method, including: The various components are mixed according to the mass ratio, heated and melted to produce indium mercury alloy or indium mercury alloy.

[0105] Among them, indium mercury alloy or indium mercury multiple alloy can be placed in the exhaust pipe, or indium mercury alloy or indium mercury multiple alloy can be poured into the lamp after exhaust, or indium mercury alloy or indium mercury multiple alloy can be melted and fixed On the inner wall of the glass tube.

[0106] The preparation method of the indium-mercury alloy or indium-mercury multi-element alloy can also be made by a step-by-step melting alloy method, including: mixing metals other than mercury in a mass ratio, placing them in a sealed cavity of a low-pressure mercury di...

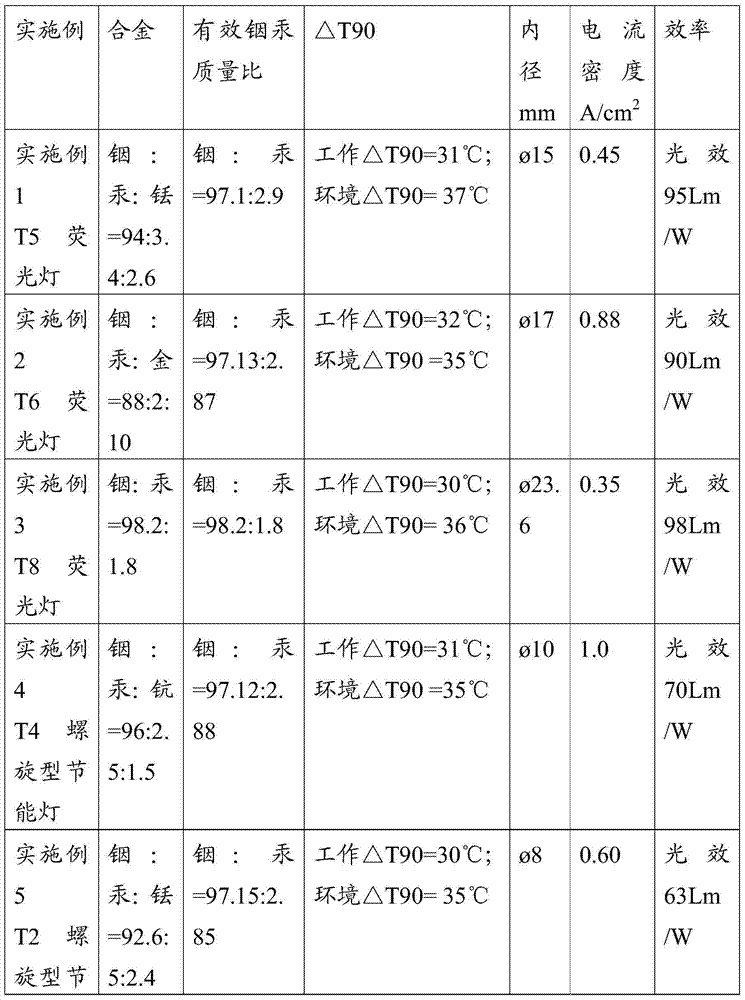

Embodiment 1

[0110] Example 1: T5 (inner diameter ) Fluorescent lamp length 1.2m, power 90W, lamp current 0.8A, tube current density 0.45A / cm 2 , The indium thulium alloy sheet is fixed on the front end of the electrode. After adding mercury, an indium thulium mercury ternary alloy is formed, in which indium: mercury: thulium = 94: 3.4: 2.6, and the effective mass ratio of indium to mercury is indium: mercury = (94.0- 3.4*2.04): 2.6=97.1:2.9. The phosphor is a rare earth three-primary phosphor with high temperature resistance and low light decay, with a light efficiency of 95Lm / W. It is used in low temperature environments such as freezing workshops and has strong environmental temperature adaptability. Compared with the traditional T5-28W fluorescent lamp, it not only solves the low temperature light output and low efficiency of the lamp, but also greatly improves the light output of a single lamp. One lamp can replace the traditional three lamps and reduce the rare earth three. The amount...

Embodiment 2

[0111] Example 2: T6 (inner diameter ) Fluorescent lamp length 1.2m, power 220W, lamp current 2.0A, tube current density 0.88A / cm 2 , The indium thulium alloy sheet is fixed on the front end of the electrode, and mercury is added to form an indium thulium mercury ternary alloy, where indium: mercury: thulium = 88:2:10, and the phosphor is a high-temperature resistant, low light decay rare earth three-primary fluorescence Powder, light effect 90Lm / W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com