Toner for magnetic single-component development

A single-component, toner technology, applied in the direction of developer, electric recording process applying charge pattern, equipment applying electric recording process of charge pattern, etc., can solve the problem of easy deterioration of image quality, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

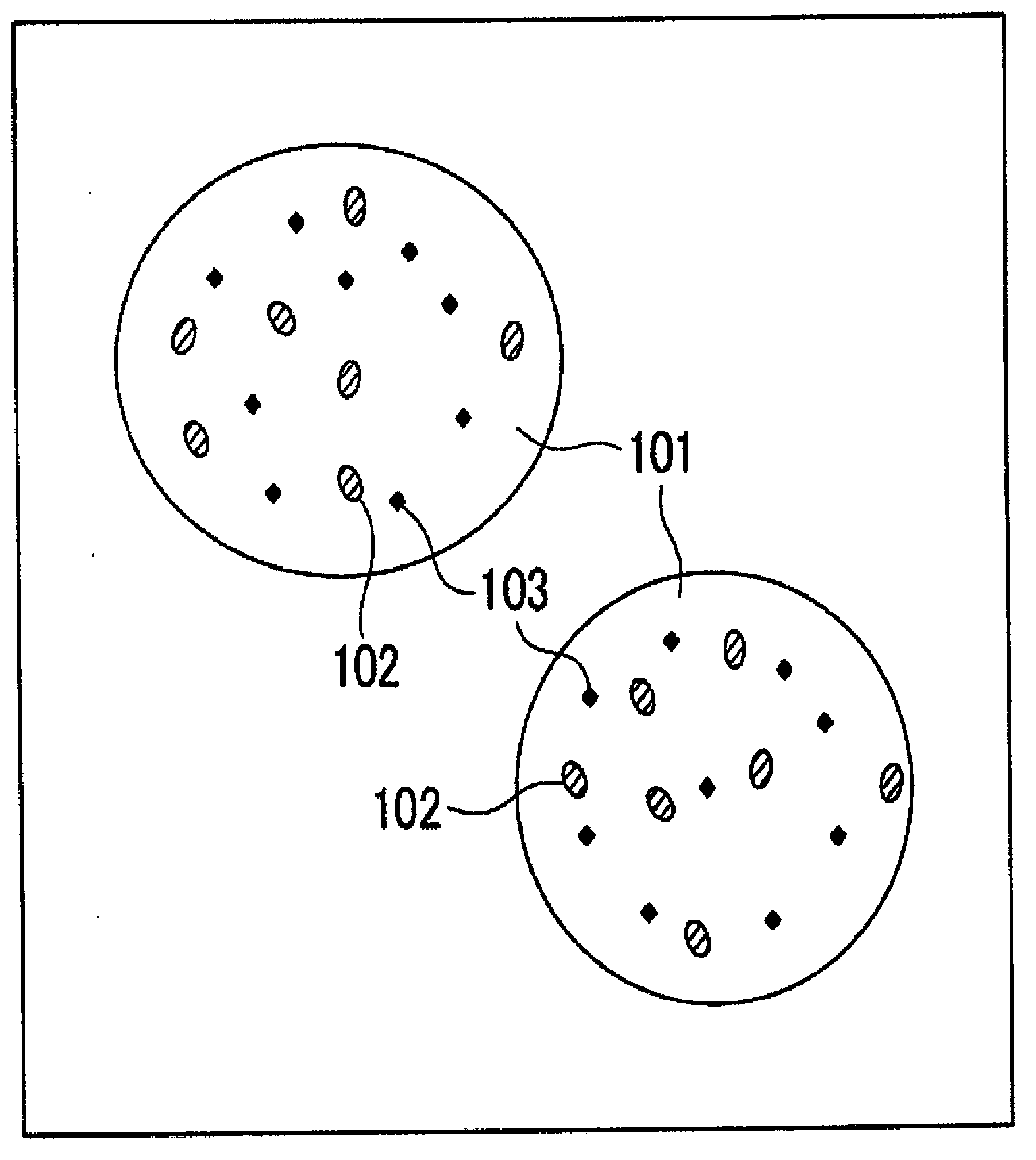

Image

Examples

manufacture example 1

[0076] (production of polyester resin)

