Self-assembly preparation of one-dimensional nano-structure

A nanostructure and self-assembly technology, applied in the field of self-assembly preparation of Au or Ag nanoparticles, can solve the problems of restricting one-dimensional nanostructure research, complicated product separation steps, and difficult to repeat the process, which is beneficial to repetition and environmental protection. , easy to repeat and apply, easy to manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

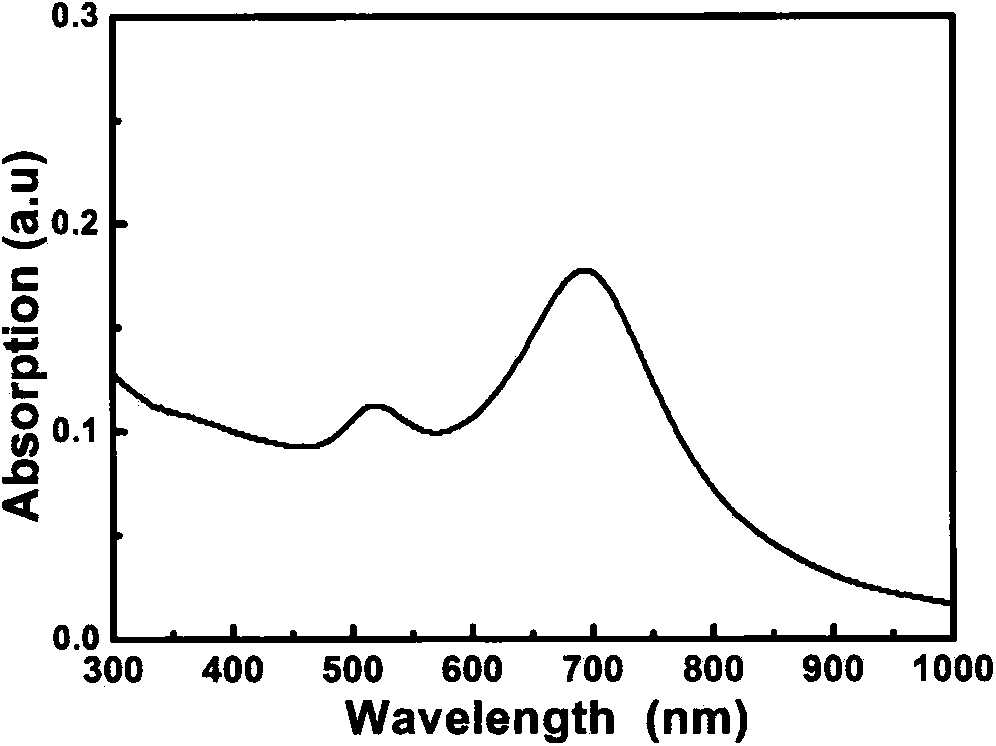

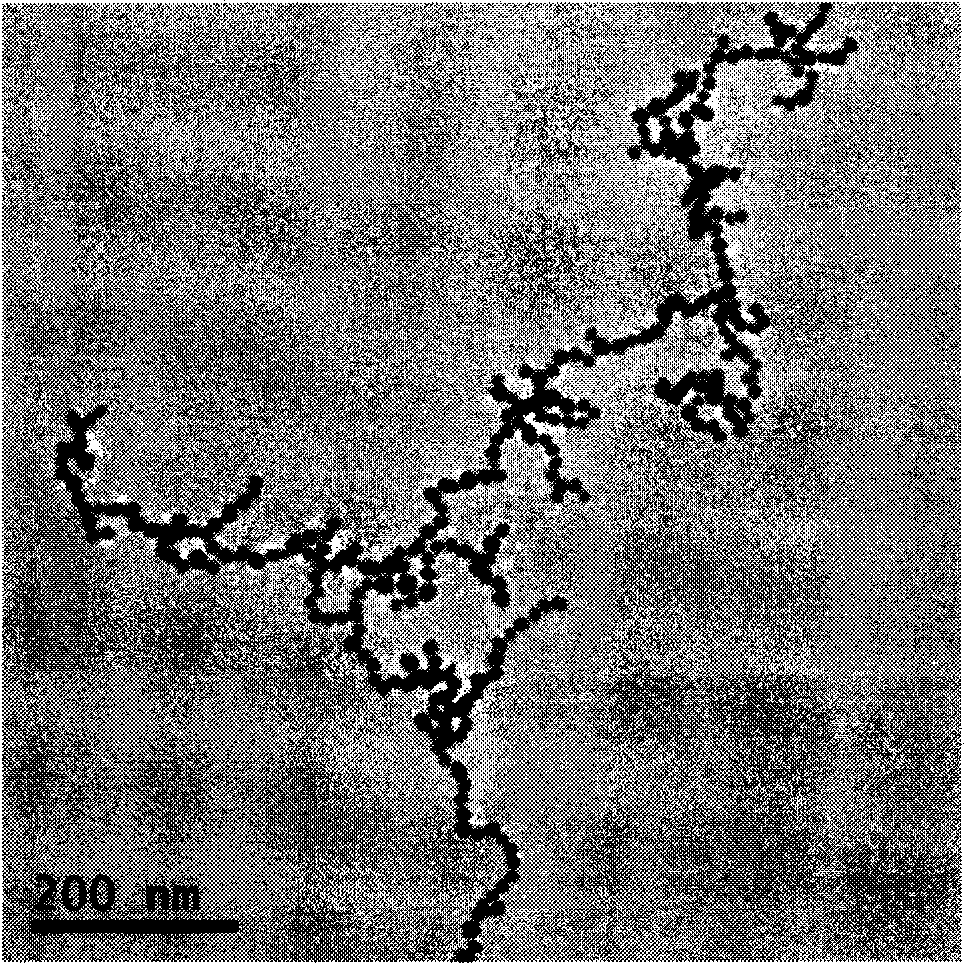

[0027] Take 50mL of deionized water and add it to a three-neck flask, then add about 2mL of HAuCl 4 (concentration of 25mM) solution, stirred, heated to about 100 degrees, refluxed, then added 5mL of sodium citrate solution (concentration of 38.8mM), reacted for about 10min to obtain a colloidal solution of Au. Take about 2mL of gold colloidal solution and centrifuge to obtain a precipitate, disperse it in 5mM NaCl solution, add ethanol, the mixed solution of ethanol / water with a volume ratio of 9:1, let it stand for 60min, then add 0.5mL ammonia water in ethanol solution, Stir to obtain a one-dimensional gold nanostructure ( figure 1 ). UV-vis spectrum ( figure 2 ) proves that the one-dimensional structure has two obvious SPR absorption peaks, and the absorption peak located at about 600nm is the long-axis plasmon coupling peak, which proves the formation of one-dimensional structure, while the transmission electron microscope picture ( image 3 ) fully demonstrates that ...

Embodiment 2

[0029] Take 50mL of deionized water and add it to a three-neck flask, then add about 2mL of HAuCl 4 (concentration of 25mM) solution, stirred, heated to about 100 degrees, refluxed, then about 1.5mL of sodium citrate solution (concentration of 38.8mM) was added and reacted for about 10min to obtain a colloidal solution of Au. Take about 2mL of gold colloidal solution and centrifuge to obtain a precipitate, disperse it in 15mM NaCl solution, add ethanol, the mixed solution of ethanol / water with a volume ratio of 9:1, let it stand for 60min, then add 0.5mL ammonia water in ethanol solution, stir A one-dimensional gold nanostructure was obtained. UV-Vis spectra ( Figure 4 ) proves that the one-dimensional structure has two obvious SPR absorption peaks, and the absorption peak above 700nm is the long-axis plasmon coupling peak, which proves the formation of a one-dimensional structure and fully demonstrates that most of the particles are assembled into a one-dimensional nanostru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com