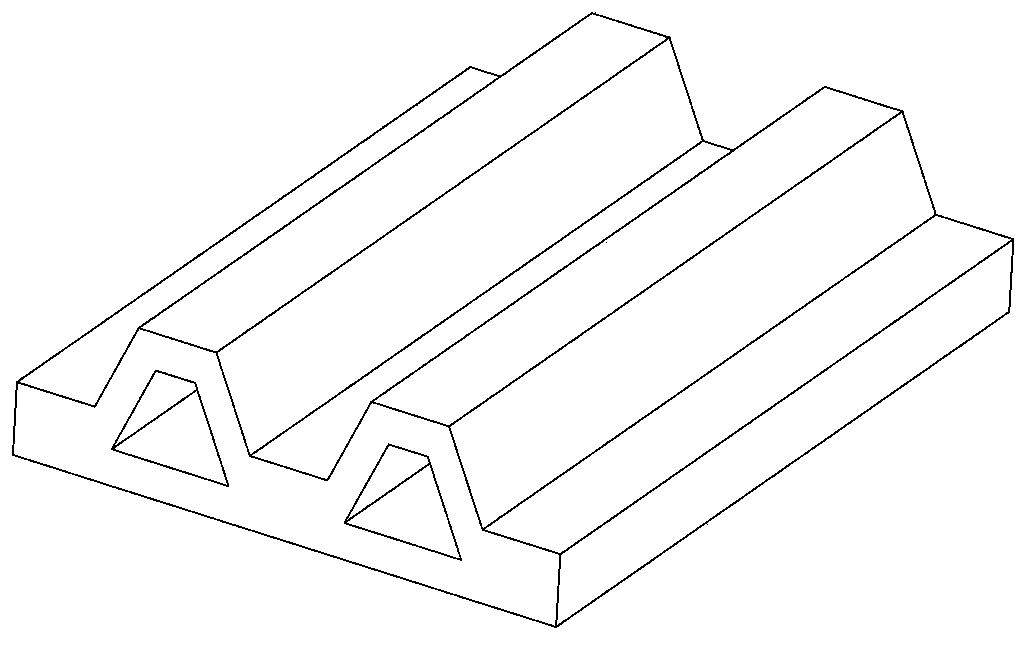

Corrugated hollow plate and manufacturing method thereof

A production method and hollow technology, applied in the direction of sheets/boards, flat products, other household appliances, etc., can solve the problems that cannot be popularized, the mechanical properties are not strong enough, and the cost is high, so as to reduce the mold cost, low price, and molding cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

