Method for producing synthetic oil products and chemical products

A technology for chemicals and oils, applied in the field of chemical synthesis, can solve environmental problems and other problems, and achieve the effects of wide application range, low impurity content, and low heavy metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

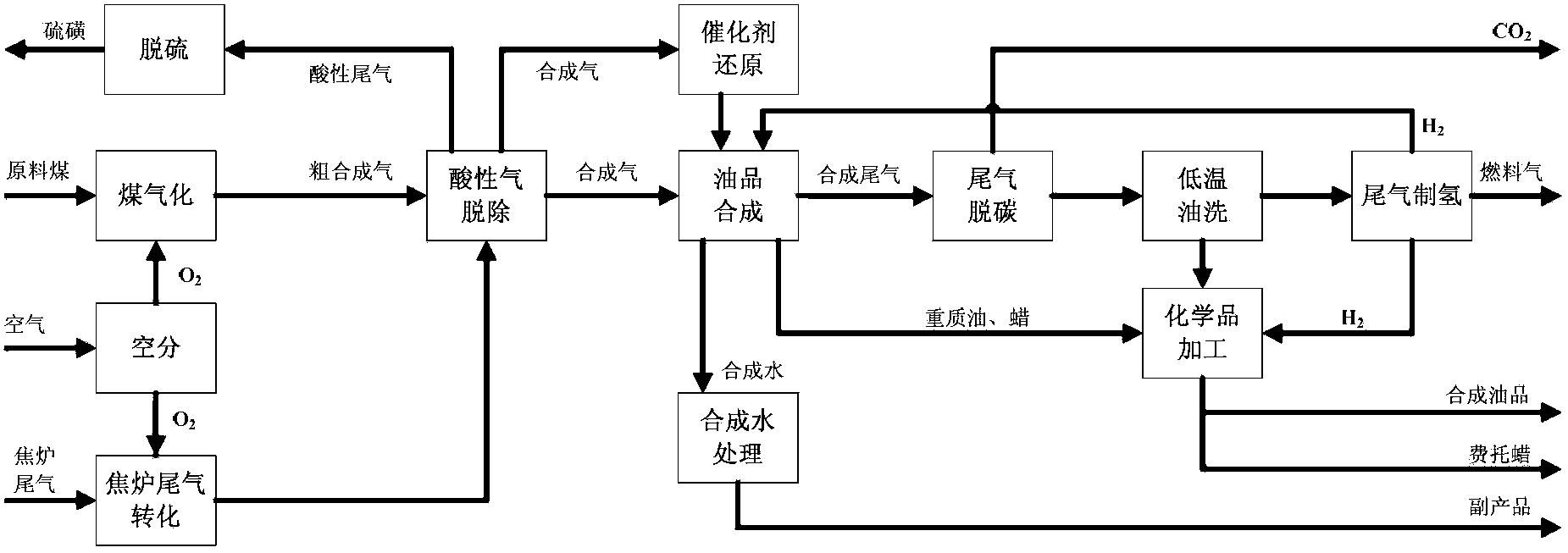

[0033] The schematic diagram of the process of synthesizing oil products and chemicals in this embodiment is as follows figure 1 shown.

[0034] The composition of the coke oven tail gas raw material gas used in the present invention is as follows:

[0035] Table 1 Average composition of purified coke oven tail gas (vol%)

[0036] name

H 2

CH 4

N 2

CO

CO 2

C n h m

O 2

components

58.0

25.0

4.0

7.0

2.7

2.55

0.6

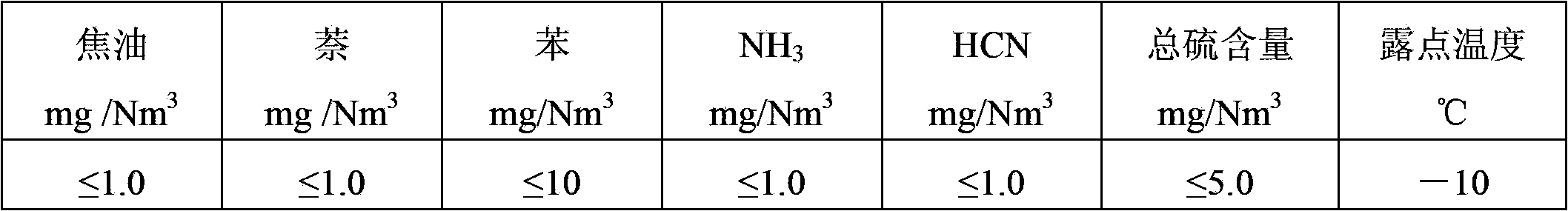

[0037] Table 2 Purified coke oven tail gas impurity content

[0038]

[0039] Among them: low calorific value: 16891.38kJ / Nm 3 (4041kcal / Nm 3 ); Temperature: 40°C; Pressure: 2.8MPa(G).

[0040] (1) The coke oven tail gas from the gas tank is compressed to about 4.1MPa(G), heated to 250°C by medium-pressure steam in the preheater, mixed with medium-pressure superheated steam, and then sent to the reformer burner; Oxygen of about 4.5MPa(G) from outside the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap