Lignin-based foam concrete foaming agent, and preparation method and application thereof

A foamed concrete and lignin-based technology, applied in the field of concrete foaming agent, can solve the problems of incomplete foaming agent performance, poor foaming ability, poor stability, etc. High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

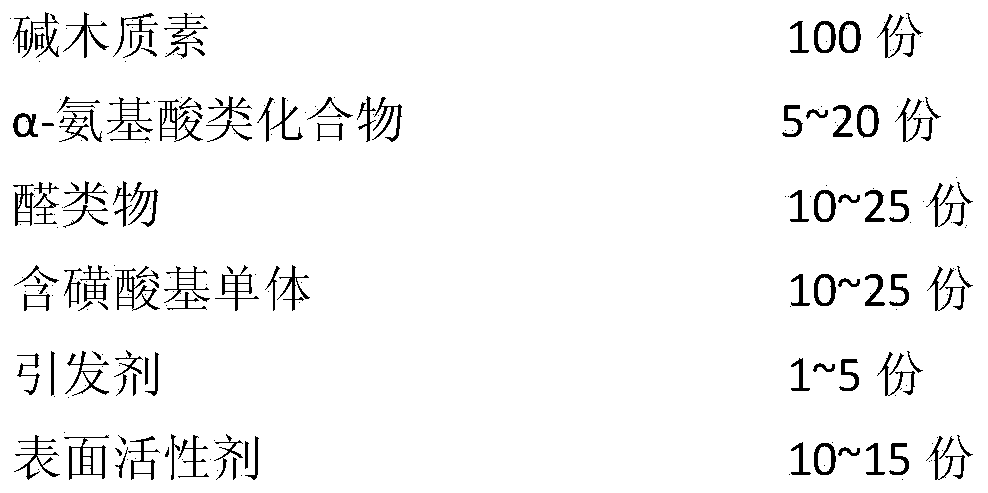

Method used

Image

Examples

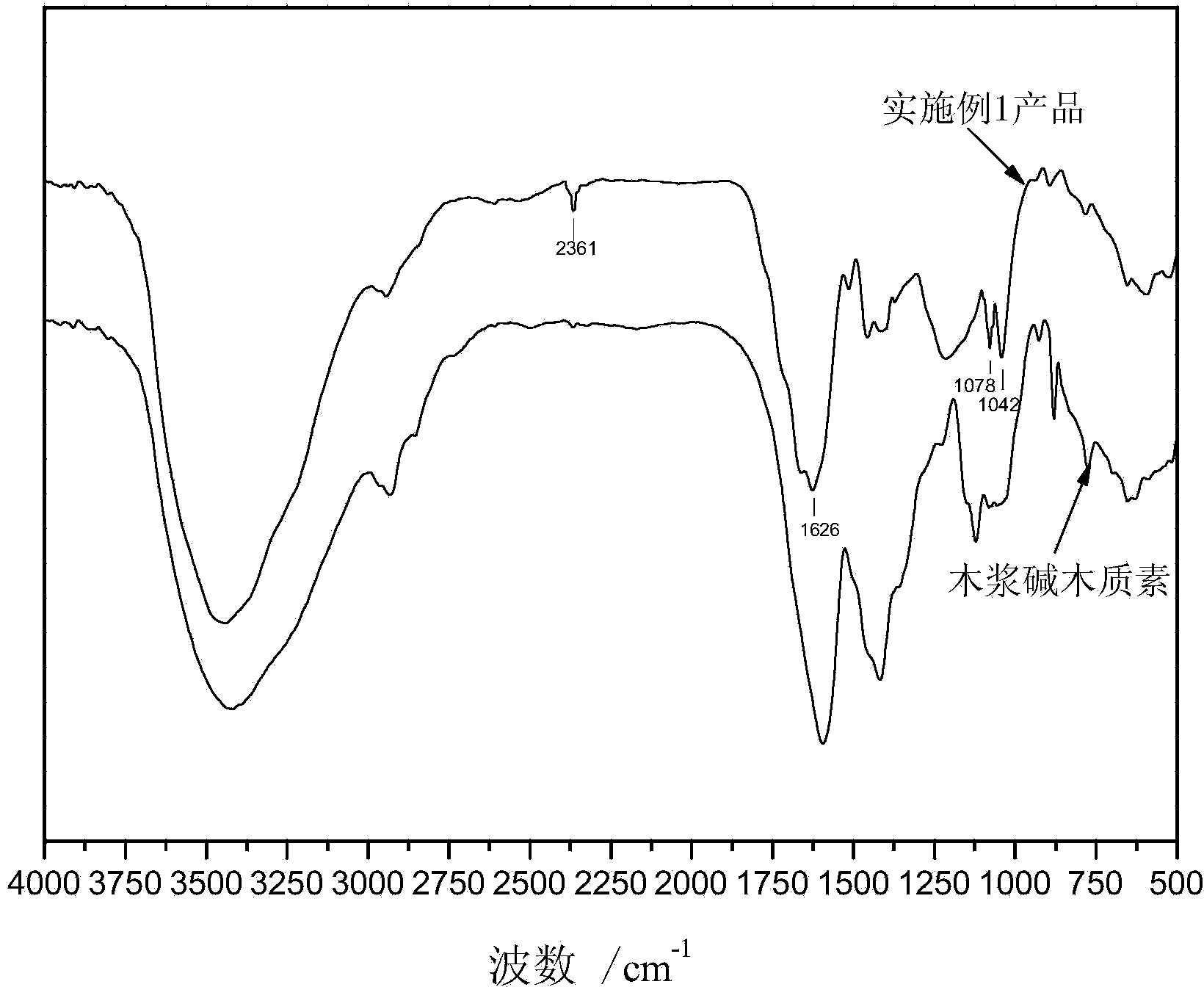

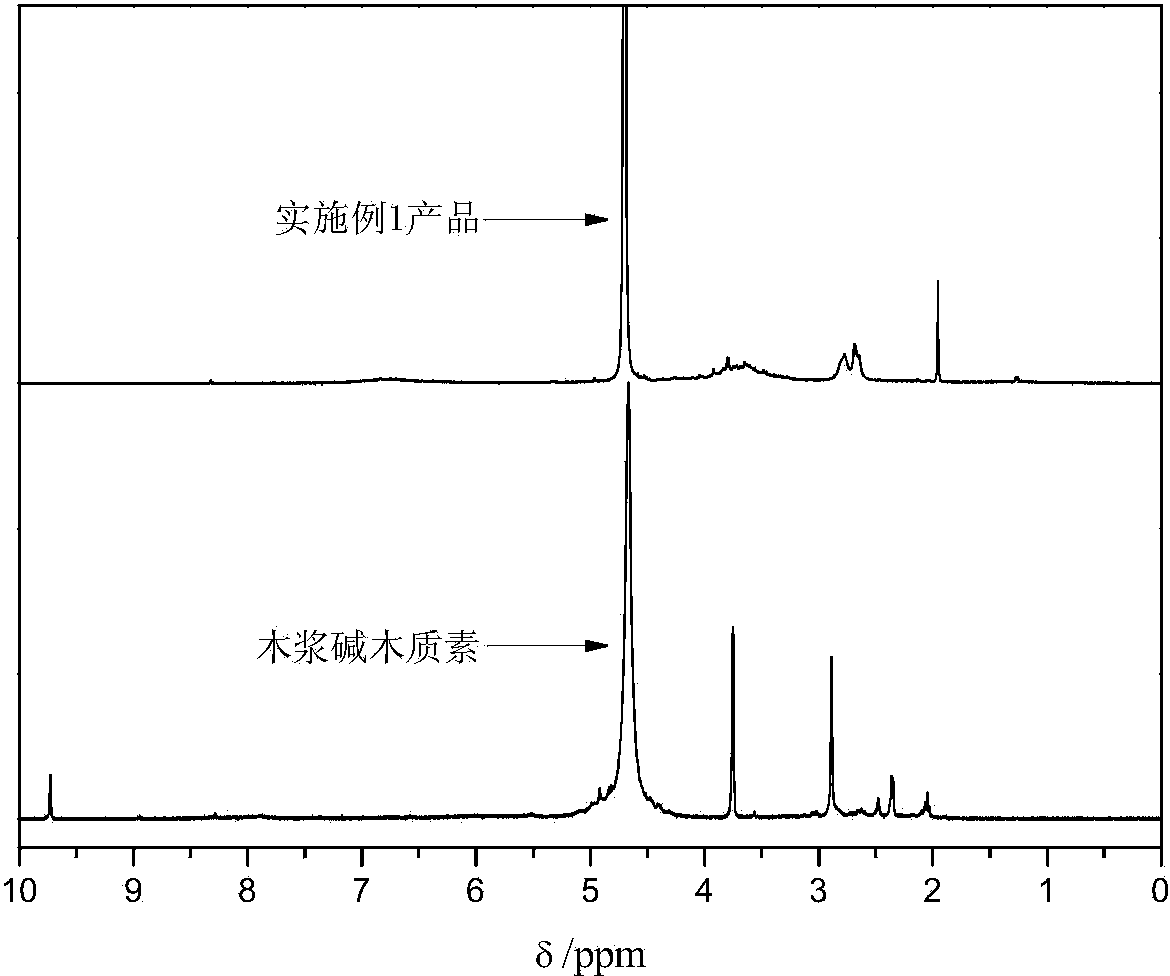

Embodiment 1

[0040] Add 100g of wood pulp alkali lignin solid powder into water, adjust the pH value to 9 with NaOH aqueous solution with a mass fraction of 30% under stirring, and dissolve it into a solution with a mass concentration of 30%; add 20g of sodium glutamate at 60°C , and drop 25g of glyoxal, and react for 3 hours to obtain aminated carboxylated alkali lignin; add 25g sodium styrene sulfonate to the solution of