Radiation-proof emulsion paint and preparation method thereof

A technology of anti-radiation and latex paint, which is applied in the field of anti-radiation latex paint and its preparation, can solve problems affecting the effect of electromagnetic radiation protection, and achieve the effects of improving the effect of anti-radiation, convenient construction, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

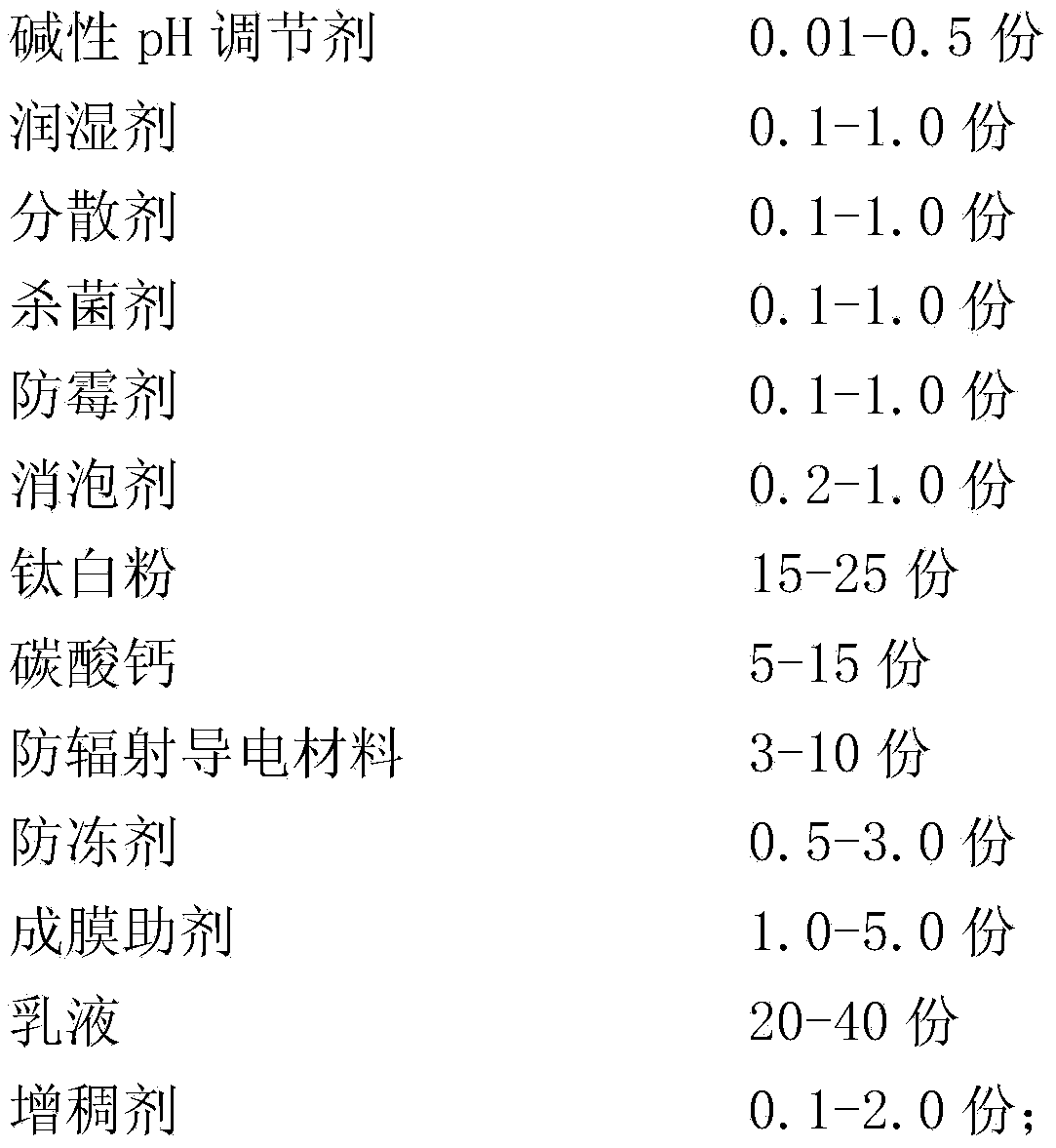

[0044] The preparation method of above-mentioned anti-radiation latex paint, it comprises the following steps carried out in sequence:

[0045] 1) Mix 10-30 parts of water, 0.1-1.0 parts of cellulose, 0.01-0.5 parts of alkaline pH regulator, 0.1-1.0 parts of wetting agent, 0.1-1.0 parts of dispersing agent under stirring at 200-900r / min , 0.1-1.0 parts of bactericide, 0.1-1.0 parts of fungicide and 0.1-0.5 parts of defoamer are added to the container, and stirred for 5-20min;

[0046] 2) Continue to add 15-25 parts of titanium dioxide, 5-15 parts of calcium carbonate and 3-10 parts of anti-radiation conductive materials into the container under stirring at a speed of 1500-3200r / min, and beat for 15-30 minutes;

[0047]3) After stirring at a speed of 500-1000r / min, continue to add 0.5-3.0 parts of antifreeze, 1.0-5.0 parts of film-forming aids, 20-40 parts of emulsion, and 0.1-0.5 parts of defoamer into the container, and stir evenly Finally, use 0.1-2.0 parts of thickener and...

