Method for covering surface of gypsum type material with calcium carbonate

A technology of surface coating and calcium carbonate, which is applied in the chemical and chemical industry, can solve the problems of hindering the resource utilization of phosphogypsum, difficult unification of pretreatment methods, and large investment, and achieve the goal of improving application value, simple preparation process, and broad application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

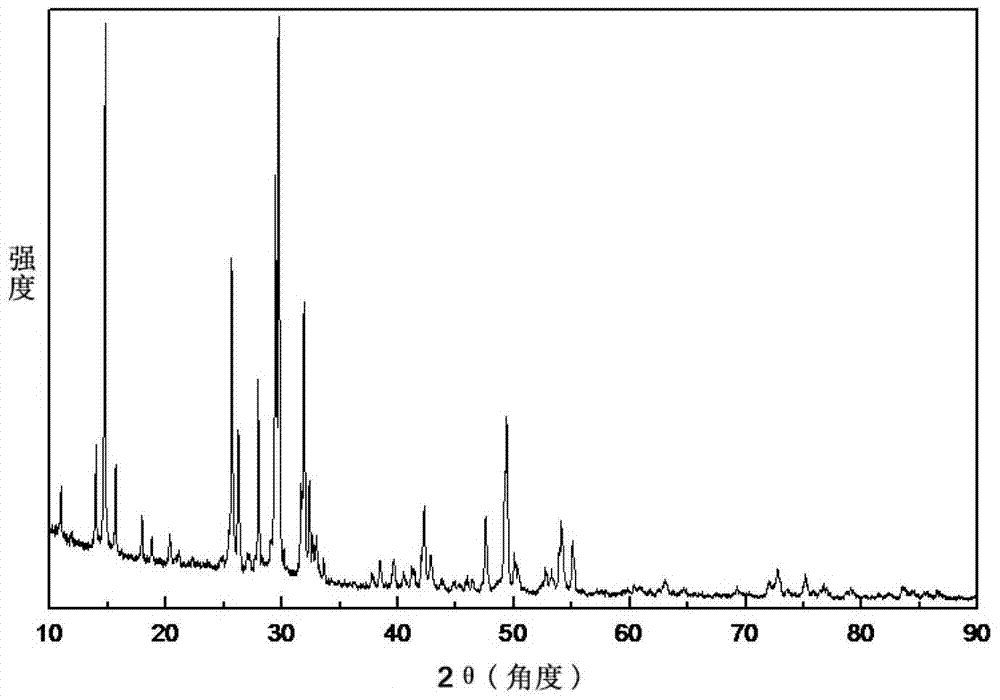

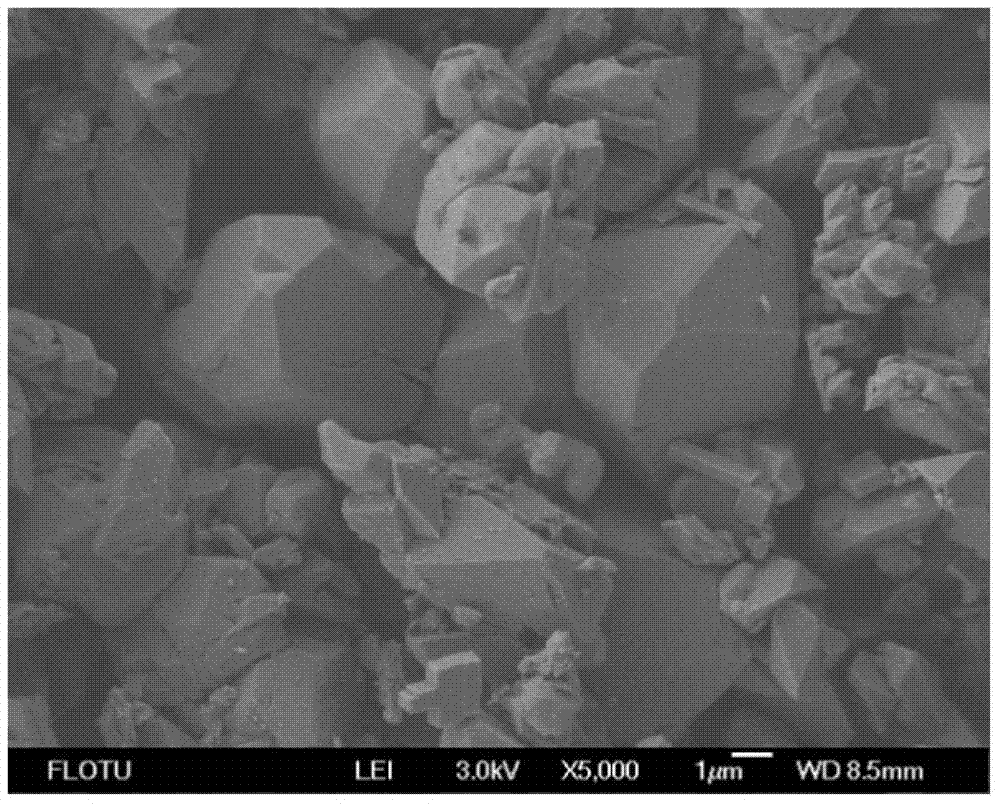

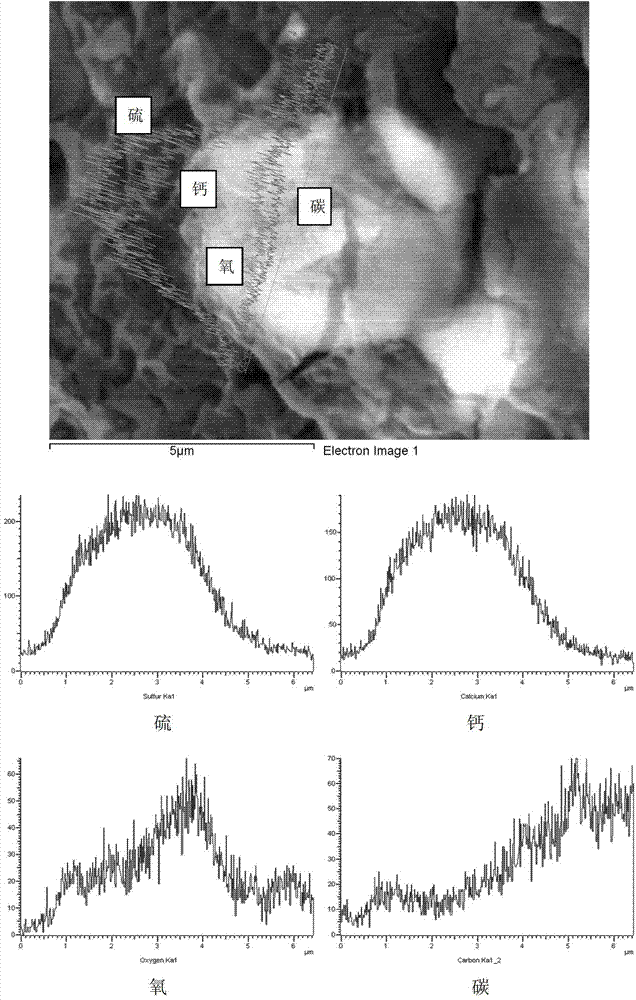

[0021] 8.61g CaSO 4 .2H 2 O and 0.39g of ammonium carbonate were put into the reaction kettle respectively, put in 120 ℃ of ovens and reacted for 24 hours, took out the reaction kettle and let it cool, and obtained the composite material of calcium carbonate coating calcium sulfate hydrate after the sample was taken out and dried. The X-ray diffraction pattern, electron microscope photo and scanning electron microscope energy spectrum line scan pattern of the composite material are respectively figure 1 , figure 2 and image 3 shown.

Embodiment 2

[0023] 1.72g CaSO 4 .2H 2 0 and 0.40g ammonium bicarbonate were put into the reaction kettle respectively, put in 100 ℃ of ovens and reacted for 20 hours, took out the reaction kettle and let it cool down, and obtained the composite material of calcium carbonate coating calcium sulfate hydrate after the sample was taken out and dried.

Embodiment 3

[0025] 4.30g CaSO 4 .2H 2 O and 0.39g of ammonium carbonate were put into the reaction kettle respectively, put in 120 ℃ of ovens and reacted for 24 hours, took out the reaction kettle and let it cool, and obtained the composite material of calcium carbonate coating calcium sulfate hydrate after the sample was taken out and dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com