High-adhesiveness phenol aldehyde composite adhesive and preparation method thereof

A composite adhesive and high-adhesive technology, applied in the direction of polymer adhesive additives, adhesives, adhesive types, etc., to achieve low curing temperature, good gloss, and reduced release of free aldehydes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 0.5 mol of phenol, 0.25 mol of sodium hydroxide and 0.025 mol of aqueous solution into a round bottom flask, apply machine stirring and raise the temperature to 42°C, keep for 10 minutes, then add 80% formaldehyde solution (0.8 mol), within 15 minutes Raise the temperature to 70°C, add the remaining 20% formaldehyde to obtain a phenolic resin prepolymer; add chloromethylimidazole-polyether ionic liquid after 10 minutes, keep the temperature for 20 minutes, then slowly raise the temperature to 93°C, and keep the system for 60 minutes. Cool down to 70°C, dehydrate under reduced pressure, add ethanol to adjust the viscosity, the measured viscosity is 390mPa·s, immediately cool to 40°C, and discharge to obtain a phenolic composite adhesive.

[0035] Wherein the chloromethylimidazole-polyether ionic liquid accounts for 10% by mass of the phenolic resin prepolymer.

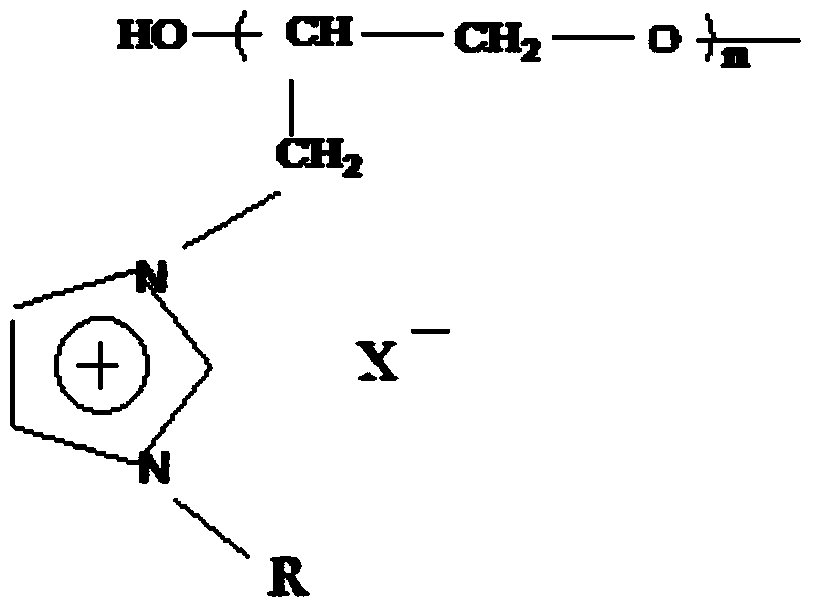

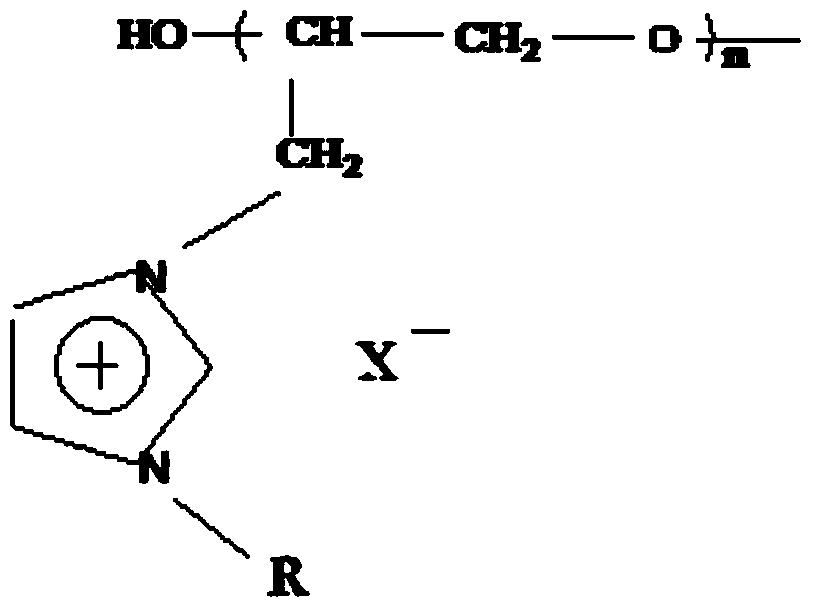

[0036] Chloromethylimidazole-polyether ionic liquid, the structural formula is as follows:

[0037] ...

