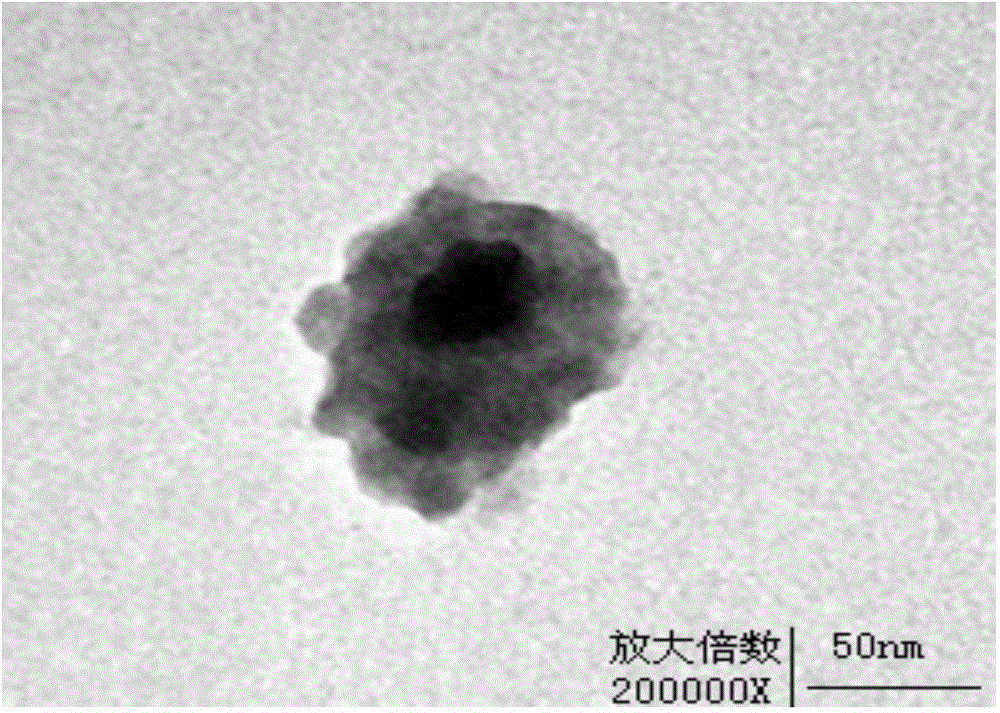

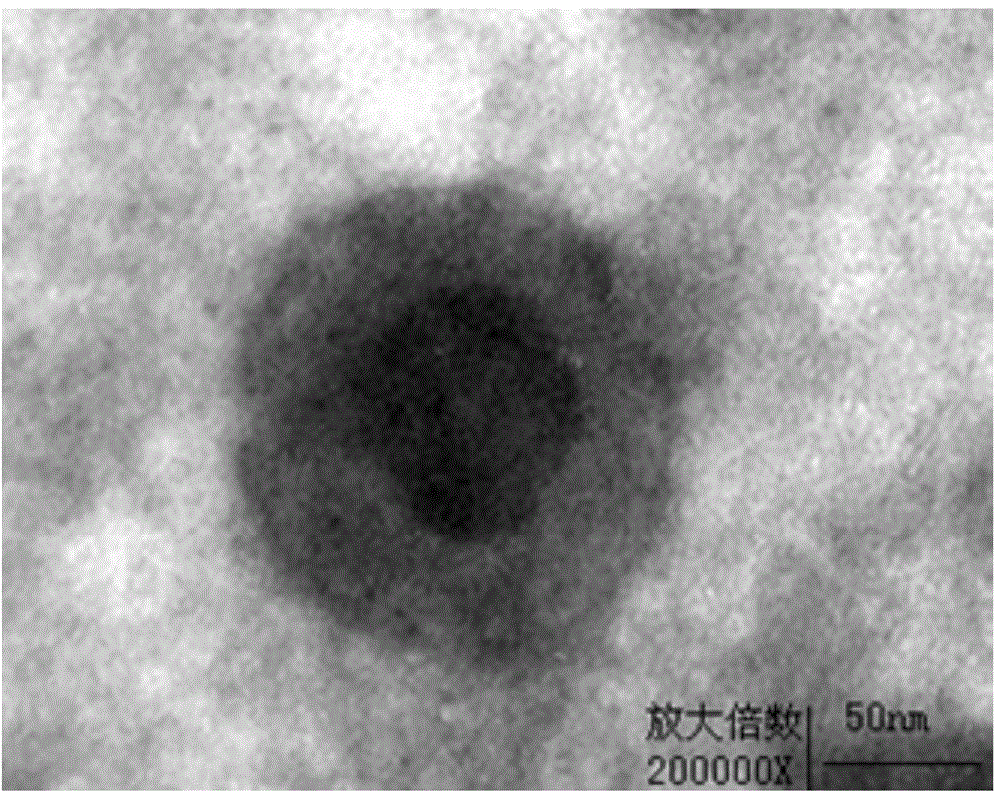

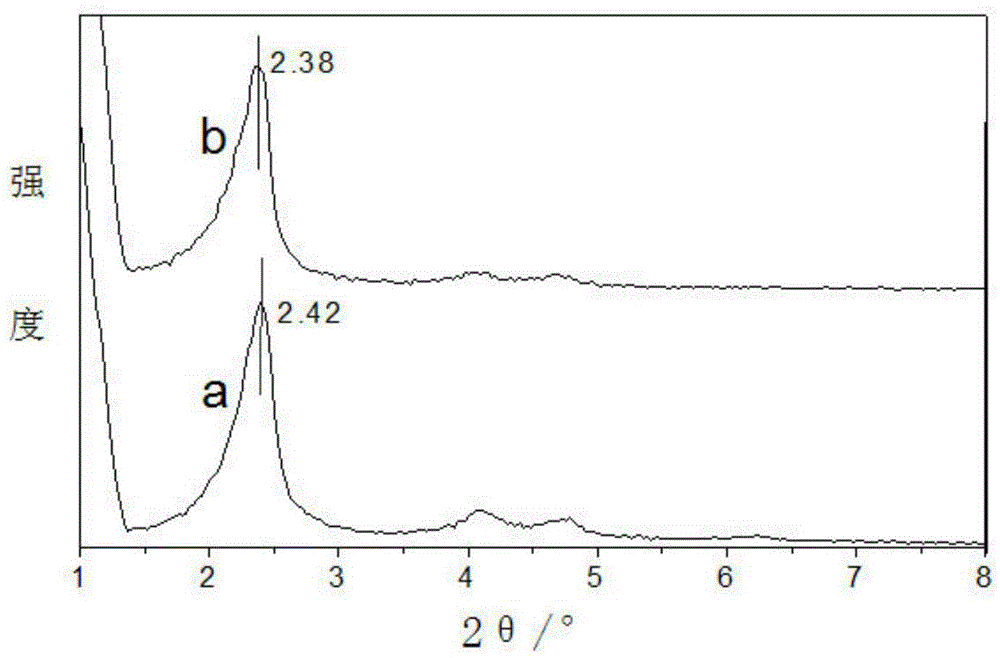

Preparation method of core-shell structured Fe3O4@MCM-41 magnetic nano material

A technology of fe3o4mcm-41 and magnetic nano, which is applied in the preparation of microspheres and microcapsule preparations, can solve the problems of uneven core-shell structure and small specific surface area of magnetic nanomaterials, and achieve thermodynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific embodiment 1: In this embodiment, the core-shell structure Fe 3 o 4 The preparation method of MCM-41 magnetic nanometer material is implemented according to the following steps:

[0022] 1. Dissolve cetyltrimethylammonium bromide (CTAB) and sodium dodecylbenzenesulfonate (SDBS) in twice-distilled water at a molar ratio of 1.0: (1.5 to 3.0) to obtain anions / cations Surfactant mixed solution, the anionic / cationic surfactant mixed solution is left to stand at 25-35°C for 24-48 hours to obtain a vesicle phase solution;

[0023] 2. Mix FeCl with a molar ratio of 2.0:1.0 3 and FeSO 4 Dissolve in double-distilled water that has been treated with nitrogen and deoxygenation to obtain an iron salt solution, add the vesicle phase solution in step 1 to the iron salt solution, ultrasonicate at 25-35°C for 2-3 hours, and then add ethylenediamine to adjust the concentration of the system When the pH value reaches 9-10, a black suspension is obtained;

[0024] 3. Add cety...

specific Embodiment approach 2

[0026]Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one anion / cation surfactant mixed solution, hexadecyltrimethylammonium bromide (CTAB) and sodium dodecylbenzenesulfonate ( SDBS) the total concentration is 0.028 ~ 0.032mol / L. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of Fe ions in the ferrous salt solution in the step is 0.25-0.32 mol / L. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com