Sandwich type graphene saturable absorber and preparation method thereof

A sandwich type, graphene technology, applied in laser parts, electrical components, lasers, etc., can solve the problems of complex, expensive, complicated experimental equipment, etc., and achieve the effect of short recovery time, low saturation intensity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

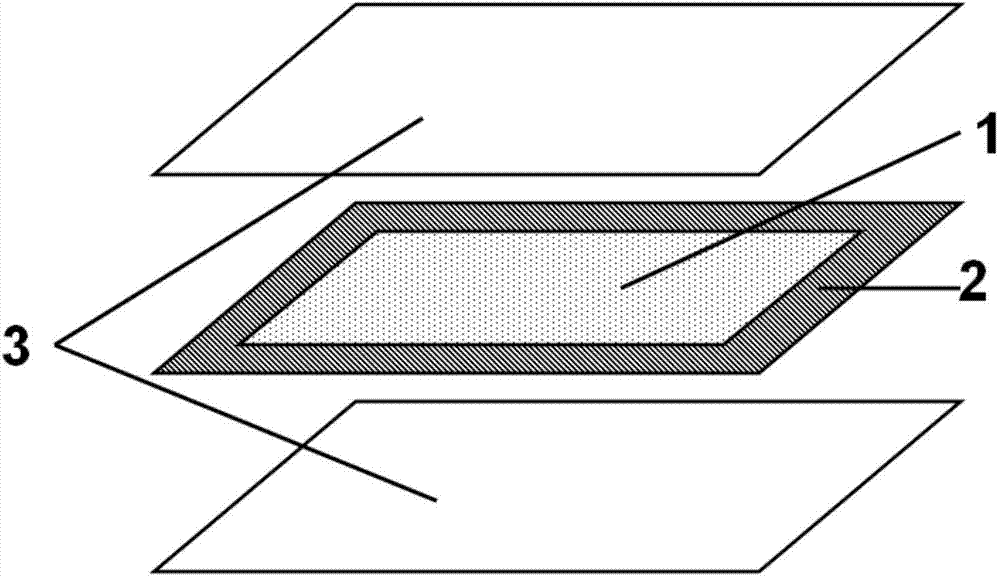

[0028] A preparation method of a sandwich type graphene saturated absorber, comprising the following steps:

[0029] (1) Prepare single-layer graphene on Cu foil by CVD method. The specific operation is: place the Cu foil in the constant temperature zone of the quartz tube, and seal the quartz tube completely; use a vacuum pump to pump the air pressure in the quartz tube to the limit vacuum state3 ×10 -6 At the same time, the temperature was raised to the growth temperature of 1050°C; after reaching the growth temperature, 50 sccm of hydrogen gas was introduced for annealing for 30 minutes, and then 50 sccm of methane gas was introduced; after 50 min of growth, the carbon source gas was turned off and the temperature was rapidly lowered under the hydrogen atmosphere.

[0030] (2) The graphene was transferred to the glass substrate by wet transfer technology. The specific operation was: cut the Cu foil deposited with graphene into a 15 mm × 15 mm square, and evenly rotate it on...

Embodiment 2

[0034] A preparation method of a sandwich type graphene saturated absorber, comprising the following steps:

[0035] (1) Prepare single-layer graphene on Cu foil by CVD method. The specific operation is: place the Cu foil in the constant temperature zone of the quartz tube, and seal the quartz tube completely; use a vacuum pump to pump the air pressure in the quartz tube to the limit vacuum state 2 ×10 -6 At the same time, the temperature was raised to the growth temperature of 1000°C; after reaching the growth temperature, 50 sccm of hydrogen gas was introduced for annealing for 30 minutes, and then 50 sccm of methane gas was introduced; after 50 min of growth, the carbon source gas was turned off and the temperature was rapidly cooled under the hydrogen atmosphere.

[0036] (2) Transfer the graphene to the glass substrate by using the wet transfer technique. The specific operation is: cut the Cu foil deposited with graphene into a 20 mm × 20 mm square, and evenly spin on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com