Roof panel

A technology of roof panels and load-bearing surfaces, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve the problems of large occupied area, complex structure, and time-consuming production site, and achieve simplified construction procedures and truss structures. Simple, quality-controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

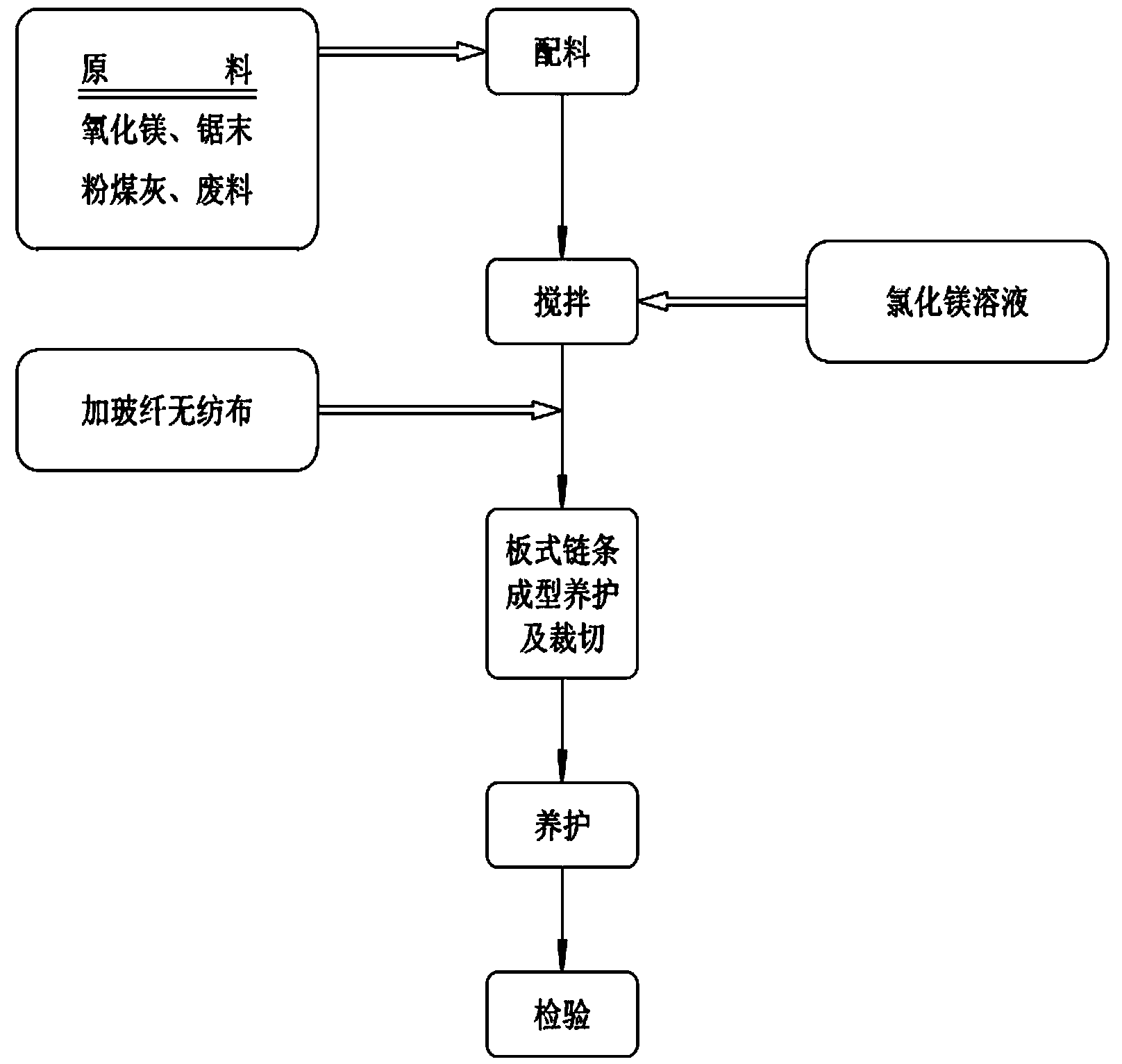

Method used

Image

Examples

Embodiment 1

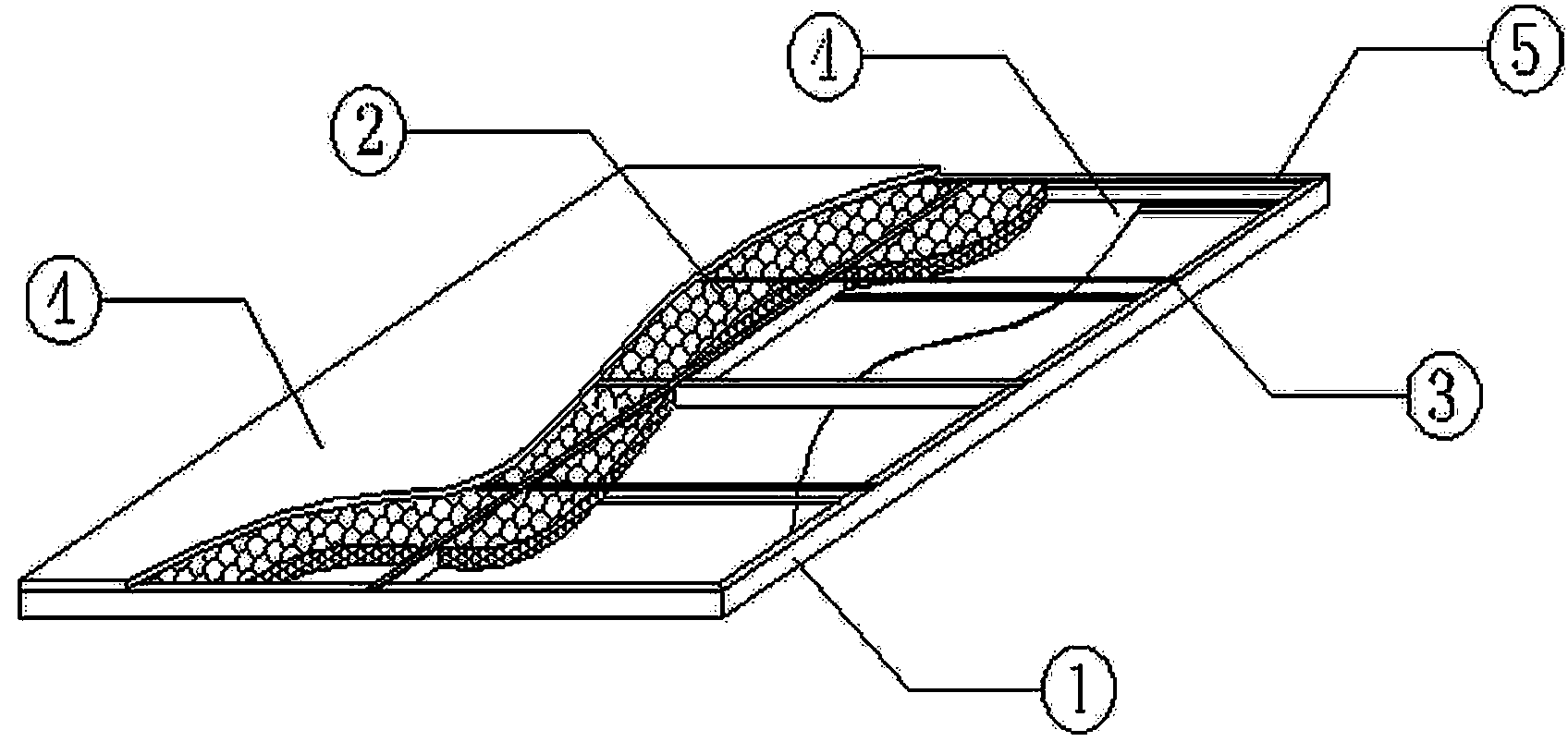

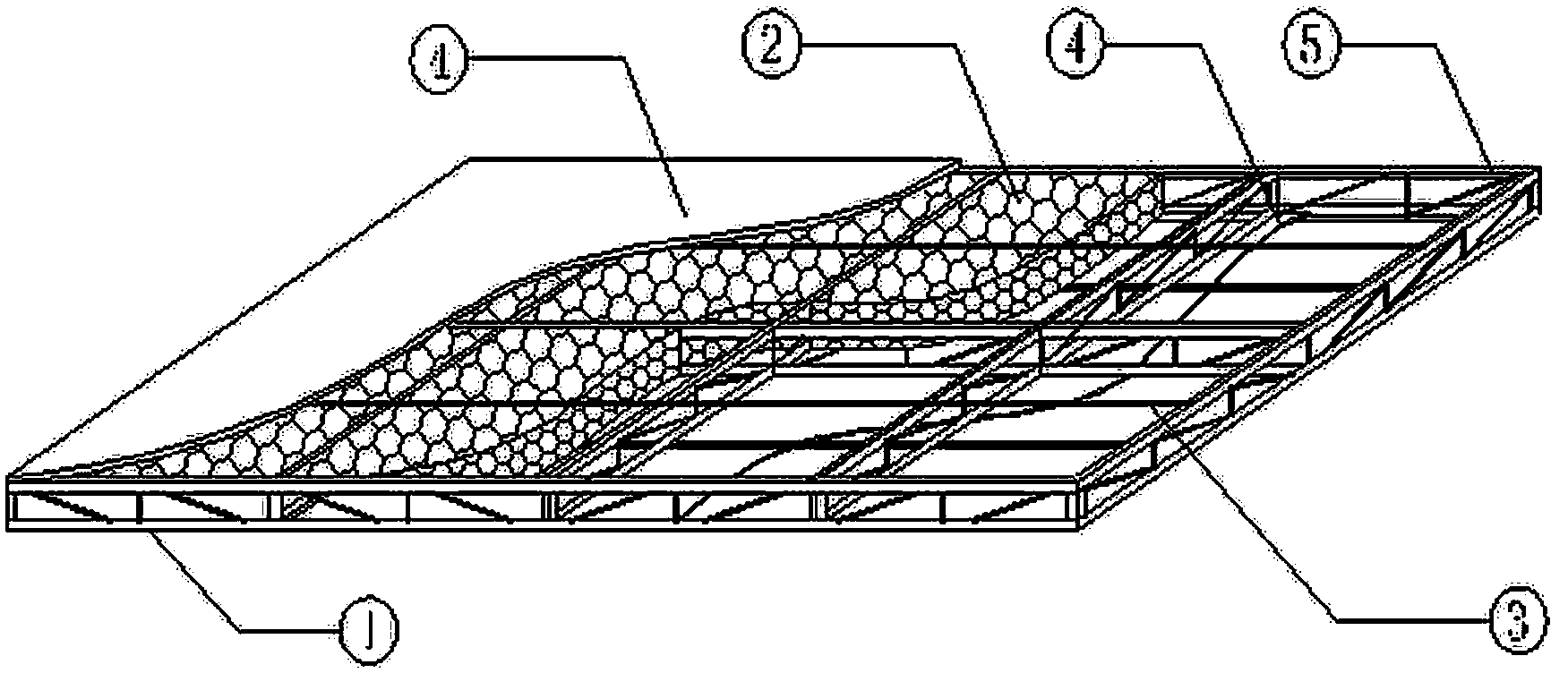

[0085] A roof panel including a truss structure (C-shaped steel frame structure) , bearing surface , thermal insulation filling layer , where the thermal insulation filling layer is the middle layer inside the roof panel truss structure (C-shaped steel frame structure), the upper and lower sides of the truss structure (C-shaped steel frame structure) are connected to the upper and lower load-bearing surface layers, and the three are connected by bonding or bolts; the load-bearing surface The layer includes upper and lower layers