Embodiment 2

[0040] Mix 0.5 mol of phenol, 0.25 mol of sodium hydroxide and 0.025 mol of aqueous solution into a round-bottomed flask, apply mechanical stirring and raise the temperature to 45°C, keep for 10 minutes, then add 80% formaldehyde solution (0.8 mol), within 15 minutes The temperature was raised to 70°C, and the remaining 20% formaldehyde was added to obtain a phenolic resin prepolymer; after 10 minutes, chloroethylimidazole-polyether ionic liquid was added. After keeping for 20 minutes, slowly raise the temperature to about 95°C, and after keeping for 60 minutes, cool the system down to 70°C, dehydrate under reduced pressure, add ethanol to adjust the viscosity, the measured viscosity is 410mPa·s, immediately cool to 40°C, and discharge to obtain phenolic formaldehyde Composite adhesive.

[0041] The specific steps of the lapped spline prepared in this example are the same as in Example 1, wherein the chloroethylimidazole-polyether ionic liquid accounts for 15% by mass of the...

Embodiment 3

[0045] The preparation method of this example is the same as Example 2, except that the ethylimidazole-polyether ionic liquid accounts for 20% by mass of the phenolic resin system, and the imidazole-type polyether ionic liquid used is anion BF 4 — imidazole polyether ionic liquid.

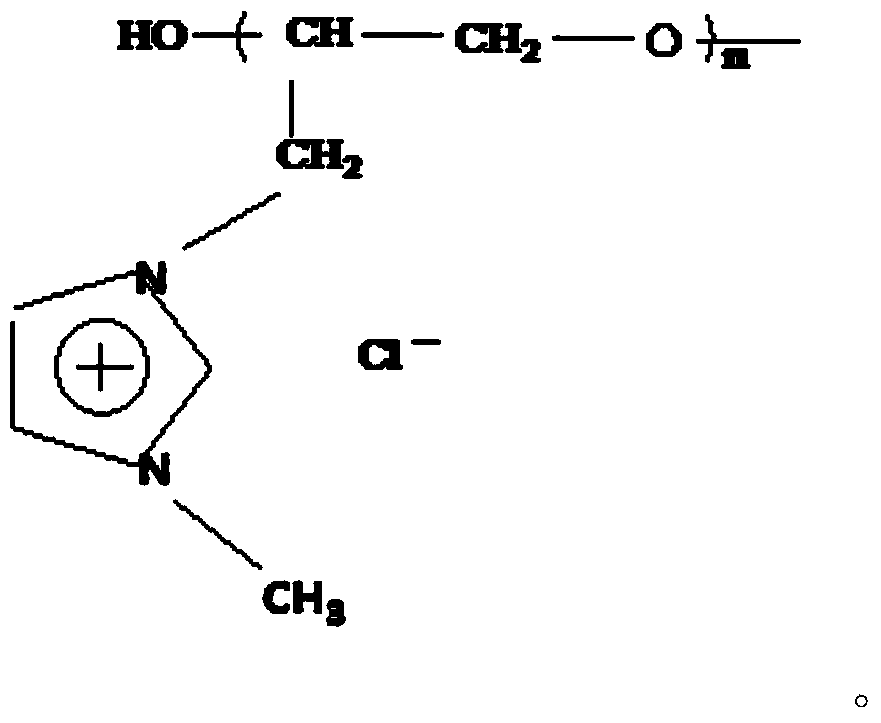

[0046] The resulting anion is Cl — Dissolve the chloroethylimidazole-polyether ionic liquid in dimethyl sulfoxide, stir evenly, add sodium tetrafluoroborate, react at 50°C for 24 hours, and perform anion exchange: after the ion exchange reaction, let stand and filter out chlorine Sodium chloride, then distilled under reduced pressure at 90°C and 0.1MPa to obtain the anion as BF 4 — The imidazole type polyether ionic liquid, structural formula is as follows:

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com