Preparation method for foamy copper

A technology of foamed copper and copper powder, which is applied in the field of powder metallurgy to prepare metal porous materials, can solve the problems of not being able to prepare spherical holes, air pollution, etc., and achieve the effects of good shape, easy removal, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0030] Embodiment one: the preparation method of the copper foam of this embodiment is:

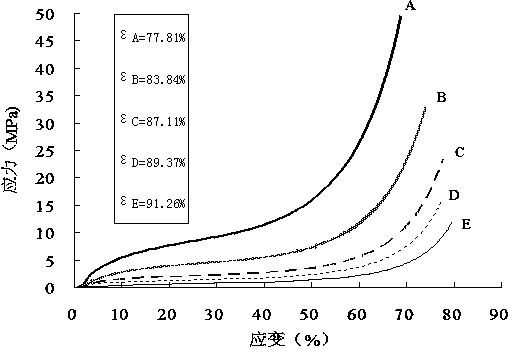

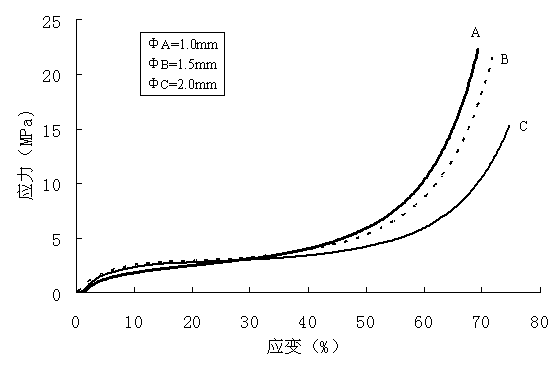

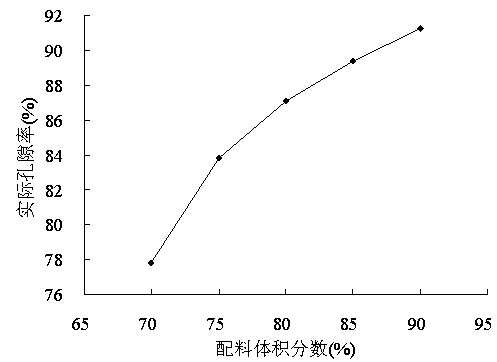

[0031] (1) Copper powder (copper powder is an irregularly shaped copper powder with a particle size of 100-150 μm, with a purity greater than 99.6%) and pore-forming agent anhydrous calcium chloride spherical particles (with a particle size range of 1.5mm) according to a volume ratio of 30 : 70 ingredients, then add water (the addition of water is 5wt% of the total amount of copper powder and pore-forming agent) as a binder for mixing, and then the mixture is pressed into a billet and dried. The pressure of pressing the billet is 400MPa, The holding time is 10 minutes, and the condition of drying the billet is to dry at 120°C for 5 hours;

[0032] (2) Place the dried billet in an argon or nitrogen atmosphere to sinter at a rate of ℃ / min to 900 ℃ for 3 hours, and then cool with the furnace;

[0033] (3) Soak the sintered billet in running water for 60 minutes, remove the moisture by centr...

Embodiment approach 2

[0034] Embodiment two: the preparation method of the copper foam of this embodiment is:

[0035] (1) Copper powder (copper powder is an irregular-shaped copper powder with a particle size of 40-150 μm, with a purity greater than 99.6%) and pore-forming agent anhydrous calcium chloride spherical particles (with a particle size range of 2mm) according to a volume ratio of 15: 85 ingredients, then add water (the amount of water added is 2wt% of the total amount of copper powder and pore-forming agent) as a binder for mixing, and then press the mixture into a billet and dry it. The pressure of pressing the billet is 500MPa. The pressing time is 5min, and the condition of drying the blank is to dry at 150°C for 4h;

[0036] (2) Place the dried billet in an argon or nitrogen atmosphere at a rate of 5°C / min to 1000°C for sintering for 1 hour, then cool with the furnace;

[0037](3) Soak the sintered billet in running water for 30 minutes, remove the moisture by centrifugation, and t...

Embodiment approach 3

[0038] Embodiment three: the preparation method of the copper foam of this embodiment is:

[0039] (1) Copper powder (copper powder is an irregularly shaped copper powder with a particle size of 40-80 μm, with a purity greater than 99.6%) and pore-forming agent anhydrous calcium chloride spherical particles (with a particle size range of 3.3 mm) according to a volume ratio of 10 : 90 ingredients, then add water (the addition of water is 4wt% of the total amount of copper powder and pore-forming agent) as a binder for mixing, then the mixture is pressed into a billet and dried, the pressure of the pressed billet is 450MPa, The holding time is 8 minutes, and the condition of drying the billet is to dry at 130°C for 4.5 hours;

[0040] (2) Place the dried billet in an argon or nitrogen atmosphere at a rate of 10°C / min to 800°C for sintering for 1 hour, then cool with the furnace;

[0041] (3) Soak the sintered billet in running water for 40 minutes, remove the moisture by centri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com