Isotatic polypropylene-b-polyethylene glycol double block copolymer and preparation method thereof

A technology of isotactic polypropylene and polyethylene glycol, applied in the field of polypropylene modification, can solve problems such as difficult industrialization, difficult industrial application, and controllability, and achieve the effect of easy industrial production, easy realization, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

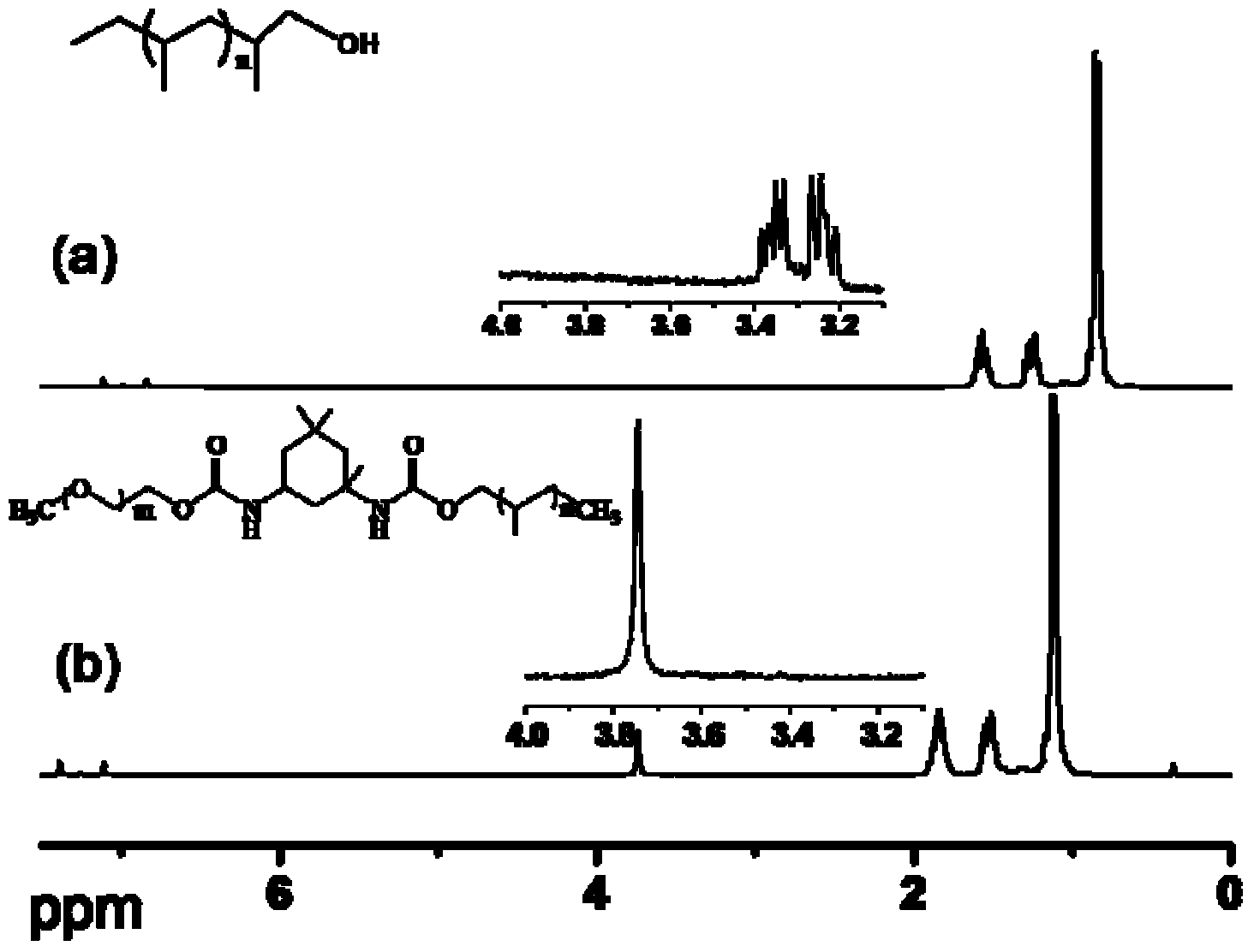

[0025] 1. Preparation of isocyanate-terminated polyethylene glycol

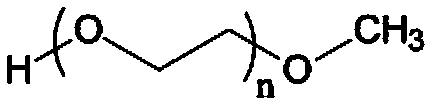

[0026]Methoxy Polyethylene Glycol (Methoxy Polyethylene Glycol, referred to as mPEG) and diisocyanate under the catalysis of dibutyltin dilaurate (abbreviated as DBTDL) undergo nucleophilic addition reaction to prepare isocyanate-terminated polyethylene glycol (the present invention is referred to as mPEG-t-NCO), the chemical formula of the methoxypolyethylene glycol is:

[0027]

[0028] In this formula, n=any integer between 7~120.