[0077] 1,960 g of propylene oxide adducts of bisphenol A, 780 g of ethylene oxide adducts of bisphenol A, 257 g of dodecenyl succinic anhydride, 770 g of terephthalic acid, and dibutyltin oxide were placed in a reaction vessel 4g. The inside of the reaction container was heated up to 235° C. under a nitrogen atmosphere, and the reaction was carried out at this temperature for 8 hours. Thereafter, the inside of the reaction container was decompressed to 8.3 kPa, and the reaction was carried out at this temperature for 1 hour. Next, after cooling the reaction product to 180 degreeC, trimellitic anhydride was added in reaction container, and the acid value of polyester resin was adjusted to about 10 mgKOH / g. Thereafter, the contents of the reaction vessel were heated up to 210° C. at a rate of 10° C. / hour, and a polyester resin was obtained by reacting at this temperature.

manufacture example 2

[0079] (Manufacture of charge control resin)

[0080] A 3-L flask equipped with a stirrer, a capacitor, a thermometer, and a nitrogen introduction tube was used as a reaction vessel. 1000 g of pure water and 4 g of sodium dodecyl sulfate (SDS) were put into the reaction container as an emulsifier, and nitrogen substitution was performed for 30 minutes. Next, in the reaction container, 2 g of potassium persulfate (KPS) was added, stirred and dissolved. Nitrogen gas was introduced into the reaction container to make the inside of the reaction container a nitrogen atmosphere, and then the temperature of the contents of the reaction container was raised to 80°C. Thereafter, while maintaining the state of 80°C, a mixed monomer composed of 300 g of styrene and 60 g of 2-ethylhexyl acrylate (2-EHA), and 2-acrylamide-2-methylpropanesulfonic acid An aqueous solution of (AAPS) 40 g dissolved in 600 g of pure water was dropped into the flask over 2 hours. Thereafter, polymerization wa...

