Corona-resistant polyimide/silica nano composite film and preparation method thereof

A technology of silicon dioxide and polyimide, which is applied in the field of corona-resistant polyimide/silicon dioxide nanocomposite film and its preparation, can solve the problems of two-phase compatibility and interface morphology defects, and the electric resistance of the composite film Halo performance improvement space is limited and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

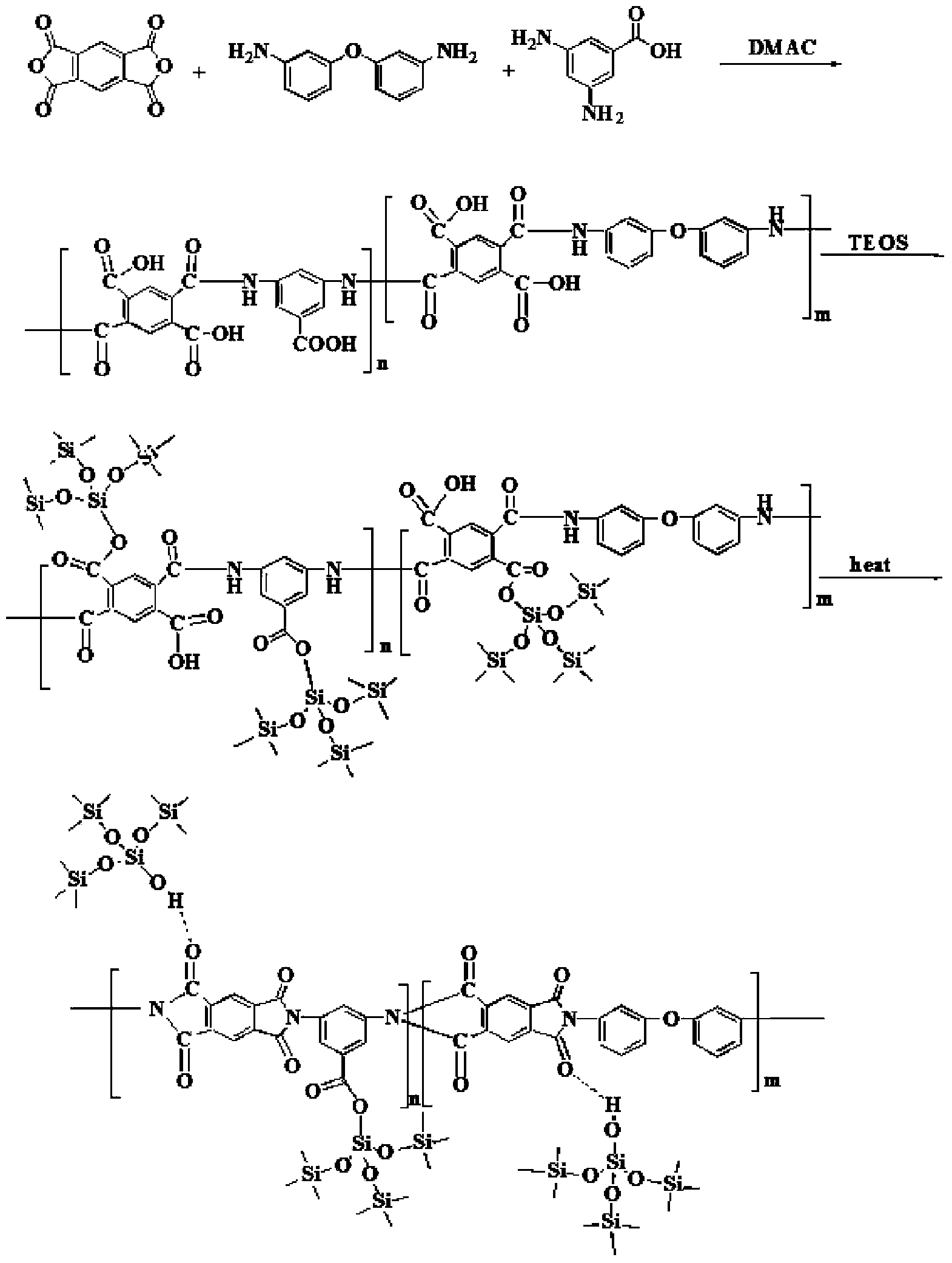

[0039] 1) The first step is to purify DABA, ODA, PMDA, and DMAc. Pretreatment methods include methods such as drying, sublimation, recrystallization and vacuum distillation;

[0040] 2) 6.8582 and 5.2100 grams of purified ODA and DABA (ie their molar ratio n ODA :n DABA =1) Dissolved in DMAc to form a diamine solution, 14.9800 grams of PMDA [the molar ratio of PMDA to diamine is n PMDA :n (ODA+DABA) =1.004:1] Add the DMAc solution of the above diamine in three batches, after the PMDA is dissolved, put the reaction system in an ice-water bath and stir for 6 hours, then continue to stir overnight at room temperature to obtain a transparent mass concentration It is 13% side chain carboxyl copolyamic acid (PAA) injection solution.