Embodiment 1

[0056] Anti-radiation latex paint, which is made of the following raw materials in weight ratio:

[0057]

[0058]

[0059] The preparation method of above-mentioned anti-radiation latex paint, it comprises the following steps carried out in sequence:

[0060] 1) Mix 25 parts of water, 0.35 part of cellulose, 0.2 part of alkaline pH regulator, 0.15 part of wetting agent, 0.6 part of dispersant, 0.2 part of fungicide, 0.2 part of antifungal agent under stirring at 600r / min Add 0.3 parts of defoamer to the container and stir for 10 minutes;

[0061] 2) Then, at 2000r / min, continue to add 21.6 parts of titanium dioxide, 5 parts of calcium carbonate and 3 parts of radiation-proof conductive materials into the container, and beat for 20 minutes;

[0062] 3) After stirring at a speed of 900r / min, continue to add 1.5 parts of antifreeze, 1.2 parts of film-forming aids, 35 parts of emulsion, and 0.5 parts of defoamer to the container. After stirring evenly, use 0.2 parts of thi...

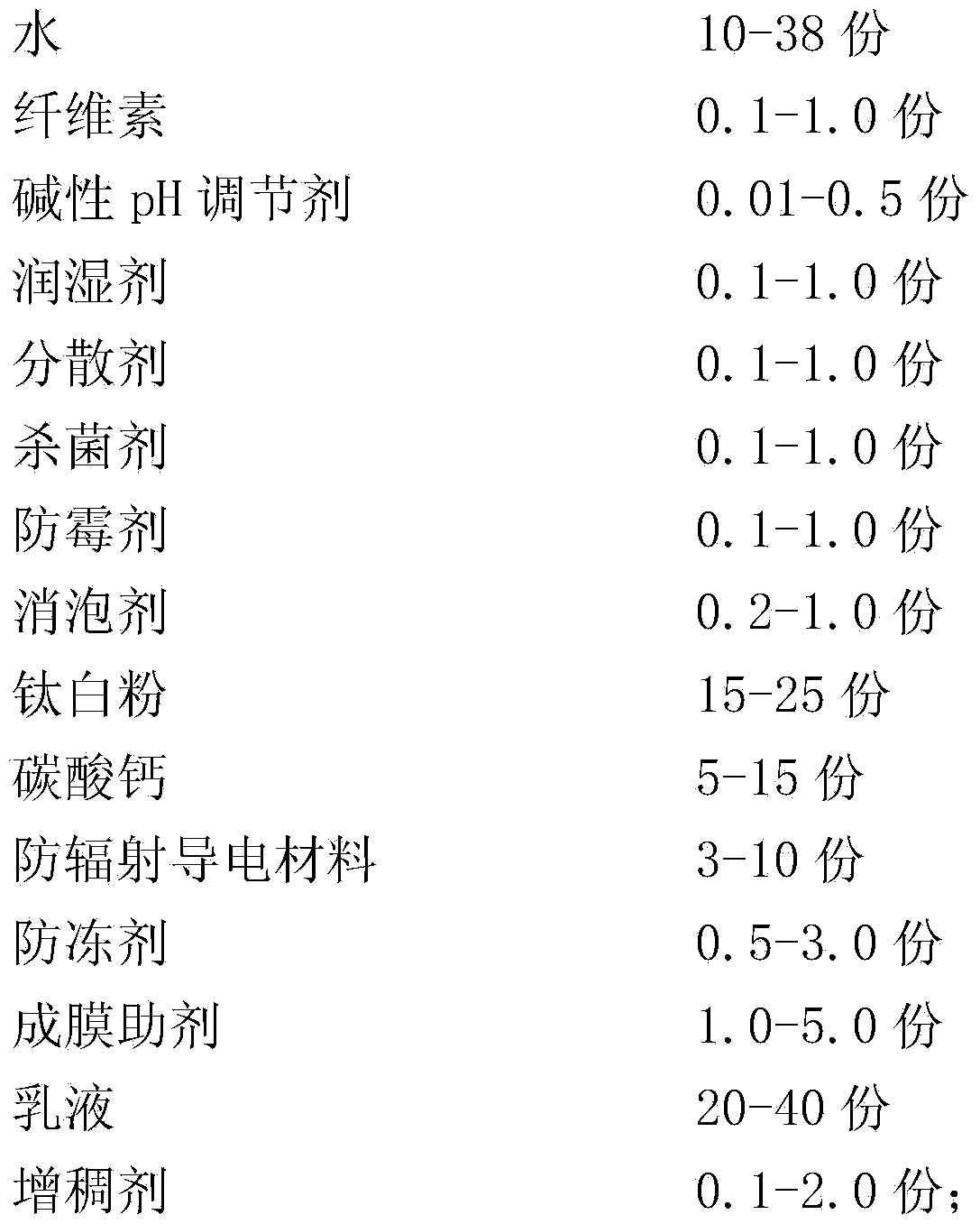

Embodiment 2

[0070] Anti-radiation latex paint, which is made of the following raw materials in weight ratio:

[0071]

[0072]

[0073] The preparation method of above-mentioned anti-radiation latex paint, it comprises the following steps carried out in sequence:

[0074] 1) Mix 18 parts of water, 0.5 part of cellulose, 0.5 part of alkaline pH regulator, 0.1 part of wetting agent, 0.5 part of dispersant, 0.1 part of fungicide, 0.5 part of antifungal agent and Add 0.15 parts of defoamer into the container and stir for 15 minutes;

[0075] 2) Continue to add 15 parts of titanium dioxide, 10 parts of calcium carbonate and 8.8 parts of anti-radiation conductive materials into the container under stirring at a speed of 3200r / min, and beat for 30 minutes;

[0076] 3) After stirring at 1000r / min, continue to add 2.0 parts of antifreeze, 1.0 parts of film-forming aid, 40 parts of emulsion, and 0.35 parts of defoamer to the container. After stirring evenly, use 0.5 parts of thickener and 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com