Preparation method for modified lithium cobalt oxide capable of being recycled at high cut-off voltage

A unique technology of lithium cobalt oxide and cut-off voltage, applied in the field of preparation of modified lithium cobalt oxide, can solve the problems of poor cycle performance of lithium cobalt oxide, excessive delithiation of lithium cobalt oxide, deterioration of structural stability, etc. Cycle performance, inhibition of dissolution, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

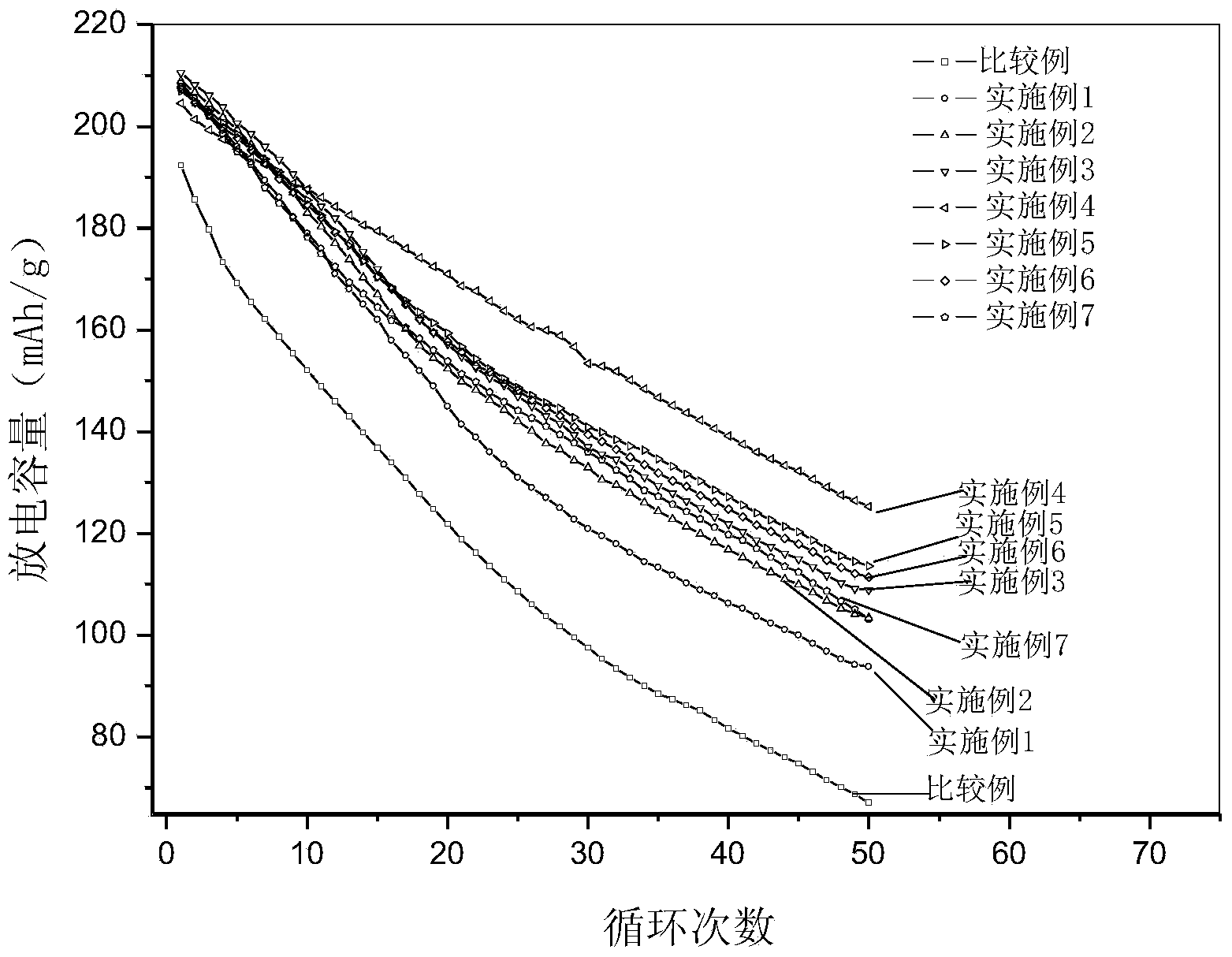

Embodiment 1

[0026] Mix 0.95mol cobalt sulfate and 0.05mol manganese sulfate to make 1000ml mixed solution; make ammonia water and 2M sodium hydroxide solution according to volume ratio 1:10 to make mixed solution 1100ml. Add the above two solutions into a 5L reactor at the same rate of 3.0ml / min, control the reaction temperature to 55°C, control the pH value to 11.5, and keep stirring until the addition is complete, and continue to stir for 0.5 hours. The obtained dark brown precipitate was filtered, washed with deionized water, and dried to obtain a manganese-doped cobalt oxyhydroxide precursor. The above precursor and lithium carbonate were uniformly mixed according to the molar ratio of Li and (Co+Mn) of 1.04:1, calcined at 1000°C for 10 hours, cooled and ground to obtain a semi-finished product of lithium cobaltate; The silicon oxide is mixed evenly, calcined at 900°C for 10 hours, cooled and ground to obtain the final modified lithium cobaltate product. In the voltage range of 3.0V ...

Embodiment 2

[0028] Mix 0.95mol cobalt sulfate and 0.05mol manganese sulfate to make 1000ml mixed solution; make ammonia water and 2M sodium hydroxide solution according to volume ratio 1:10 to make mixed solution 1100ml. Add the above two solutions into a 5L reactor at the same rate of 3.0ml / min, control the reaction temperature to 55°C, control the pH value to 11.5, and keep stirring until the addition is complete, and continue to stir for 0.5 hours. The obtained dark brown precipitate was filtered, washed with deionized water, and dried to obtain a manganese-doped cobalt oxyhydroxide precursor. The above precursor and lithium carbonate were uniformly mixed according to the molar ratio of Li and (Co+Mn) of 1.04:1, calcined at 1000°C for 10 hours, cooled and ground to obtain a semi-finished product of lithium cobaltate; the obtained semi-finished product and its mass of 0.5% magnesium oxide Mix evenly, calcinate at 900°C for 10 hours, cool and grind to obtain the final modified lithium co...

Embodiment 3

[0030] Mix 0.95mol cobalt sulfate and 0.05mol manganese sulfate to make 1000ml mixed solution; make ammonia water and 2M sodium hydroxide solution according to volume ratio 1:10 to make mixed solution 1100ml. Add the above two solutions into a 5L reactor at the same rate of 3.0ml / min, control the reaction temperature to 55°C, control the pH value to 11.5, and keep stirring until the addition is complete, and continue to stir for 0.5 hours. The obtained dark brown precipitate was filtered, washed with deionized water, and dried to obtain a manganese-doped cobalt oxyhydroxide precursor. The above precursor and lithium carbonate were uniformly mixed according to the molar ratio of Li and (Co+Mn) of 1.04:1, calcined at 1000°C for 10 hours, cooled and ground to obtain a semi-finished product of lithium cobaltate; the obtained semi-finished product and its mass of 0.5% alumina Mix evenly, calcinate at 900°C for 10 hours, cool and grind to obtain the final modified lithium cobaltate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com