of glass fiber, magnesium-containing composite material layer and filler. It is characterized in that the upper and lower layers of the load-bearing surface layer are made of glass fiber, and the lower layer of glass fiber on the upper load-bearing surface layer is a layer of reinforcing material; magnesium-containing composite material The material and filler are in the middle layer, and the glass fiber and reinforcing material are combined into a...

Embodiment 2

[0087] The difference from Example 1 is that the addition ratio of the filler fly ash used is 6%, and the addition ratio of sawdust is 30%. The flexural strength of magnesium oxychloride cement is 18MPa. Also add 4% finished product powder crushing material, the mesh number of powder body crushing material is 400 mesh. In addition, the reaction temperature of the magnesium-containing composite material is 80°C. When mixing magnesium oxychloride cement and filler, use a high-speed mixer to fully mix within 4-5 minutes, and the speed of the mixer reaches 70 rpm. The glass fiber used is medium-alkali glass fiber mesh cloth, the curing temperature of the load-bearing surface layer is 65 ℃, and the curing humidity is 60%. The insulation filling layer used for the roof panel is rock wool or mineral wool board.

Embodiment 3

[0089] The difference from Example 1 is that the addition ratio of the filler fly ash used is 5%. The flexural strength of magnesium oxychloride cement is 14MPa. Also added 4% finished product powder crushed material. In addition, the reaction temperature of the magnesium-containing composite material is 45°C. When mixing magnesium oxychloride cement and filler, use a high-speed mixer to fully mix within 4-5 minutes, and the speed of the mixer reaches 60 rpm. Before stirring, the powdered raw materials should be pre-stirred, and then liquid magnesium chloride should be added and stirred for at least 3-4 minutes. The glass fiber used is medium-alkali glass fiber mesh cloth, the curing temperature of the load-bearing surface layer is 25°C, and the curing humidity is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com