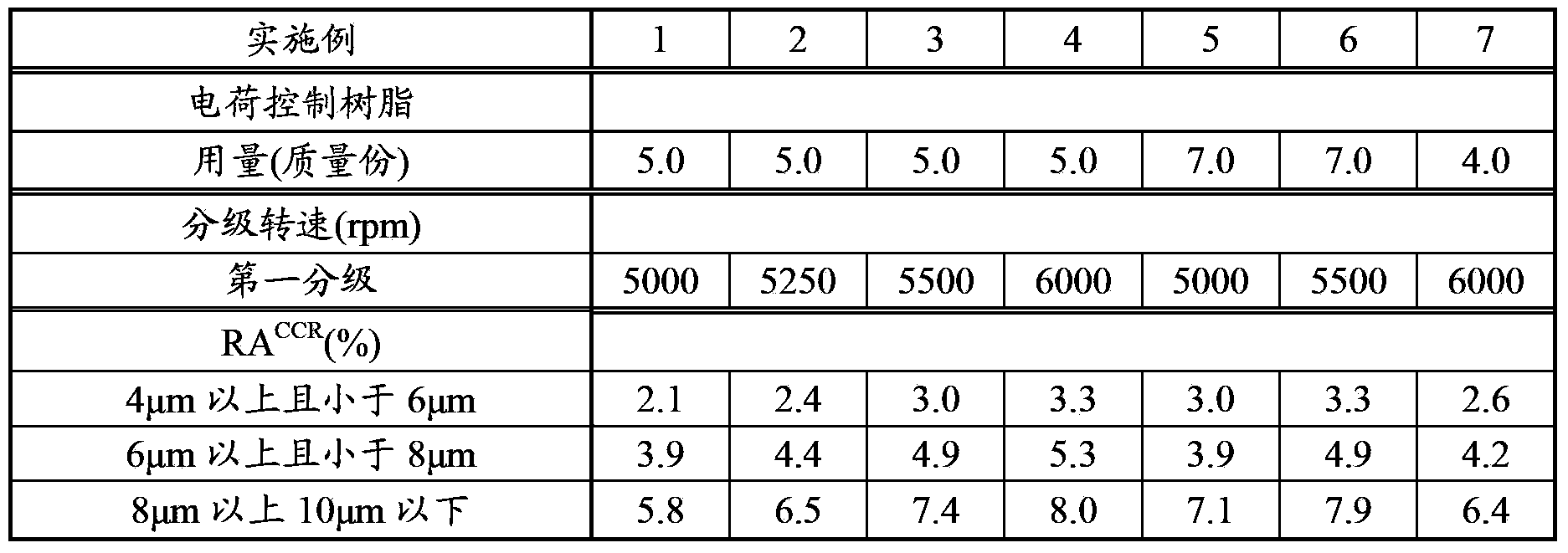

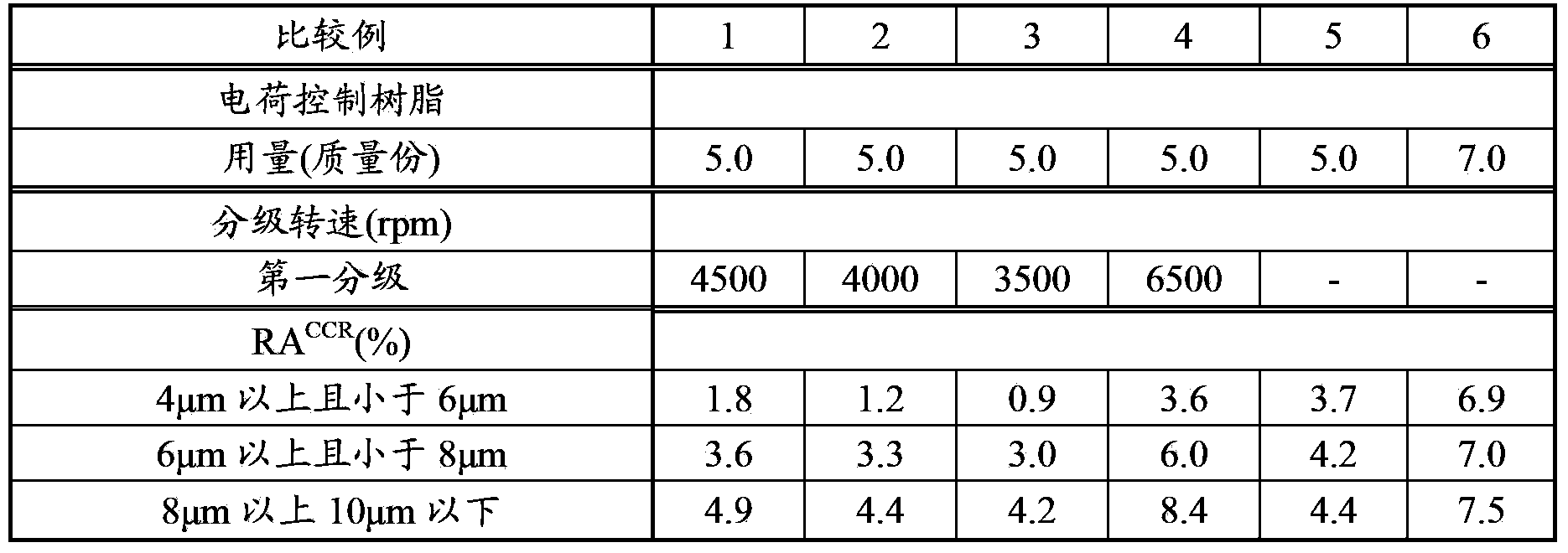

Embodiment 1~7 and comparative example 1~6

[0082] (Preparation of Toner Masterbatch)

[0083] Using a Henschel mixer, 45 parts by mass of a binder resin (polyester resin obtained in Production Example 1), 5 parts by mass of a release agent (carnauba wax (manufactured by Kato Yoko Co., Ltd.)), and a charge control resin (manufactured in Example 1) were mixed. 5 parts by mass of the styrene-acrylic acid copolymer obtained in 2) and 45 parts by mass of magnetic powder (magnetite, TN-15 (manufactured by Mitsui Metal Mining Co., Ltd.)). The obtained mixture was melt-kneaded using a twin-screw extruder, and then cooled. The obtained melt-kneaded product was coarsely pulverized using a hammer mill (Feather Mill FM-1 type (manufactured by Hosokawa Micron Co., Ltd.)). The obtained coarsely pulverized product was finely pulverized using a mechanical pulverizer. Thereafter, the first classification was performed using a rotor rotating classifier (200TSP (manufactured by Hosokawa Micron Co., Ltd.)) at the rotation speed (rpm) de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com