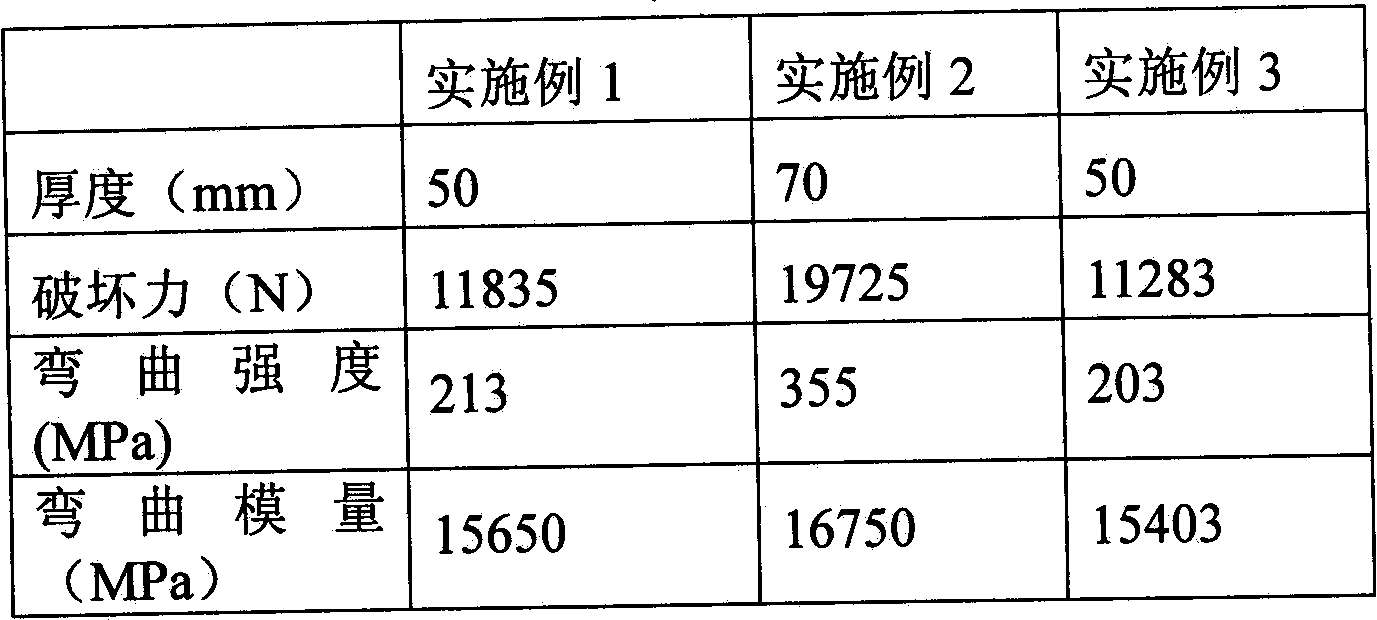

Embodiment 1

[0032] Continuous Glass Fiber Reinforced Polypropylene Hollow Panel

[0033] In this example, continuous glass fiber reinforced polypropylene is selected as the raw material, and the specification of the corrugated hollow board is 2400mm*1500mm*50mm, and the prepreg is cut according to the specification. Lay in the way of 0° / 90°, the thickness of the prepreg laid is 15mm, place the inflatable fluorinated phosphorus nitrile rubber mandrel treated with the release agent on the prepreg, and inflate the mandrel, The inflation pressure is 0.05MPa, and then fixed. In order to prevent the mandrel from slipping during fixing, relative fixing fixtures can be made according to the hole distance. After fixing, the 15mm prepreg is laid at 0° / 90°. The mold is then placed and moved into a heat press.

[0034] There are two upper and lower templates of the laminator, and the heating temperature of the two templates is: 190°C, and the molds are closed without pressure for preheating. After ...

Embodiment 2

[0036] Continuous glass fiber reinforced polyamide corrugated sheet

[0037] In this example, continuous glass fiber-reinforced polyamide is selected as the raw material, and the specification of the corrugated board is 2600mm*1500mm*70mm, and the prepreg is cut according to the specification. Lay in the way of 0° / 90°, the thickness of the prepreg laid is 20mm, place the inflatable perfluoroether rubber mandrel treated with the release agent on the prepreg, inflate the mandrel, inflate The pressure is 0.05Mpa, and then fixed. In order to prevent the mandrel from slipping during fixing, you can make relative fixing fixtures according to the hole distance and fix them. Finally, lay 20mm prepreg in the way of 0° / 90°, and then place the mold , into a heat press.

[0038] There are two upper and lower templates of the laminator, and the heating temperature of the two templates is: 230°C, and the molds are closed without pressure for preheating. After preheating for 5-10 minutes, ...

Embodiment 3

[0040] A method for manufacturing a corrugated hollow plate, comprising the following steps:

[0041] (1) After the continuous basalt fiber is stretched by mechanical rolling, it is extruded through the staggered openable double extrusion die set to add polyethylene resin with anti-ultraviolet absorber and flame retardant, and the fiber bundle is infiltrated and compounded The continuous fibers impregnated with thermoplastic resin are obtained, and then roll-formed, and the tape-shaped prepreg is made by winding and curling the roll;

[0042] (2) Cut the strip-shaped prepreg according to the process requirements, and lay it at 0° / 90° according to the direction of the continuous fibers in the prepreg;

[0043] (3) Put an inflatable mandrel sprayed with a solvent-based silicon-based release agent in the middle layer of the laid prepreg, and inflate and fix the mandrel. The inflatable mandrel used is perfluoroalkyl Triazine rubber mandrel, the inner membrane material of the infl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com