aminated carboxylated alkali lignin, heat up to 70°C, and drop 5g of peroxide Dibenzoyl initiator, react for 3 hours; then add 10g sodium lauryl sulfate and 5g carboxymethyl cellulose to the product, stir evenly, and obtain a liquid lignin-based concrete foaming agent after cooling.

Embodiment 2

[0042] Add 100g of bamboo alkali lignin solid powder into water, adjust the pH value to 11 with KOH aqueous solution with a mass fraction of 30% under stirring, and dissolve it into a solution with a mass concentration of 50%; add 5g of sodium glycinate at a temperature of 70°C, and drop Add 10g of formaldehyde and react for 1h to obtain aminated carboxylated alkali lignin; add 10g of sodium vinyl sulfonate to the solution of aminated carboxylated alkali lignin, raise the temperature to 90°C, and drop 1g of azobisisobutyronitrile to initiate agent, reacted for 4 hours; then added 15g of fatty alcohol sodium sulfate and 2g of polyvinyl alcohol to the product, stirred evenly, and obtained a liquid lignin-based concrete foaming agent after cooling.

Embodiment 3

[0044] Add 100g of wheatgrass lignin solid powder into water, adjust the pH value to 10 with NaOH / KOH mixed aqueous solution with a mass fraction of 30% under stirring, and dissolve it into a solution with a mass concentration of 40%; add 10g of alanine at a temperature of 65°C Sodium acid, and drop 20g of acetaldehyde, react for 2h, to obtain aminated carboxylated alkali lignin; Add 20g of sodium methacryl sulfonate to the solution of aminated carboxylated alkali lignin, heat up to 80 ° C, and drop 3g dibenzoyl peroxide initiator, react for 3h; then add 12g sodium lauryl polyoxyethylene ether sulfate and 4g hydroxyethyl methylcellulose to the product, stir evenly, and obtain liquid lignin-based concrete foam after cooling foaming agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com