In-situ ultrasonic polymerization preparation method for industrial alkali lignin modified phenolic resin

A technology of industrial alkali lignin and phenolic resin, which is used in the joining of wooden veneers, aldehyde/ketone condensation polymer adhesives, manufacturing tools, etc. The effect of simple control and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

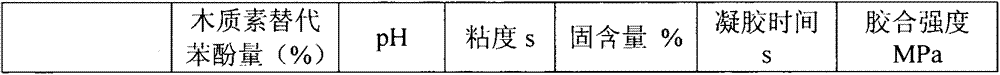

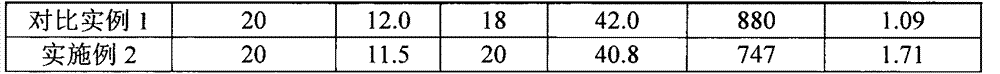

Examples

Embodiment 1

[0022] Weigh 500g of wheatgrass alkali lignin powder into a beaker, add 4500g of water, adjust the pH to 12 with 10% sodium hydroxide solution, and centrifuge to get the supernatant. Then add sulfuric acid solution with a mass concentration of 10% to adjust the pH value to 2, react at 75° C. for 30 minutes, centrifuge, and the precipitate is vacuum-dried to constant weight after repeated washing to obtain purified alkali lignin.

[0023] Weigh 20g of purified alkali lignin, 80g of phenol, 32g of formaldehyde solution with a mass concentration of 37%, and 129g of NaOH solution with a mass concentration of 20%. The power is 600W, and the ultrasonic time is 10min; transfer the reaction solution into a 500ml four-necked flask, start stirring, and heat up to 85°C within 45min, and react for 17min; cool the reaction solution below 50°C, and add 135g of 37% For formaldehyde solution, heat up to 85°C within 50 minutes, and react for 15 minutes; cool the reaction solution to 70°C, reac...

Embodiment 2

[0025] Weigh 500g of wheatgrass alkali lignin powder into a beaker, add 4500g of water, adjust the pH to 12 with 10% sodium hydroxide solution, and centrifuge to get the supernatant. Then add sulfuric acid solution with a mass concentration of 10% to adjust the pH value to 2, react at 75° C. for 30 minutes, centrifuge, and the precipitate is vacuum-dried to constant weight after repeated washing to obtain purified alkali lignin.

[0026] Weigh 20g of purified alkali lignin, 80g of phenol, 32g of formaldehyde solution with a mass concentration of 37%, and 129g of NaOH solution with a mass concentration of 20%. The power is 750W, and the ultrasonic time is 10min; transfer the reaction solution into a 500ml four-neck flask, start stirring, and heat up to 85°C within 45min, and react for 17min; cool the reaction solution below 50°C, and add 135g of 37% For formaldehyde solution, heat up to 85°C within 50 minutes, and react for 15 minutes; cool the reaction solution to 70°C, react ...

Embodiment 3

[0028] Weigh 500g of wheatgrass alkali lignin powder into a beaker, add 4500g of water, adjust the pH to 12 with 10% sodium hydroxide solution, and centrifuge to get the supernatant. Then add sulfuric acid solution with a mass concentration of 10% to adjust the pH value to 2, react at 75° C. for 30 minutes, centrifuge, wash the precipitate with water, and then vacuum-dry to constant weight to obtain purified alkali lignin.

[0029] Weigh 20g of purified alkali lignin, 80g of phenol, 32g of formaldehyde solution with a mass concentration of 37%, and 129g of NaOH solution with a mass concentration of 20%. The power is 900W, and the ultrasonic time is 10min; transfer the reaction solution into a 500ml four-necked flask, start stirring, and heat up to 85°C within 45min, and react for 17min; cool the reaction solution below 50°C, and add 135g of 37% For formaldehyde solution, heat up to 85°C within 50 minutes, and react for 15 minutes; cool the reaction solution to 70°C, react for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com