Method for preparing controllable-morphology-and-size mixed-valence tungsten-based nanoparticles

A technology of nanoparticle and mixed valence state, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve problems such as complex methods and large product sizes, and achieve simple synthesis steps, uniform particles, and The effect of strong near-infrared absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this example, tungsten hexachloride is used as the tungsten source, the concentration is 15 mmol / L, and n-propanol is used as the reducing agent. The specific preparation steps are as follows:

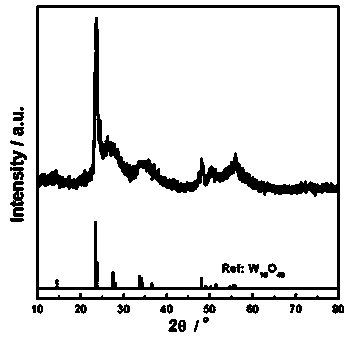

[0030] After adding 50 ml of n-propanol to a 100 ml hydrothermal reaction kettle, add 0.2976 g of tungsten hexachloride powder, and stir and mix at room temperature. After the solution is completely mixed, seal the reaction kettle and place it in an oven at 200°C Crystallized for 22 h. After cooling to room temperature, centrifuge, wash with deionized water and absolute ethanol alternately, and dry in vacuum to obtain mixed valence tungsten-based nanoparticle powder. like figure 2 As shown, the sample prepared in this example is a shuttle-shaped nanoparticle with a length of about 450 nm and a diameter of about 180 nm in the middle.

Embodiment 2

[0032] In this example, tungsten ethanol (Ⅴ) was used as the tungsten source, the concentration was 4.4 mmol / L, and ethanol was used as the reducing agent. The specific preparation steps are as follows:

[0033] After adding 50ml of absolute ethanol to a 100 ml hydrothermal reaction kettle, add 0.09 g of tungsten ethoxide (Ⅴ) dropwise, and stir and mix at room temperature. 22 h. After cooling to room temperature, centrifuge, wash with deionized water and absolute ethanol in sequence, and vacuum dry to obtain mixed valence tungsten-based nanoparticle powder. like image 3 As shown, the sample prepared in this embodiment is a sheet-like nanoparticle with a length and width of about 30 nm.

Embodiment 3

[0035] In this example, tungsten ethoxide (Ⅴ) is used as the tungsten source, the concentration is 10 mmol / L, and ethanol is used as the reducing agent. The specific preparation steps are as follows:

[0036] After adding 50ml of absolute ethanol to a 100ml hydrothermal reaction kettle, add 0.2047 g of tungsten ethoxide (Ⅴ) dropwise, and stir and mix at room temperature. After the solution is completely mixed, seal the reaction kettle and place it in an oven at 200°C for crystallization 22 h. After cooling to room temperature, centrifuge, wash with deionized water and absolute ethanol in sequence, and vacuum dry to obtain mixed valence tungsten-based nanoparticle powder. like Figure 4 As shown, the samples prepared in this embodiment are spherical nanoparticles with a diameter of about 130 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Middle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com