Method for quickly and continuously preparing high-molecular-weight polyacrylamide

A technology of polyacrylamide and polyacrylamide copolymer, which is applied in the field of rapid and continuous preparation of water-soluble polymers and rapid and continuous reaction of polyacrylamide, which can solve the problems of difficult heat transfer of PAM colloid, prolonged reaction time and complicated production process and other problems, to achieve the effect of improving labor productivity, simple equipment, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

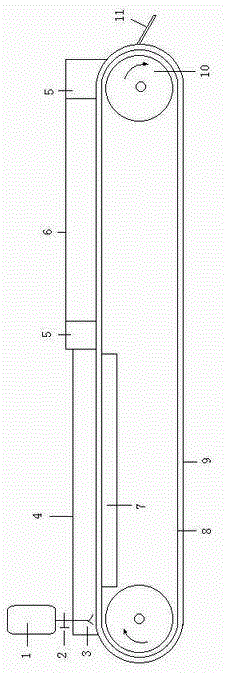

Image

Examples

Embodiment 1

[0028] Add 2000.00 g of 50% AM solution, 40.00 g of urea, 0.30 g of disodium edetate, 0.60 g of isopropanol, and 1930.00 g of deionized water into the batching tank. After deoxygenating with nitrogen for 30 minutes, add 20.00 g 1% ammonium persulfate solution is added to the batching tank, and nitrogen is continued for 10 minutes. The mixed solution and 10.00 g of 1% sodium bisulfite solution are distributed at a certain flow rate to a continuous nitrogen-filled device that rotates at a certain speed Above, react for 50 min under normal temperature and microwave conditions, and finally obtain a colorless transparent colloidal PAM after granulation, drying and crushing to obtain a white powder. After drying, the molecular weight of the powder is 10.435 million, the dissolution time is 150 minutes, and the residual monomer content is 0.04%.

Embodiment 2

[0030] Add 50% AM solution 2000.00 g, 40.00 g urea, 0.30 g disodium edetate, 0.60 g isopropanol, 0.20 g triethylamine and 1930.00 g deionized water into the batching tank, and ventilate nitrogen to remove oxygen After 30 minutes, 20.00 g of 1% ammonium persulfate solution and the solution in the batching tank were distributed at a certain flow rate to a continuous nitrogen-filled device rotating at a certain speed, and reacted for 50 minutes. Finally, a colorless transparent colloidal PAM was obtained. After granulation, drying and crushing, a white powder is obtained. The obtained powder polymer has a molecular weight of 8.089 million, a dissolution time of 120 minutes, and a residual monomer content of 0.04%.

Embodiment 3

[0032] Mix 1700.00 g of 50% AM solution, 1935.00 g of acryloxyethyl trimethylammonium chloride (DAC, 80%), 120.00 g of urea, 0.96 g of disodium edetate, 0.50 g of isopropanol, and 4238.00 g Deionized water is added to the batching tank. After deoxygenating with nitrogen for 30 minutes, add 20 g of 1% ammonium persulfate solution to the batching tank and continue to bubbling with nitrogen for 10 minutes. This solution is combined with 10 g of 1% hydrogen sulfite. Sodium is distributed at a certain flow rate to a continuous nitrogen-filled device rotating at a certain speed, and reacted for a certain period of 55 minutes under normal temperature and microwave conditions. Finally, a colorless transparent colloidal PAM is obtained after granulation, drying and pulverization. White powder. The molecular weight of the powder is 13.45 million, the dissolution time is 120 minutes, and the residual monomer content is 0.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com