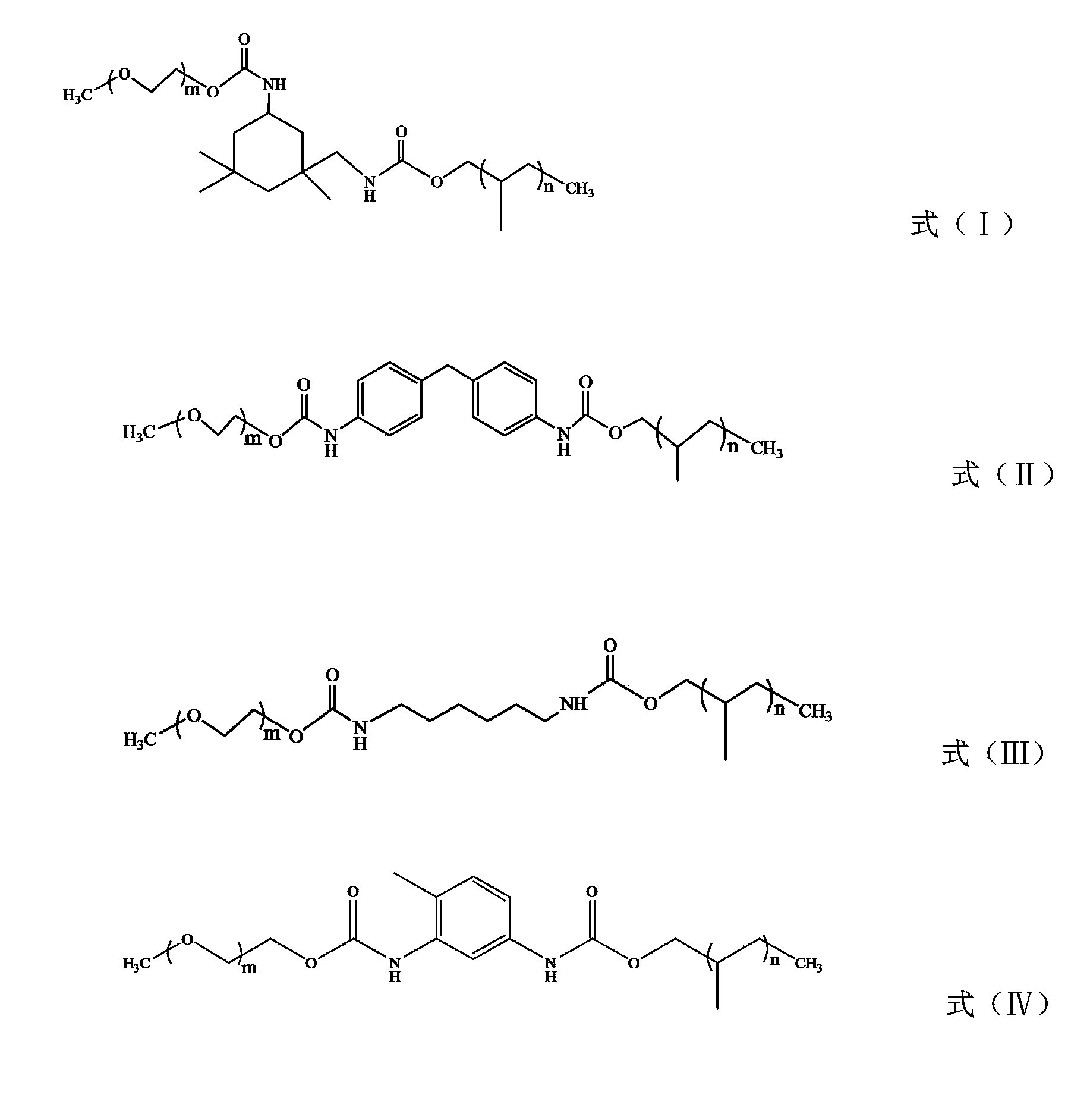

[0029] Used diisocyanate chemical formula is shown in formula (I') or formula (II') or formula (III') or formula (IV'):

[0030]

[0031] The chemical formula of dibutyltin dilaurate used is:

[0032]

[0033] In a Schlenk bottle equipped with a reflux condenser, which was strictly dried and evacuated three times with nitrogen, methoxypolyethylene glycol, diisocyanate, catalyst dibutyltin dilaurate, and solvents (chloroform, tetrachloroethane, etc.) were successively...

Embodiment 1

[0042] 3.5 g (0.01mol) mPEG (M n = 350), 2.5 g (0.1 mol) MDI, 0.06 g dibutyltin dilaurate (1wt.%) and 200 mL chloroform, heated to 25 °C for 8 h, the product was precipitated in a large amount of ether, dissolved in chloroform / ether / After cyclic precipitation three times, vacuum drying was carried out at 40° C. to a constant weight, and 5.5 g of white powder of the intermediate product mPEG-t-NCO was prepared.

Embodiment 2

[0044] Other experimental conditions are with embodiment 1, add 10 g (0.1 mol) (M n = 1000), 12.5g (0.5 mol) MDI, 0.225g dibutyltin dilaurate, and 8.3g white powder of intermediate product mPEG-t-NCO was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com