Embodiment 2

[0042] Weigh 10 grams of the PAA film injection solution prepared in Example 1, cast it on a clean and dry smooth glass plate (pre-adjusted level), and then follow the following temperature program (100 ° C for 1 h, 200 ° C for 1 h and 300 ℃ for 0.5 h) heating, during which PAA undergoes thermal imidization to obtain a polyimide (PMDA / ODA-DABA) film. The resulting film had a volume resistivity of 2.9 × 10 10 Ω·m, the dielectric constant is 3.6, the breakdown field strength is 201 kV / mm, and the corona resistance time is 4.2 h.

Embodiment 3

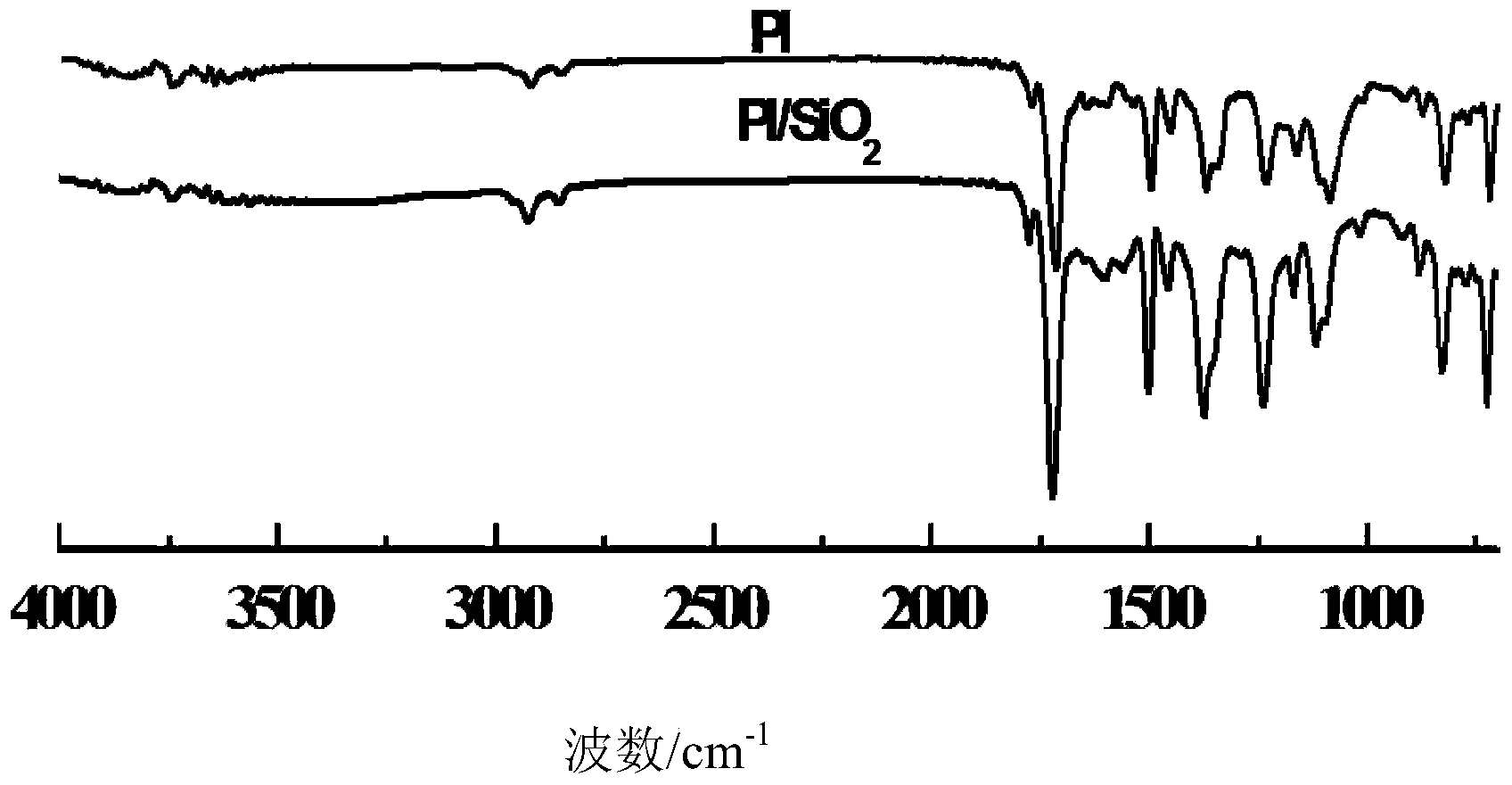

[0044] Take by weighing 10 grams of the PAA film injection solution prepared by Example 1, and press the SiO in the composite film 2 Add tetraethyl orthosilicate (TEOS) at a mass percentage of 5%, and then add a drop of dilute hydrochloric acid with a volume concentration of 1%. After stirring and reacting for half an hour, add distilled water dropwise (the amount added is 40wt% of DMAC ), react at room temperature for 16 h; cast film on a clean and dry smooth glass plate (pre-adjusted level), and finally make PAA heat sub- Amination, namely to get SiO 2 5% polyimide / silica nanocomposite film. The volume resistivity of the obtained nanocomposite film is 3.9×10 10 Ω·m, the dielectric constant is 3.3, the breakdown field strength is 195 kV / mm, and the corona resistance time is 8.5 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Breakdown field strength | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com