Rapid preparation method of rod-like nano-hydroxyapatite

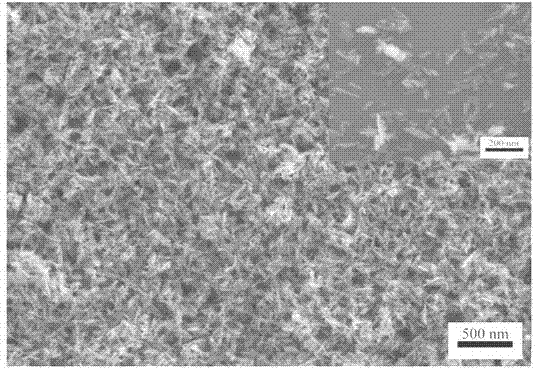

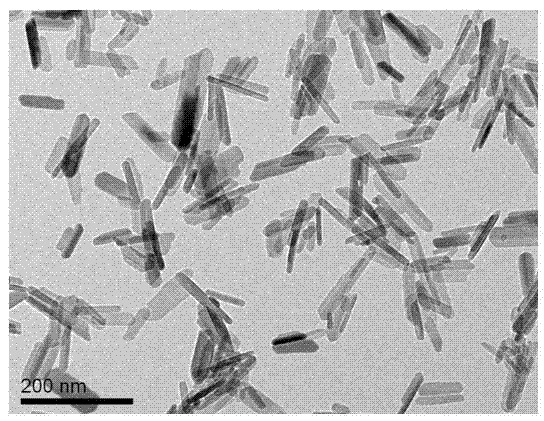

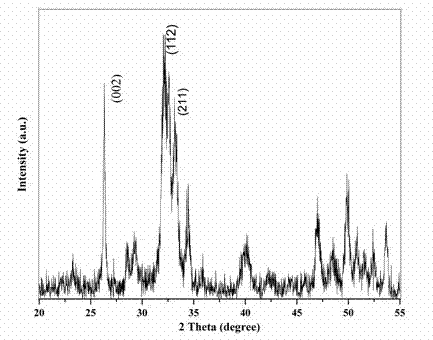

A nano-hydroxyapatite, rod-shaped technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of increasing the toxicity of hydroxyapatite, cumbersome methods, etc., achieve uniform and controllable morphology, and the preparation method Simple, mild and controllable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take 3 ml of 0.09 M DTAB solution, add DTAB solution into 177ml of deionized water, stir at 300 rpm for 30 minutes until DTAB is evenly dispersed in the aqueous solution, and the final concentration of DTAB is 1.5×10 -3 mol / L.

[0026] 2) At a temperature of 30 or 40°C, add 60ml of 0.03M Na 2 HPO 4 The aqueous solution was added to the above solution, stirred at a stirring rate of 200 rpm for 30 minutes, and the pH value of the mixed solution was adjusted to 11 with 1M NaOH.

[0027] 3) Add 60ml, 0.05M CaCl 2 The aqueous solution is added dropwise to the above solution, so that the Ca / P molar ratio of the final reaction system is 1.67, and the dropping rate is 20 or 50 drops / min. During the dropping process, NaOH solution is added dropwise to maintain the pH value of the reaction system at 10 , maintain the temperature at 60° C., and maintain the stirring rate at 300 rpm.

[0028] 4) After the dropwise addition, continue to stir for 12 hours, and then react for ...

Embodiment 2

[0031] 1) Take 5ml of 0.09M DTAB solution, add it to 175ml of deionized water, stir at a stirring rate of 500 rpm for 30 minutes until DTAB is evenly dispersed in the aqueous solution, and the final concentration of DTAB is 2.5×10 -3 mol / L.

[0032] 2) At a temperature of 50 or 70°C, add 100ml of 0.03M Na 2 HPO 4 Aqueous solution was added to the above solution, stirred at a stirring rate of 400 rpm for 30 minutes, and the pH value of the mixed solution was adjusted to 11 with 1M NaOH.

[0033] 3) Add 100ml, 0.05M calcium nitrate aqueous solution dropwise to the above solution, so that the Ca / P molar ratio of the final reaction system is 1.67, and the dropping rate is 30 drops / min. During the dropping process, add NaOH solution dropwise The pH of the reaction system was maintained at 12, the temperature was maintained at 70° C., and the stirring rate was maintained at 400 rpm.

[0034] 4) After the dropwise addition, continue to stir for 8 hours, and then react for 2 hours ...

Embodiment 3

[0037] 1) Take the prepared rod-shaped nano-hydroxyapatite powder, sterilize it under ultraviolet light for 2 hours, and add an appropriate amount of cell culture medium under sterile conditions to ultrasonically resuspend to make the concentration 1mg / mL;

[0038] 2) Spread QSG-7701 cells (normal human liver cells) in a 96-well plate at a concentration of 10,000 cells per well. When the cells enter the exponential growth phase, add the above-mentioned HAp particles, and add them to the HAp wells The final concentrations are 0.005, 0.01, 0.025, 0.05, 0.1 (mg / mL).

[0039] 3) After 48 hours, add 20 microliters of MTT (5 mg / mL) to each well, and after adding MTT for 4 hours, remove the supernatant completely, add 150 microliters of DMSO to each well, shake gently for 12 minutes, and test its presence in the microplate reader. The absorbance value at 490nm was determined by origin8.0 Figure 5 .

[0040] 4) Select the HAp concentration under the optimal cell survival rate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com